Fertilizer Rotary Screener/ Trommel Tongli

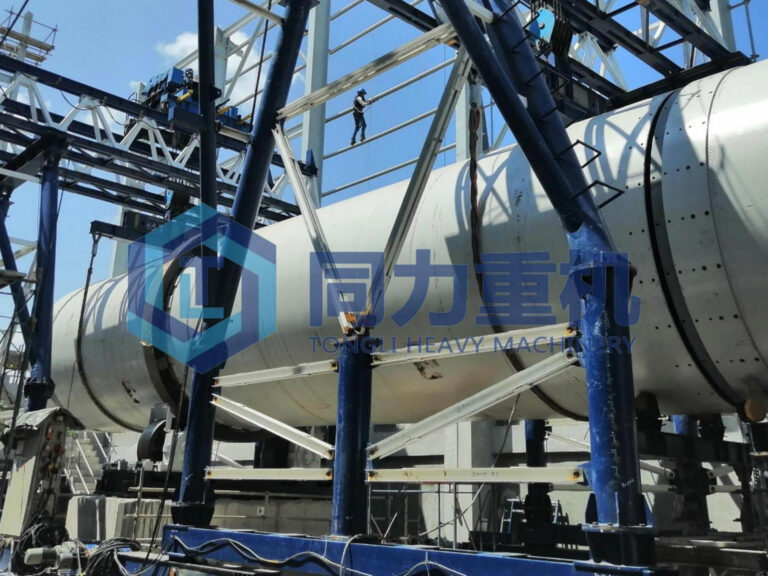

The fertilizer drum screening machine is an ideal equipment for compound fertilizer production plants

Rotary Screener/ Trommel

The Fertilizer Rotary Simplex Sifter is ideal for compound fertilizer production plants to separate the finished organic fertilizer from the finished compound fertilizer and those that do not meet the quality requirements for return to the granulator. The use of modular screens inside allows for easy maintenance and replacement, making them popular in the world fertilizer market!

Rotary Screener/ Trommel Pros

- Wide adaptability: Drums are widely used for screening all kinds of materials, whether it is fertilizer particles, wood particles, or other coal materials, can be successfully screened.

- Simple and diversified feeding methods: the feeding port of the drum can be designed according to the actual site, whether it is a belt, funnel, or other feeding methods, no need to take special measures to feed the material smoothly.

- High screening efficiency: As the equipment is equipped with a clearing mechanism, in the screening process, no matter how the material viscosity, humidity, or impurity, will not be clogged through the relative movement of the clearing plate and the body of the screen mesh, thus improving the efficiency of the screening equipment.

- Large screening capacity: under the same size, the circular area is larger than other shapes, and the effective screening area is large so that the material can fully contact with the screen.

- Low energy consumption: the motor power of the tumbler screen is small, 1/2 to 1/3 of other types of screen.

- Long service life: the machine is sturdy and durable, and its service life is longer than that of similar machines.

- Convenient maintenance: the working parts of the machine and the host adopt shaft-pin coupling transmission, easy to install dismantle, and maintain, and the machine can be used for the screening of organic fertilizer, composite fertilizer, and other fertilizers.

The Main Structure Of Fertilizer Rotary Screener/ Trommel

The rotary screening machine consists of five parts: hexagonal drum, frame, funnel, reducer and motor. After the fertilizer particles enter the drum, on the one hand, they are screened by the rotation of the drum, on the other hand, the big particles move forward along the slope of the drum and are screened gradually through different screens.

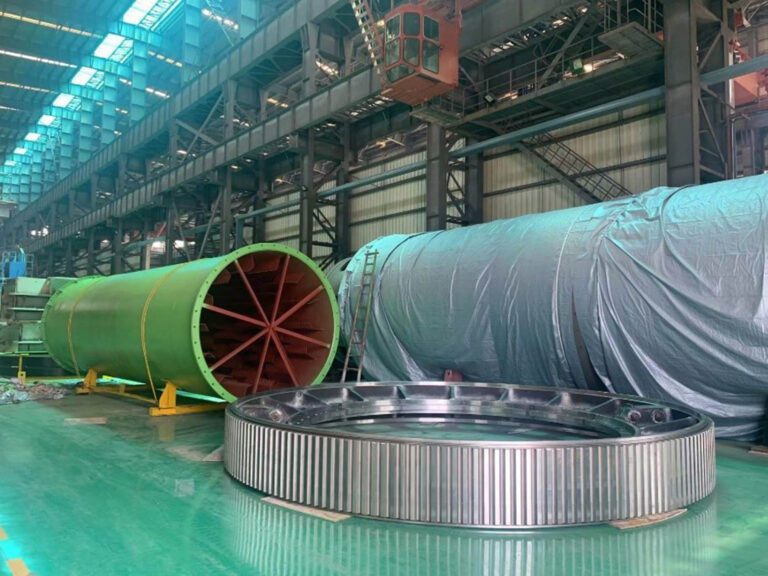

Frame: The frame is made of high quality carbon steel plate and channel steel, which meets the requirements of qualified certification and specialized technology.

Transmission part: belt pulley, triangle belt, transmission reducer to make the spindle rotating work. The structure of transmission part is simple, easy to assemble and maintain.

Sieve: It adopts combined sieve, which is installed on the spindle drum, and the materials are fed into the drum from the inlet, and the drum rotates to efficiently group the materials into finished products or substandard products that need to be returned for processing.

Rotary Screener/ Trommel

Rotary Screener

Vibrate Screener

Fertilizer Rotary Drum Cooler Applications

TONGLI NPK compound fertilizer granulator specification:

- ZJTL Series

- Diameter(mm)

- Length(mm)

- Capacity(t/d)

- Weight(t)

- Power(KW)

- ZJTL 2.5x20m

- 2500

- 20000

- 300

- 90

- 30

- ZJTL 2.8x20m

- 2800

- 20000

- 450

- 105

- 37

- ZJTL 3.0x25m

- 3000

- 25000

- 600

- 120

- 55

- ZJTL 3.2x25m

- 3200

- 25000

- 1000

- 135

- 132

- ZJTL 3.5x25m

- 3500

- 25000

- 1600

- 175

- 160

- ZJTL 4.0x30m

- 4000

- 30000

- 2500

- 230

- 200

- ZJTL 4.8x40m

- 4800

- 40000

- 3500

- 450

- 280

Product

What Else Does TONGLI offer?

How TONGLI process order?

Contact Via Email

Find our contact information via email or whatsapp

Sales Representative

Our experienced expert will get in contact with you

Fill out a quick questionnaire

For details of raw material and site condition so on

Making Proposal

Making customized fertilizer industry solution

Fabrication

Start manufacturing after everything are checked

Commission

Send our most experienced installation engineer

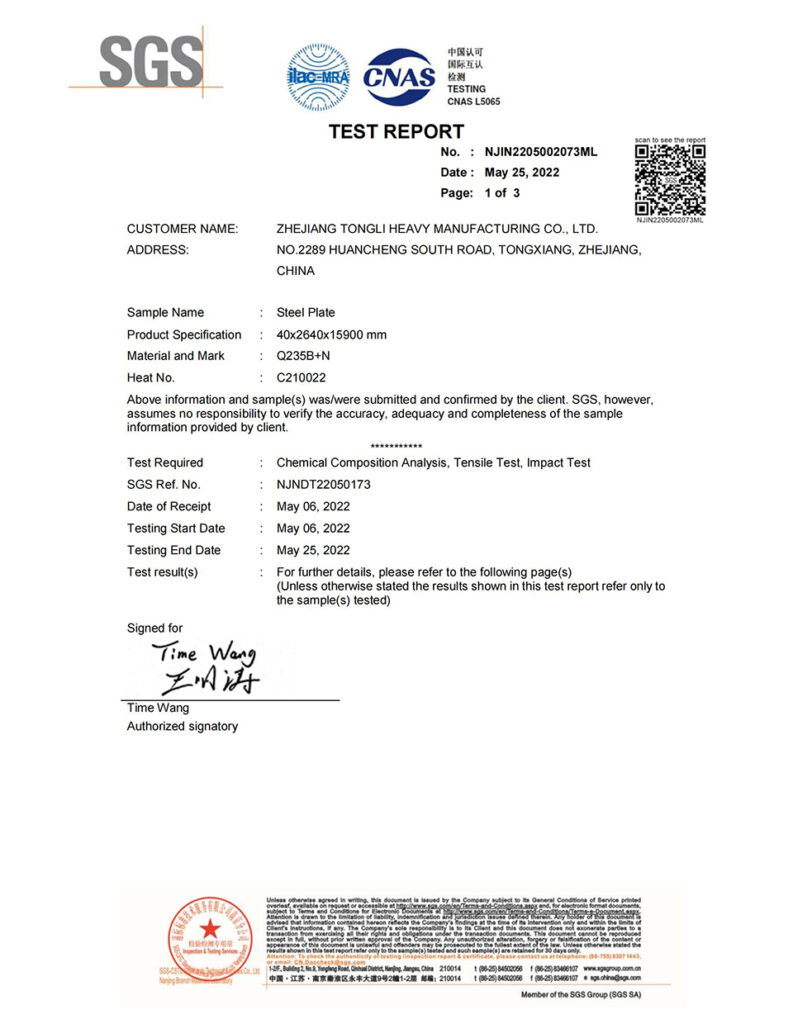

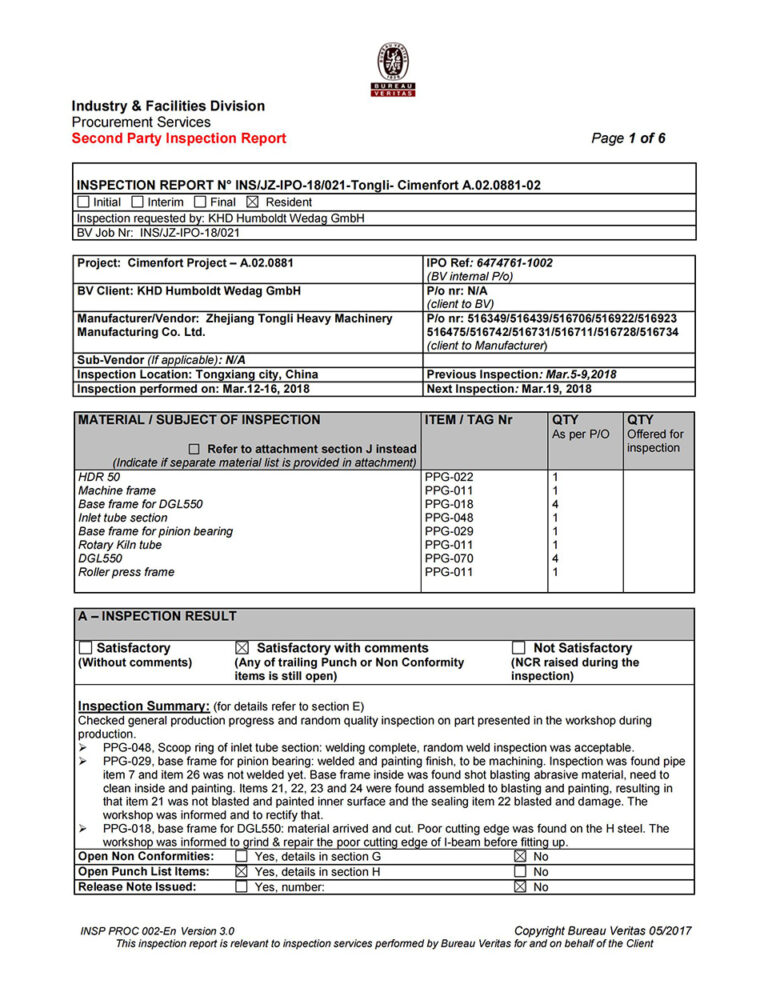

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas

The only place where you’ll get the perfect solution for fertilizer industry needs.

No.2289 huancheng south road, tongxiang, zhejiang, China 314500

PRODUCTS

- Granulator

- Dryer

- Cooler

- Coater

- Trommel

- Automatic-batching system

- Auto-palletizing system

- Auto-Packaging system

- Auto-bagging machine

- Dedusting bag filter system

- Crusher

- Bucket elevator

- Belt Conveyor

- Centrifugal blower

- Hot air generator

SOLUTIONS

- NPK compound fertilizer production line

- Organic-inorganic fertilizer production line

- High tower fertilizer prilling line

- BB fertilizer blending line

- Roller press round granule extrusion line

- Roller press irregular granule extrusion line