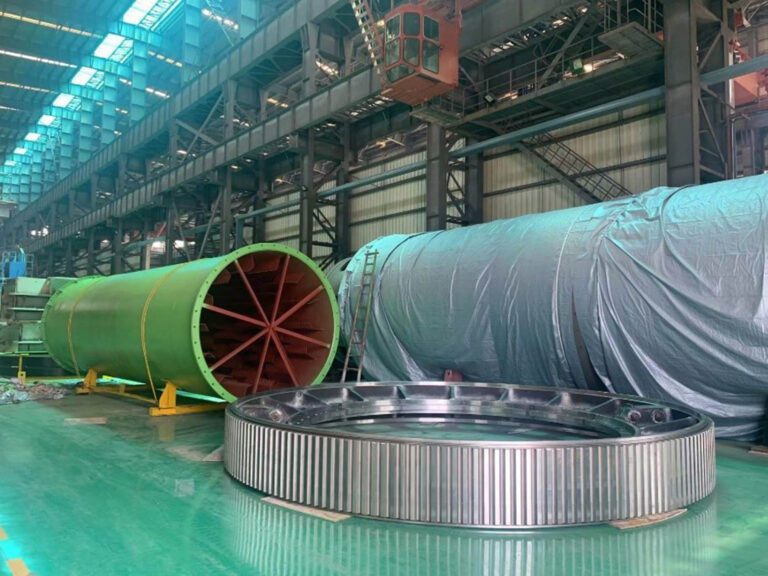

Roller Extrusion Granulator

NPK Roller extrusion granulator for fertilizer lines

Roller extrusion granulator is the key equipment for compound fertilizer granulation. Applicable to the production of high, medium and low concentration compound fertilizer, this granulator adopts room temperature without drying process, less investment, quick results, good economic benefits, is a set of granulation, molding, screening in one of the equipment.

Difference between Roller extrusion granulator and other granulators

Different Methods

Double-roller press granulator adopts dry granulation, other granulators are usually method granulation, the advantage of double-roller press granulation is reflected in the absence of the need to use the dryer to dry the fertilizer particles!

Different Working Principles

Roller pelletizer adopts extrusion and then produces finished products, while other equipment produces finished products by rotating.

Shape Difference

The shape of the product produced by rotary granulator is generally spherical, while the double-roller granulator can produce such shapes as pillow, stick, pill, walnut, square and so on.

Advantages of Roller Extrusion Granulator

compact structure, light weight, smooth rotation, high precision, high rigidity can be pressed different shapes / sizes of materials.

Wide range of application, applicable to more than 20 kinds of raw materials, can produce 30 + different products.

The granulation rate of roller compaction granulator is high, more than 85%.

Energy saving and consumption reduction, no waste water and gas emission.

What Materials Are Suitable For Granulation with Double-roller Granulator?

Compound fertilizer

Compound fertilizer granules such as zinc sulfate, potassium sulfate (SOP), potassium oxide, ammonium chloride, ammonia sulfate, magnesium sulfate, sodium chloride, etc. can be produced by using double roll granulator.

View ServiceOrganic fertilizer

With the help of double roller granulator, you can make organic fertilizer pellets from chicken manure, pig manure, raw manure and other animal poultry manure waste.

View Service

Parameters of Roller Extrusion Fertilizer Making Machine

|

Model |

Dimension

L x W x H(mm) |

Output (t/h) |

Power (kw) |

Material Moisture Content |

Feed Size (mm) |

|

Tongli-1.0 |

1300x750x1300 |

0.75-1 |

15 |

2%-5% |

≤0.5 |

|

Tongli-1.5 |

1450x840x1500 |

1-1.5 |

22 |

2%-5% |

≤0.5 |

|

Tongli-2.0 |

1530x950x1650 |

1.5-2 |

37 |

2%-5% |

≤0.5 |

What Else Does TONGLI offer?

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas