Dryer

What is the working principle and adventages of a rotary drum dryer?

- High Capacity: Rotary drum drying machine can handle large quantities of material.

- Uniform Drying: The tumbling action of the drum ensures uniform drying and consistent product quality.

- Versatility: Rotary drum dryers can be used to dry a wide range of materials, including bulk solids, powders, granules, and slurries.

- Energy Efficiency: Rotary drum dryers can achieve high thermal efficiency and optimizing airflow patterns, leading to lower energy consumption compared to other drying methods.

INtroduction to npk compound fertilizer rotary drum dryer/drying machine.

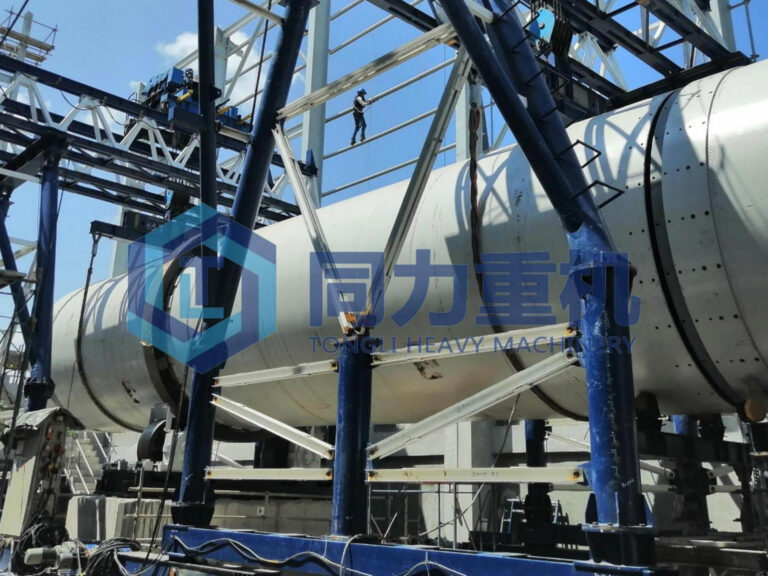

The drum dryer is a piece of equipment specially developed by tongli for the drying of npk compound fertilizer. Since the 1990s, tongli has provided drum dryers of different specifications and models to the world’s top 500 fertilizer companies.

Under the heating of the heat source and the rotation of the drum, the material is fully and evenly dried in the equipment, thus ensuring the purpose of controlling the moisture content of the compound fertilizer. Tongli’s drum dryers are widely used in the production of organic fertilizers, inorganic fertilizers, water-soluble fertilizers, and organic-inorganic mixed fertilizers prodution plant.

What types of compound fertilizers can be dried by using the rotary drum dryer?

- NPK Fertilizers: These are compound fertilizers containing three main nutrients: nitrogen (N), phosphorus (P), and potassium (K).

- Organic-inorganic compound fertilizers: That combine synthetic nutrients with organic materials such as compost, manure, or bio-based residues.

- DAP (Diammonium Phosphate)Rotary drum dryers can effectively dry DAP fertilizers to improve their handling and storage characteristics.

- Ammonium Nitrate-based Fertilizers: Drying ammonium nitrate-based fertilizers helps prevent caking and ensures product quality during storage and transportation.

- Urea-based Fertilizers: drum dryers can effectively dry urea-based fertilizers to reduce moisture content and improve handling properties.

What are the different types of rotary drum dryer?

- Direct Heat Rotary Drum Dryer: Use direct heat transfer methods, suitable for materials(inorganic npk compound fertilizer) that can withstand high temperatures and direct contact with the heating medium.

- Indirect Heat Rotary Drum Dryer: In contrast to direct heat dryers, indirect heat dryers use an external heat source to transfer heat to the material indirectly like steam tubes.

- Counter-Current Rotary Drum Dryer: In this design, the material and the drying air flow in opposite directions. The wet material enters at the far end of the drum, while the hot gases enter from the opposite end.

What are the design considerations for a fertilizer rotary drum dryer?

- Airflow Design: Design the airflow patterns within the dryer to ensure efficient moisture removal while minimizing energy consumption and heat loss.

- Integration with Upstream and Downstream Processes: Ensure compatibility and seamless integration of the dryer with upstream processes granulation and downstream process such as cooling and screening.

- Moisture Control: Incorporate sensors and control systems to monitor and control the moisture content. This involve feedback control loops and interlock system to adjust parameters of inlet air temperature and drum speed.

- Knocking device is typically used to prevent material buildup and ensure proper flow of dried product.

What are the material selection consideration of TONGLI fertilizer dryer?

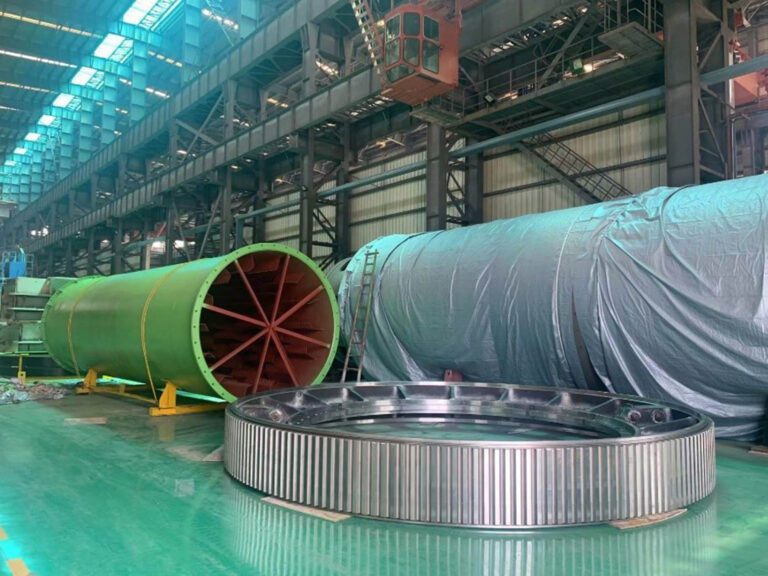

a rotary dryer riding ring is typically made of durable materials such as cast steel or forged steel. It is designed to withstand the weight of the rotating drum and the materials being processed within the dryer.

- TONGLI has Its own foundry, others don’t.

- TONGLI use high standard metal material.

- TONGLI use Germany spectrometer to control composition of molten metal.

- TONGLI use Alkali phenolic resin sand and three-phase electric arc furnace ensure casting quality.

What is the supporting device of a rotary drum dryer?

a rotary dryer supporting device is a component designed to provide support and stability to the rotating parts of the dryer machine.

- State-of-art design, we don’t take short cuts, we design the support device as reliable as possible according to the highest industry standard.

- Stability and Balance: The supporting device provides the structural integrity necessary to support the weight of the rotating drum

- High quality: all metal casting and welding are heat treated and Magnetic testing performed.

- Rotational Accuracy: A high-quality supporting device helps maintain the proper alignment and rotational accuracy of the drum. Any misalignment or imbalance in the supporting device can lead to uneven rotation, causing uneven drying

What are the dedusting & HSE environmental considerations of dryer?

Dedusting helps industries comply with air quality standards and regulations by reducing harmful emissions. A rotary dryer hood cover is a protective casing that connects to the bag filter, it helps to contain the drying process within a closed environment, preventing the dispersion of dust, particles, or vapors into the surrounding area.

Dust and particulate buildup in exhaust systems can lead to equipment corrosion, fouling, and reduced efficiency. Dedusting helps protect the rotary dryer and associated equipment by preventing damage caused by abrasive particles. Dedusting also improves energy efficiency by maintaining optimal airflow through the dryer system.

TONGLI NPK compound fertilizer granulator specification:

- ZJTL Series

- Diameter(mm)

- Length(mm)

- Capacity(t/d)

- Weight(t)

- Power(KW)

- ZJTL 2.5x20m

- 2500

- 20000

- 300

- 90

- 30

- ZJTL 2.8x20m

- 2800

- 20000

- 450

- 105

- 37

- ZJTL 3.0x25m

- 3000

- 25000

- 600

- 120

- 55

- ZJTL 3.2x25m

- 3200

- 25000

- 1000

- 135

- 132

- ZJTL 3.5x25m

- 3500

- 25000

- 1600

- 175

- 160

- ZJTL 4.0x30m

- 4000

- 30000

- 2500

- 230

- 200

- ZJTL 4.8x40m

- 4800

- 40000

- 3500

- 450

- 280

How TONGLI process order?

Contact Via Email

Find our contact information via email or whatsapp

Sales Representative

Our experienced expert will get in contact with you

Fill out a quick questionnaire

For details of raw material and site condition so on

Making Proposal

Making customized fertilizer industry solution

Fabrication

Start manufacturing after everything are checked

Commission

Send our most experienced installation engineer

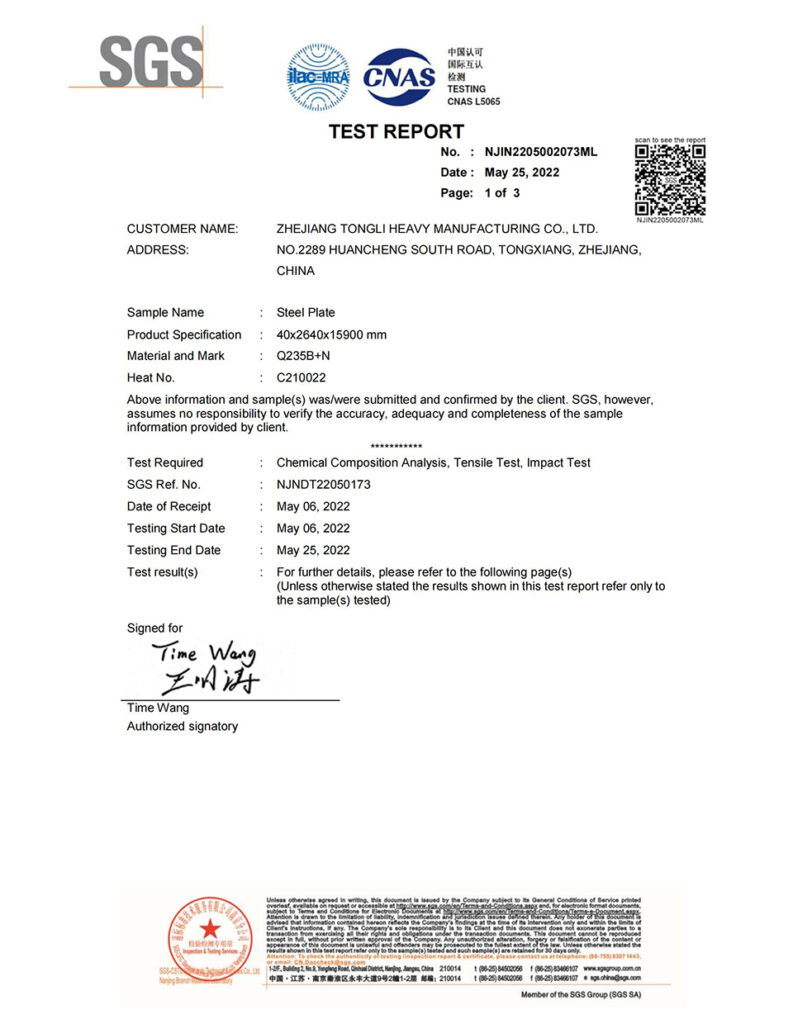

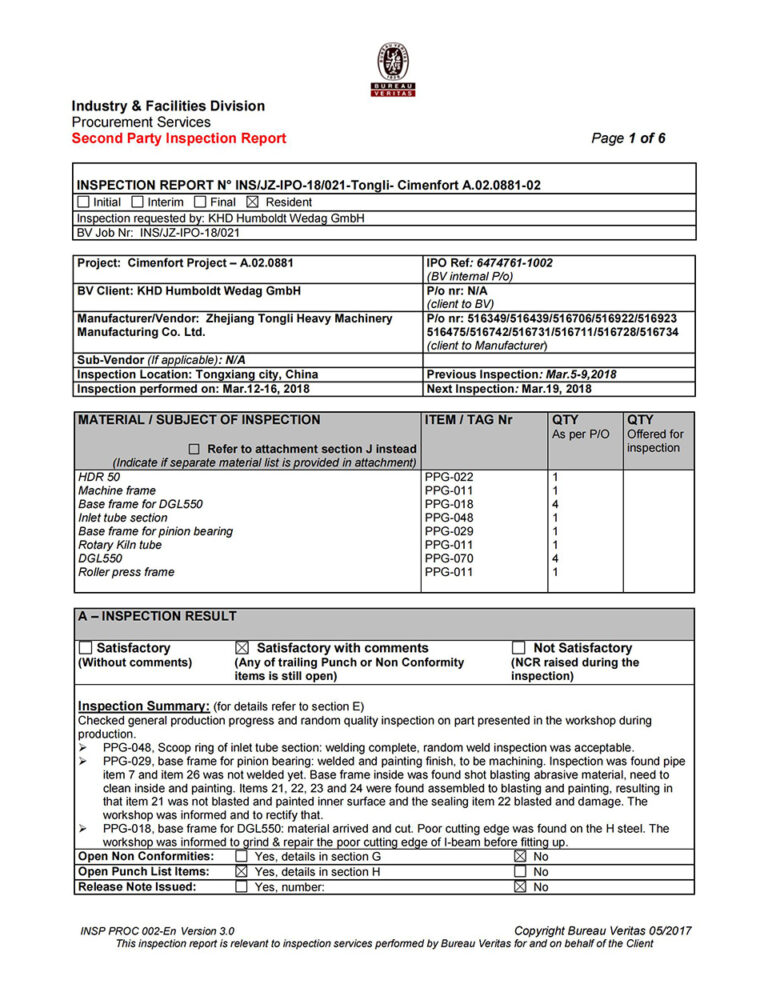

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas