Fertilizer Cooling Equipment

Cooling Equipment Fertilizer Manufacturing Equipment

The rotary cooler is used in the production of compound fertilizers to cool granular fertilizers. The use of rotary coolers in conjunction with dryers can greatly increase the cooling speed, reduce labor intensity, increase production.

Advantages of Fertilizer Cooling Equipment

- High efficiency and capacity: Cooling equipment can quickly and effectively reduce the material temperature to meet the requirements of the production process. Advanced design and manufacturing processes ensure the efficient operation of the cooling equipment and maximize production efficiency.

- Low Maintenance Costs: Cooling equipment is simple in structure and easy to maintain. High-quality components and materials ensure the durability and reliability of the cooling equipment, reducing maintenance costs and repair time.

- Simple operation and high stability

: The cooling equipment adopts intelligent control system, which is simple to operate and easy to control. - Wide applicability: The cooling equipment can be used to cool a variety of materials, including powders, granules, liquids, etc. It can meet the requirements of different materials and production processes.

- Can be used for a variety of fertilizers: The equipment can be used to produce a variety of types of fertilizers, including compound fertilizers, single fertilizers, mixed fertilizers and so on.

Briquette Granulator Applicable materials

Cooling Cement Clinker

In the cement production process, clinker needs to be cooled to the right temperature before it can be ground and packaged. Cooling equipment can quickly and effectively reduce the clinker temperature, improve cement production efficiency and reduce energy consumption.

View ServiceFertilizer production equipment

Compound fertilizer is one of the commonly used fertilizers in agricultural production. Fertilizer production equipment can mix many kinds of raw materials in proportion, and produce high quality compound fertilizer through granulation, drying, cooling and other processes.

View Service

Compound fertilizer rotary granulator design principle

- Countercurrent heat transfer: material and airflow in the reverse direction, improve heat transfer efficiency, shorten the cooling time can reduce energy consumption.

- Efficient heat dissipation: The internal structure adopts a multi-layer structure, internal lifting device and other measures are conducive to the contact between the material and the cooling medium to realize rapid heat dissipation.

- Uniform air volume: Balanced and stable cooling airflow ensures a uniform cooling effect.

- Suitable residence time: The residence time of the material in the cooler is optimized, which can cool thoroughly and avoid excessive residence.

- Large capacity: Overload resistant, energy efficient, and reduces drying costs.

- Expandability: Designed with a margin to accommodate increased throughput.

- Controlled Discharge: Designed to prevent clogging and ensure stable discharge of cooled material.

- Insulation design: Reduce heat loss and improve energy efficiency.

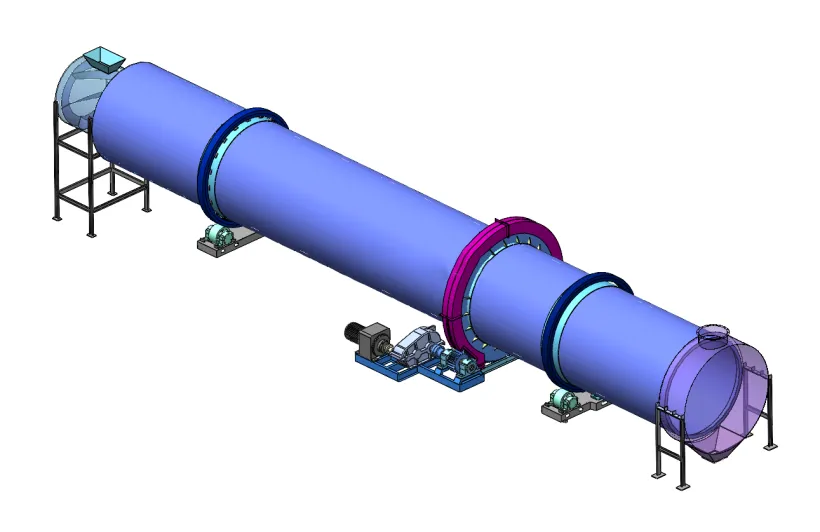

Compound fertilizer cooler structure

Compound Fertilizer Rotary Cooler is a kind of equipment used to produce compound fertilizer. It can be different according to the specific design, and generally consists of the following parts: riding ring, waist gear, support device, pinion gear, cover, gear cover, shell, transmission device, and so on.

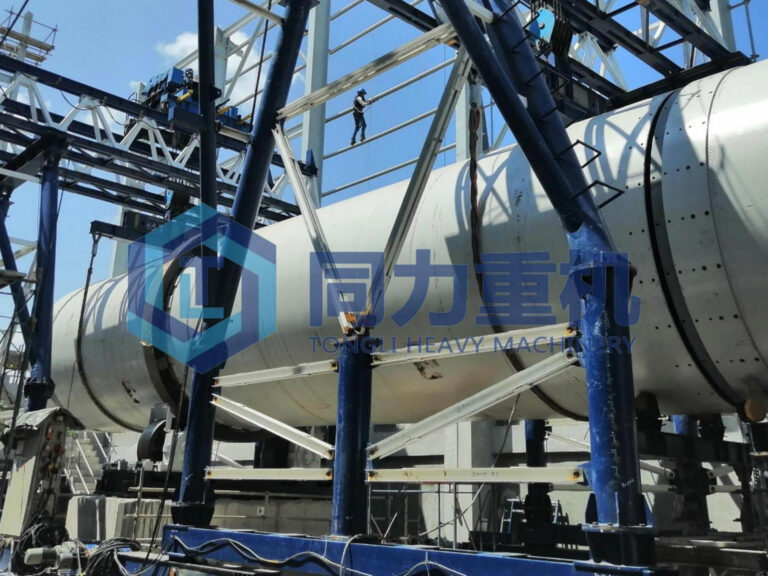

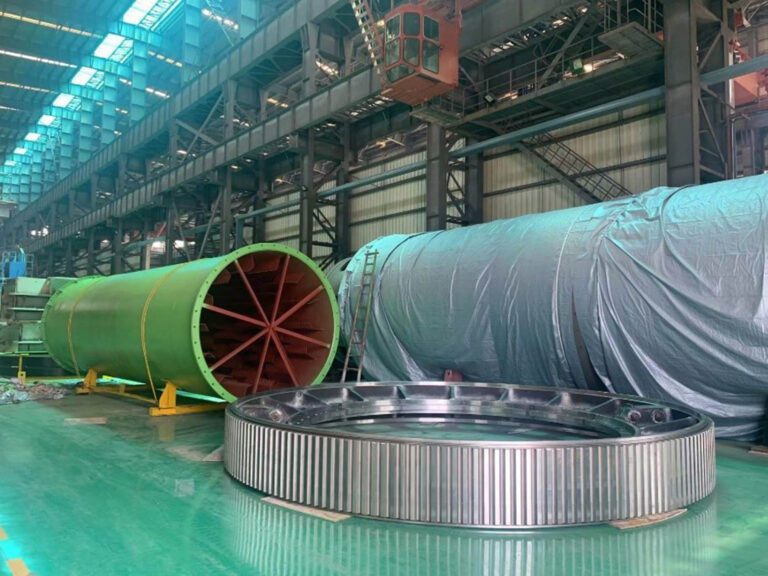

Cooler Shell

The cooler shell is a thick, steel cylindrical structure providing strength and rigidity to withstand high temperatures. It contains materials and gases during cement manufacturing. Inside, it has refractory lining, usually bricks or castable, for insulation. Tongli cooler shells have smooth edges for enhanced sealing and extended service life.

Cooler Flights

Cooler flights, or lifters, are inclined, curved structures inside the rotary cooler. These flights lift and drop materials as the drum rotates, aiding in moisture removal through cooling.

Riding Rings (Tyres)

Riding rings, usually 2-3 per cooler, support the shell and facilitate smooth rotation. These rings are point-welded with padding for added strength and weight distribution.

Girth Gear

The girth gear is a large ring gear mounted on the cooler shell, driven by a pinion gear to rotate the cooler. It forms the primary drive unit.

Supporting Device

The supporting device consists of supporting and thrust rollers, made in-house for guaranteed quality. These rollers are machined and heat-treated for reliable performance.

Thrust Roller

The thrust roller supports the cooler’s weight and maintains axial alignment. Positioned on the downhill side, it ensures proper alignment during rotation.

Bearing Housing

The bearing housing supports the cooler’s trunnion bearings, which allow smooth rotation under high loads and temperatures. It ensures proper alignment and stability.

Transmission Device

The transmission device includes main and auxiliary transmissions, mechanical/hydraulic thrust rollers, motor, and gearbox. Tongli’s design enhances equipment lifespan and safety.

Cooler Hood Cover

Located at the discharge end, the hood cover seals heat and gases. Tongli uses SS304 lining and ceramic felt to prevent heat leakage, maintaining negative pressure operation.

PLC Control System

The PLC system monitors and controls critical parameters like temperature, rotation speed, and air flow. Integrated with the factory’s PLC system, it ensures optimal cooler performance and product quality.

Specifications of compound fertilizer cooler

Specification: | Capacity: (t/day) | Slope | Thrust Type | Power: (kw) | Weight: (tons) |

Φ2.5×25 | 300 | 3.5 | Mechanical | 55 | 95 |

Φ2.8×25 | 450 | 3.5 | Mechanical | 100 | 105 |

Φ3.0×30 | 600 | 3.5 | Mechanical | 100 | 120 |

Φ3.2×30 | 1000 | 3.5 | Hydraulic | 160 | 160 |

Φ3.3×30 | 1200 | 4 | Hydraulic | 160 | 170 |

Φ3.5×35 | 1600 | 4 | Hydraulic | 220 | 180 |

Φ4.0×40 | 2500 | 4 | Hydraulic | 315 | 230 |

Φ4.3×35 | 3500 | 4 | Hydraulic | 400 | 320 |

Φ4.8×45 | 5000 | 4 | Hydraulic | 630 | 470 |

Φ5.0×45 | 6000 | 4 | Hydraulic | 710 | 495 |

Φ5.6×50 | 8000 | 4 | Hydraulic | 800 | 665 |

Φ6.0×55 | 12000 | 4 | Hydraulic | 900 | 865 |

Φ6.5×55 | 15000 | 4 | Hydraulic | 1200 | 1115 |

What Else Does TONGLI offer?

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas