Fertilizer Cooler Machines

Tongli

Rotary drum cooler is used in compound fertilizer production lines and organic fertilizer production lines to cool the fertilizer with certain temperatures and particle sizes.

Rotary Drum Cooler

A rotary drum cooler is used for cooling fertilizer with certain temperatures and fertilizer industries, the fertilizer cooler has been an essential part of Sulzer production and it consists of an otcvinder spiral pate citing board hooer and cooinacooling pine system he rotative drum coocoolingina machine can combine with the rotary diver to remove the dust and clean the exhaust together, which can improve the cooling efficiency and the rate of thermal enroll utizationreduce labor intensity, and further remove the moisture of the fertilizer. Generally, the inlet temperature of materials is 60″-80″, while the outlet temperature is less than 40″, Besides, the fertilizer cooling machine manufactured by us can also be used to cool other powder and granules materials. A rotary

Features of Fertilizer Rotary Cooling Machine

- Compact structure, easy maintenance, reliable performance, and low energy consumption.

- Reasonable distribution and angle of lifting plate, so that the material and cooling air maximize the heat exchange, improve cooling efficiency, and cooling effect.

- strong adaptability, suitable for processing particles with wide particle size distribution.

- A variety of models are available and can be customized according to customer requirements.

- The rotating speed of the simplified body can be adjusted according to the needs.

- the use of high-quality wear-resistant materials, greatly improves the service life of the machine.

- The reasonable design of the lifting plate makes the maximum heat exchange between high-temperature material and cooling air, improves the cooling efficiency, and makes the material cool evenly.

- The important parts of the machine transmission part are made of high-quality steel, after strict quality requirements, the transmission deceleration device adopts nylon pin coupling to transfer transmission.

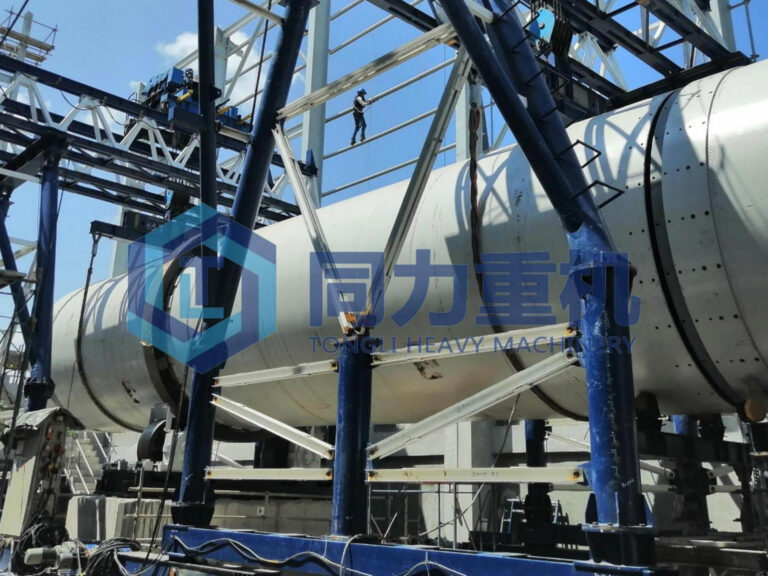

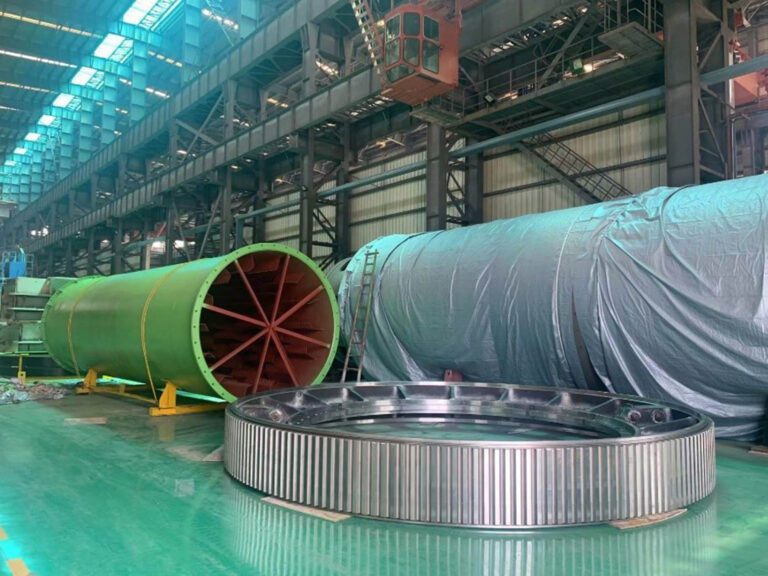

Rotary cooler parts

1: Other equipments include: material discharge port, raw material feeding chute, coupling guard, bearing seat and product discharge.

3: The gears fixed on the machine body are made of high-tech wear-resistant materials, which greatly prolongs the service life of the machine.

4: Rolling belt is fixed on both sides of the machine, supporting the whole body.

2: The gear rack is welded with high-quality channel steel, and the main motor and reducer mounted on the gear rack adopt IS0 national inspection-free products with reliable quality.

4: The machine body is welded with high-quality medium carbon steel plate, and the lifting plate in the machine body is made of high-quality wear-resistant material.

5: Other equipments include: material discharge port, raw material feeding chute, coupling guard, bearing seat and product discharge.

Cooler Products

Rotary coolers

Indirect rRotary Coolers

Fertilizer Rotary Drum Cooler Applications

Technical Data of Fertilizer Rotary Drum Cooling Machine

| Model | Shell Inner Diam (mm) | Shell Length (mm) | Shell Inclination (0) | Shell Rotation Speed (r/min) | Feed Temperature (℃) | Discharge Temperature (℃) | Motor Model | Motor Power (kw) | Motor Rotation Speed (r/min) | Decele Vators Model |

| ALCLQ10100 | 1000 | 10000 | 2-5 | 4.6 | 60-80 | <40 | ALCY 132m-4 | 7.5 | 1440 | ALCZQ350 |

| ALCLQ12120 | 1200 | 12000 | 2-5 | 4.6 | 60-80 | <40 | ALCY 132m-4 | 7.5 | 1440 | ALCZQ350 |

| ALCLQ15120 | 1500 | 12000 | 2-5 | 5 | 60-80 | <40 | ALCY 160L-4 | 15 | 1440 | ALCZQ400 |

| ALCLQ15150 | 1500 | 15000 | 2-5 | 5 | 60-80 | <40 | ALCY 160L-4 | 15 | 1440 | ALCZQ500 |

| ALCLQ18160 | 1800 | 16000 | 2-5 | 5 | 60-80 | <40 | ALCY 200L1-6 | 18.5 | 970 | ALCZQ500 |

| ALCLQ20200 | 2000 | 20000 | 2-5 | 5 | 60-80 | <40 | ALCY 200L1-6 | 22 | 970 | ALCZQ650 |