Briquette/ Extrusion Granulator

Extrusion Granulator

Briquette Granulator is an efficient and versatile machine designed to convert powdered materials into solid shapes. The demand for rapid development of modern industry and the degree of production automation, “powder products granularity” has become the world’s powder post-processing technology of the inevitable trend.

Difference Between Extrusion Granulator And Other Granulators

Specific Functionality:

Specifically designed to produce solid briquettes from powdery or granular materials, making it ideal for creating fuel briquettes from biomass, coal, and other materials.

Material Compatibility

Capable of handling a wide range of materials, including biomass, charcoal, coal, and other waste materials, transforming them into solid briquettes.

Production Process

Often includes additional processes like binding, pressing, and shaping to ensure the briquettes are solid and durable.

Advantages of Briquette Granulator

Briquette Granulator Applicable materials

Compound fertilizer

potassium sulfate, potassium chloride, Russian red potassium, compound fertilizers, ammonium chloride, potassium nitrate, monoammonium phosphate, diammonium phosphate, ammonium sulfate, ammonium bicarbonate.

View ServicePowder materials

antioxidant, bromochlorohydantoin, sodium cyanide, sodium dichloroisocyanurate, sodium trichloroisocyanurate, cyanuric acid, bleaching powder, zinc oxide, lead oxide, potassium carbonate, strontium carbonate, calcium chloride, calcium hydroxide phosphate, sodium metasilicate, sodium orthosilicate, cryolite, aluminum fluoride, brake powder, rubber-plastic auxiliaries, silica, calcium aluminum, calcium bicarbonate, heavy calcium, calcium chloride, carnallite, phosphorite powder, metal powder, feed additives, Arsenopyralid, nicotinic acid, nicotinic acid amine, pharmaceutical intermediates, steelmaking auxiliaries, snow-melting agent, puffing, alumina powder, phosphogypsum, desulfurization gypsum, mineral processing agent, environmental protection materials, as well as graphite, carbon black and so on.

View Service

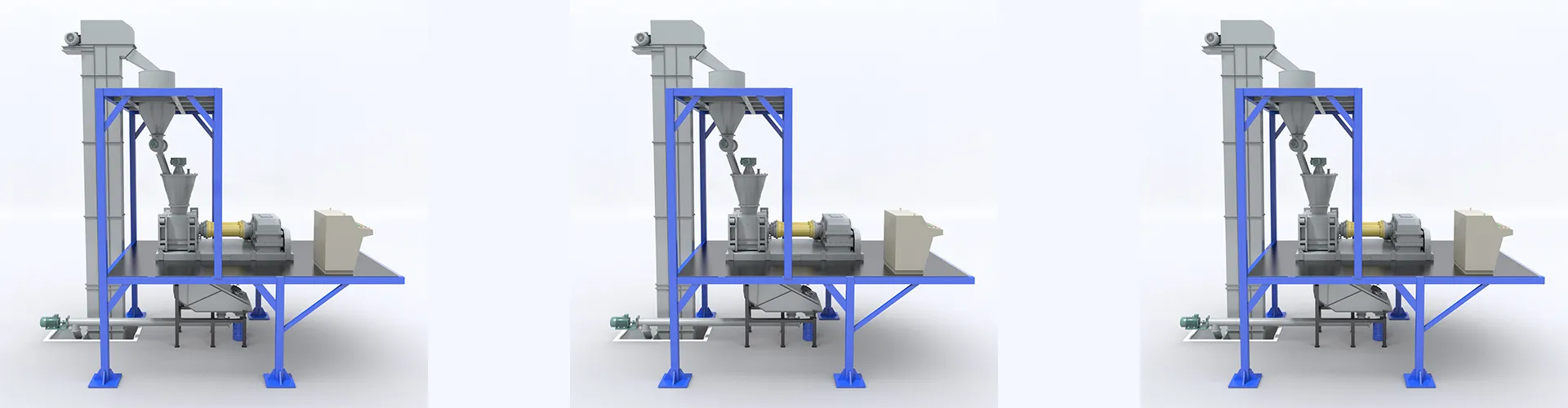

Product Schematic

Adopting dry roller pressing process technology, the powdery material with moisture content lower than 5% is compressed into flakes or blocks, and then after crushing, granulation and screening process, the granular material that meets the use requirements is obtained. The working principle of the machine mainly includes the following steps:

- Material feeding: The raw material is fed into the feeding hopper evenly through the dosing feeder.

- Roll forming: The material in the feed hopper enters the roll gap through self-weight and forced feeding. The rolls rotate in opposite directions at the same speed and come into close contact with each other under the pressure of a hydraulic cylinder. The surface of the rolls has regularly arranged holes, and the material is gradually compressed and molded under the pressure of the rolls.

- Crushing: the rolls pressed flake or block material falls into the crusher, crushed into particles to meet the particle size requirements.

- Screening: The crushed granular material passes through the sieving machine to get the finished granular material which meets the requirements of particle size, and the unqualified granular material is sent back for re-pressing.

What Else Does TONGLI offer?

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

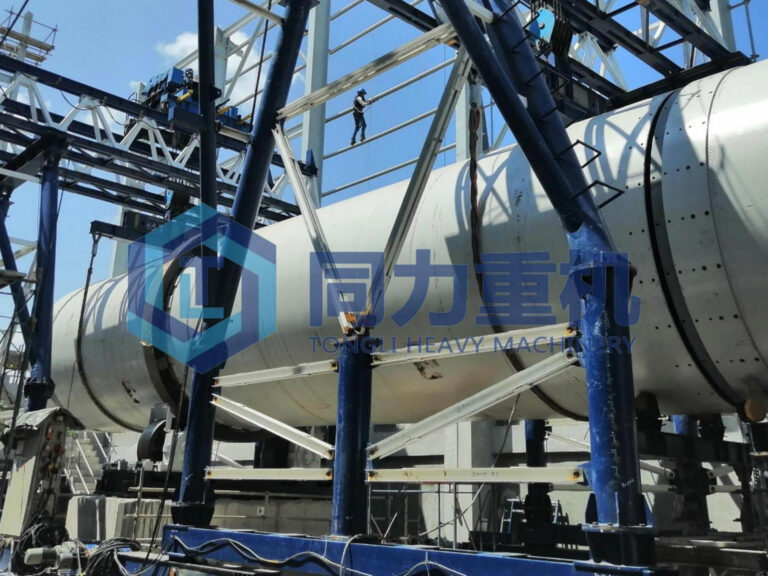

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

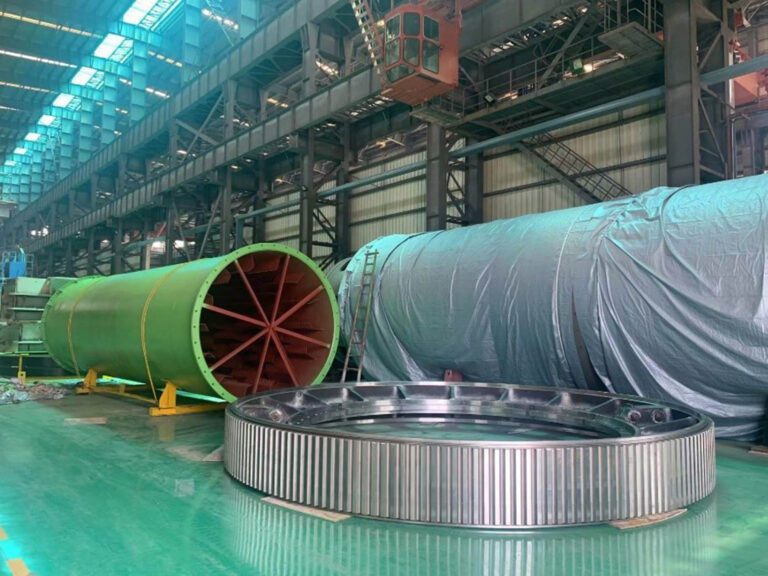

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas