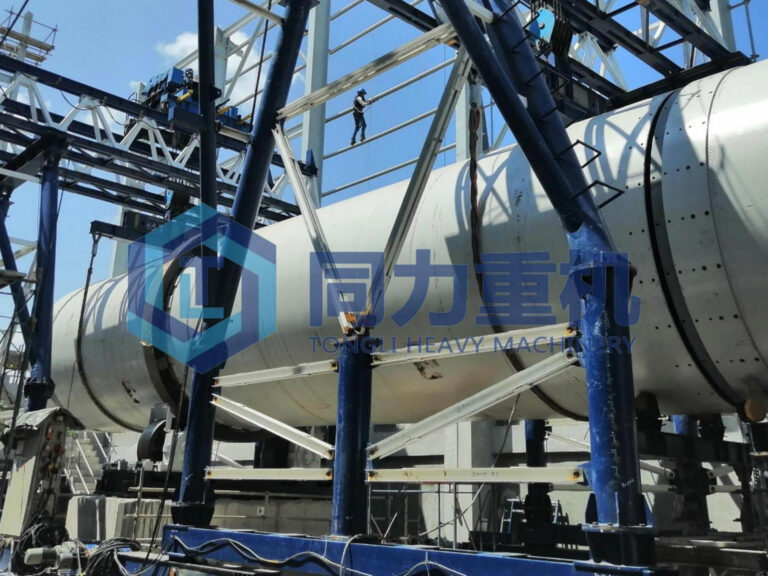

BB(bulk blending) Fertilizer

Production Line

Tongli's BB(bulk blending) fertilizer production lines with its diversified formulas and precise batching system allow you to produce any fertilizer you want.

BB(bulk blending) fertilizer plant Equipment List

Crushing Equipment

- Bulk Crusher

- Cage Crusher

- Chain Crusher

- Ton Bag Crusher

Batching system

- Electronic belt scale

- Finished product weighing scale

Coating Equipment

- Fertilizer Coating machine

- Coating agent melting tank

- Metering Pump

Conveying Equipment

- Belt Conveyor

- Bucket Elevator

- Scraper Conveyor

- Screw Conveyor

Automatic Control System

- Automatic-batching system

- Automatic-packaging system

- Automatic-bagging system

- Automatic-palletizing system

Dust Removal Equipment

- Bag House Dust Collector

- Cyclone Dust collector

- Glass Fiber Chimney(FRP)

- Tail Gas Washing Tower(FRP)

BB Bulk Blending fertilizer plant technical parameters

| Item | Prod Capacity (t/h) | Specification | Power | Quantity(set) |

|---|---|---|---|---|

| Electric belt scale auto batching system | 5~30 | B650 x 1700mm | 1.1+1.1kw | 7 |

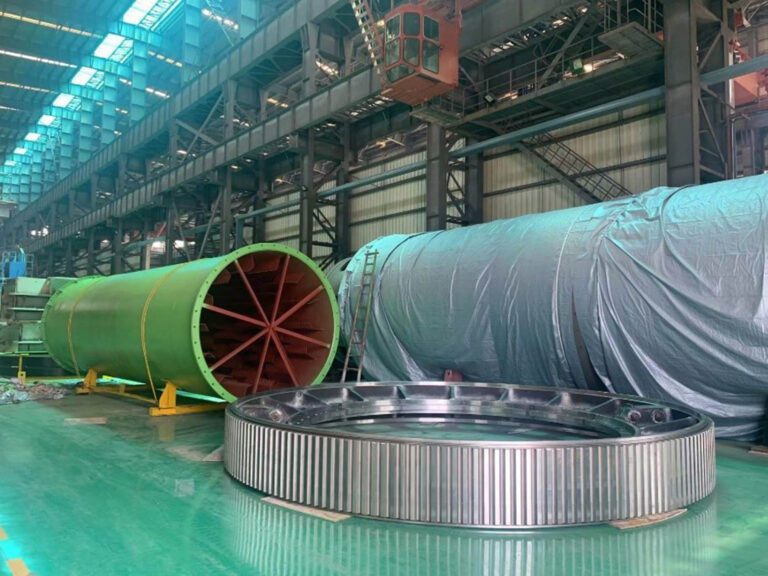

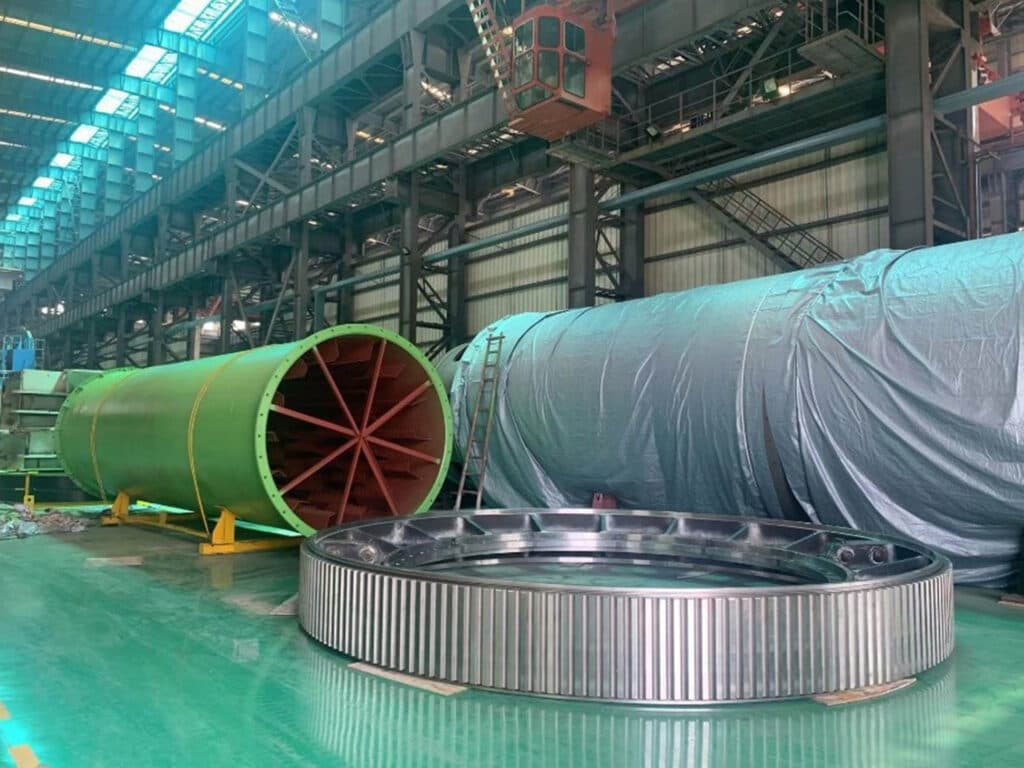

| Rotary Drum Coating machine | 30~40 | 2.2 x (8+1)m | 37kw | 1 |

| Raw material# 1 Map bucket elevator | 10~15 | TL400x 11m | 7.5kw | 1 |

| Raw material# 2 DAP bucket elevator | 10~15 | TL400x 11m | 7.5kw | 1 |

| Raw material# 3 15-15-15 bucket elevator | 10~15 | TL400x 11m | 7.5kw | 1 |

| Raw material# 4 16-40-0 bucket elevator | 10~15 | TL400x 11m | 7.5kw | 1 |

| DAP bucket elevator | 10~15 | TL400x 9.5m | 7.5kw | 1 |

| Final product bucket elevator | 10~15 | TL400x 9.5m | 7.5kw | 1 |

| Product Silo | 2150x2150x4100 | 8-15m3 | N/A | 1 |

| Belt Conveyor | 20-30t/h | B800x8m | 3kw | 1 |

| Bag filter | 30000m3/h | TL-4-2 | 7.5kw | 1 |

| Automatic Packer | 3000x3000x4000 | 1000bags/h | N/A | 1 |

| Automatic-palletizing machine | 8000x2200x3000 | 800~1000 bags/h | 15kw | 1 |

Raw materials for BB bulk blending fertilizer production line

Nitrogen fertilizer

The raw materials of BB fertilizer include urea, ammonium nitrate, ammonium sulfate, etc. The commonly used fertilizers are 28-6-6 high tower compound fertilizer and 26-11-11 high nitrogen content granular fertilizer. All raw material has to be granular form.

Phosphorus Fertilizer

Common phosphorus-containing raw materials for BB fertilizers include superphosphate(ssp), double superphosphat(dap)and monoammonium phosphate(mop); granular fertilizers with high phosphorus content such as 18-22-5 and 12-24-12 formula.

Potassium Fertilizer

Potassium chloride, potassium sulfate and potassium nitrate, as well as 25-10-16, 20-5-20 and other fully water-soluble compound fertilizer formulas.Or you can add some extruded granules of single-element fertilizers, such as irregularly extruded large granules of potassium chloride.

Other Additives

In order to make the fertilizer mix evenly, some fillers and conditioners are added to BB fertilizer, such as silicate, gypsum, lime, etc. These substances can adjust the particle size and physical properties of the fertilizer and prevent the fertilizer from agglomerating.

Micronutrients

In addition to the three major elements of nitrogen, phosphorus and potassium, some trace element fertilizers are often added to BB fertilizers, such as zinc sulfate, copper sulfate, manganese sulfate, magnesium sulfate, borax, etc. Although these trace elements are required in small quantities,

BB fertilizer Production Process

There are many raw materials for BB fertilizer, which are different from ordinary npk compound fertilizer production lines. Whether it is a high-tower compound fertilizer granulation line or a rotary drum granulation line, they all make powder into granules. The main principle of the BB fertilizer (also called blended fertilizer) production line is to mix various compound fertilizers with different formulas already made into granules in a certain proportion, and add some trace elements to achieve the desired effect. Therefore, the production of BB fertilizer is not to make powder into granules but to directly mix granular fertilizers of different formulas. For example, the 15-15-15 formula compound fertilizer granulated by rotary drum or the potassium sulfate and potassium chloride granular fertilizers granulated by extrusion are mixed to finally achieve the purpose of a scientific formula suitable for the local soil composition.

The second process of the BB fertilizer production line is the quantitative batching of raw materials. This step uses our high-precision electronic belt weighing scale(auto-batching system). On the production line, we are equipped with seven high-precision electronic batching belt scales, which can be used to mix seven different raw materials to make BB fertilizer. Because the raw materials of BB fertilizer are granular, there is no need to use a large bulk crusher or cage crusher for crushing, just mix them directly.

On this production line, we are equipped with a double belt scale. There are two types of belt scales, one is a single belt scale, the other is a double belt scale, and there is also a loss-in-weight scale. Considering the economic perspective, accuracy, and cost-effectiveness, we generally recommend customers use a double belt scale. The upper layer of the double belt scale is the feeding belt, and the lower layer is the weighing belt. The two scales are connected by a suspended weighing sensor. This not only improves the weighing accuracy but also makes maintenance more convenient. Compared with the other two scales, the double belt scale has a higher cost-effectiveness.

The third process of the BB fertilizer production line is the mixing of finished products. Since all the raw materials used in the BB fertilizer production line are finished compound fertilizers, whether they are granulated by high tower granulation line or drum granulation line, these compound fertilizers have been coated, so there will be no sticking. Generally speaking, when the raw materials are finished, they will enter the drum mixer. Depending on the output, the specifications of the mixer are also different. For example, the diameter of the mixer used in the BB fertilizer compound fertilizer production line with an annual output of 200,000 tons is about 830 mm. In the mixer, compound fertilizers of different formulas are mixed, and the fully mixed finished products enter the subsequent packaging section.

The coating process in this BB fertilizer compound fertilizer production line is optional. Why? Because if the raw materials you purchased contain some semi-finished products and you want to process them into finished products through this BB fertilizer production line, then the coating machine is essential. It can prevent the material from directly agglomerating and improve the strength of the particles. However, if the BB fertilizer raw materials you purchased are already finished products that have been coated, then there is no need to install a coating machine in the production line.

We have a customer in Africa who cannot guarantee that the raw materials he purchases every time are finished products that have been coated, and sometimes they may even be some semi-finished products. Therefore, he chose to install a coating machine at this location instead of a mixer. In this way, he can either purchase semi-finished raw materials for processing or directly use finished products for mixing.

If you want to change the color of compound fertilizer, such as blue, yellow or pink, you must use a coating machine. This color change effect cannot be achieved by simply using a mixer. If you plan to use a coating machine, you need the cooperation of a complete system. This system includes a screw conveyor for anti-caking agent, a dissolving tank for coating oil, and an oil injection pipeline, all of which are controlled by a DCS system.

The dust removal part in the BB fertilizer production line is optional. Why? Because BB fertilizer will produce a certain amount of dust in the process of mixing the finished product, but this dust has no effect on product quality or production process. If the owner has high requirements for dust removal in the workshop, or attaches great importance to environmental emissions and worker health, we recommend using a dust removal system consisting of bag dust collectors and centrifugal fans to handle dust in the entire BB fertilizer production line. We do not recommend the use of cyclone dust collectors in BB fertilizer production lines, because cyclone dust collectors are more suitable for handling dust containing more moisture, and require supporting gravity settling chambers and FRP chimneys, which occupy a large area. For this kind of pure dry BB fertilizer dust, bag dust collectors are obviously more suitable.

Regarding the finished product packaging machine of compound fertilizer, we provide two solutions: one is a semi-automatic packaging system and the other is a fully automatic packaging system. The traditional double-cylinder packaging scale has been eliminated, and now the main automatic quantitative packaging scale with servo motor is used. This servo motor packaging scale is faster and more accurate, and the packaging speed can reach 800 to 1,000 bags per hour. The scale body of the packaging scale is made of S304 stainless steel, with a thickness ranging from four to eight millimeters. The main electronic components are from Schneider, and the pneumatic components are imported from Japan. After the material comes out of the fertilizer coating machine, it first enters the buffer silo of the product packaging scale, and then passes through the automatic quantitative packaging below. The system is also equipped with automatic folding and automatic sewing systems to achieve semi-automatic packaging. If you have high requirements for automation, then the fully automatic packaging system will better match your needs. The difference lies in whether the automatic bagging machine is used in the bagging process. The automatic bagging machine can improve efficiency and save labor, but the investment cost is higher.

After the finished compound fertilizer is weighed and bagged by the packaging scale, it enters the palletizing system. This system is mainly realized by a fully stainless steel SS304 conveyor system, including the supporting legs. After the fertilizer bags are packed, they are transported bag by bag to the bottom of the palletizing robot machine for stacking. Usually we use ABB or Fanuc robot arms, with reliable quality steel trusses, and the speed is about 1000 to 1200 bags per hour. There are three types of palletizers. One is one machine with one rudder, which is the most common form; the other is one machine with two rudders, which is suitable for high production. Compound fertilizer production lines usually use single-grip palletizer systems, and double grippers are rarely used. In addition, the system is equipped with a conveying system and an automatic rewinding system. For companies that attach great importance to the modernization of the factory, our terminal machine is equipped with a pallet warehouse. This pallet warehouse makes the entire process fully automated, but the cost is also high. At the same time, the automatic pallet warehouse has very strict requirements on the material and shape of the pallet. Therefore, for companies with limited budgets, we do not recommend the terminal machine system with a pallet warehouse. On the contrary, if the requirements for automation are not high, you can choose our conventional wooden pallet system without the need for a pallet warehouse.

Bulk blending fertilizer Production Line Advantages

- The BB fertilizer mixing equipment production line uses a high-precision belt weighing scale to measure the ratio of raw materials, and the mixed fertilizer is evenly proportioned.

- The BB fertilizer mixing line has a small number of equipment, low investment cost, and very small floor space, which is suitable for compound fertilizer owners who are just starting their fertilizer business.

- The BB fertilizer production line can produce compound fertilizers of any formula, because she only buys finished products to mix, so she has a very large degree of freedom in terms of ingredients.

- The equipment manufacturing cycle of the BB fertilizer production line is short, and it can generally be completed in about a month. The installation time is also short, and basically does not require too much civil engineering.

Project Case 2024

- As of 2024, Tongli has established more than 100 BB fertilizer blending production lines worldwide. Including Tanzania, Kenya, Zambia…etc.

- The reasons why customers choose us include high-precision weighing system, efficient mixing system and fully automatic packaging system.

- Due to the diversity of formulas and flexibility of output, BB fertilizer blending production lines have become the first choice for compound fertilizer companies in many developed countries.