Automatic Packing Machine

Automatic Packing Machine

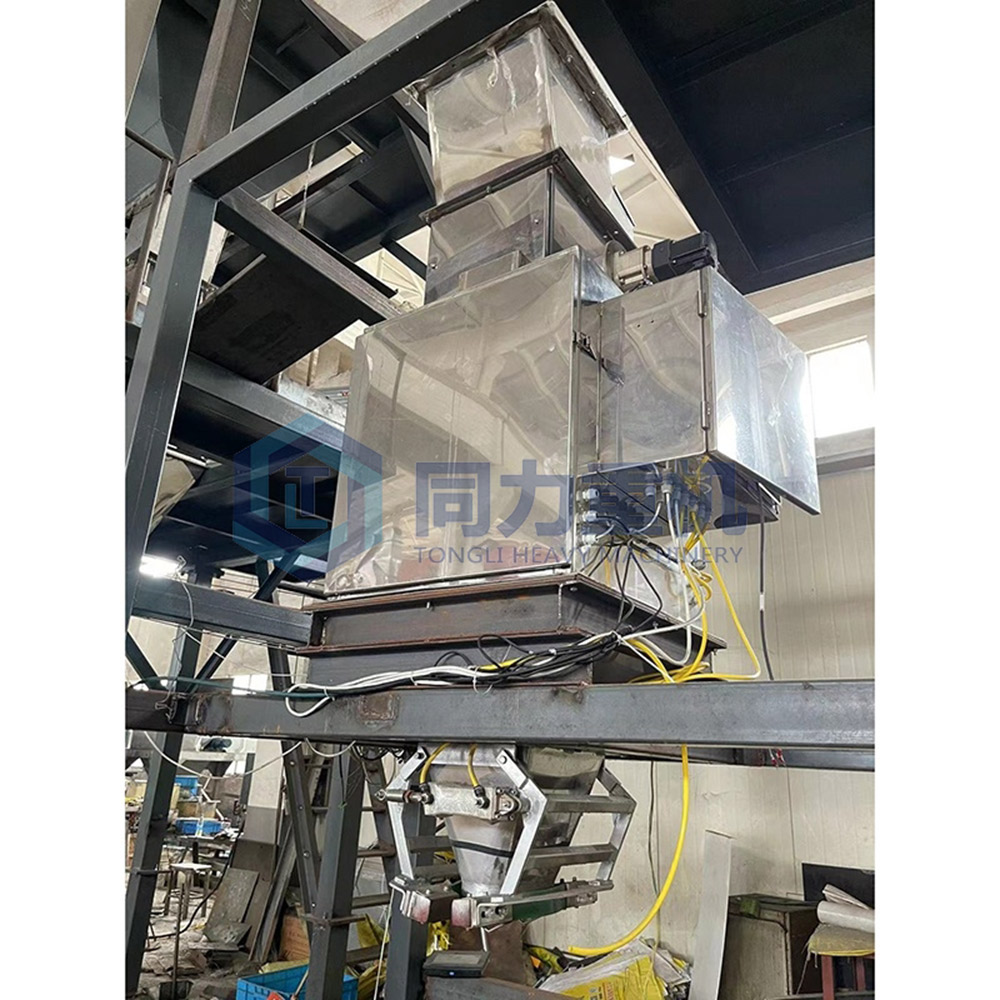

Automatic packing machine is an electronic scale for automatic quantitative weighing of bulk materials. TONGLI automatic quantitative packaging system is composed of automatic quantitative packaging scale, sewing machine, folding machine, sewing conveyor and controlled by PLC touch screen.

Compared with other manufacturers, TONGLI uses a servo motor to control the feeding mechanism, with higher weighing accuracy and faster speed, and the overall use of SS304 stainless steel. The automatic quantitative packaging scale is connected with a folding machine and a bag sewing machine to realize automatic folding and automatic bag sewing, reduce labor and improve work efficiency.

Weighing Speed: max 1200bags/h 20-50kg.

Advantages of Fertilizer Automatic Packing Machine

PLC controlled, equipped with SS304 on-site control cabinet.

Main components of bag sewing machine, edge folding machine and bag sewing conveyor :SS304 stainless steel.

The material of the automatic packaging scale is all SS304 stainless steel.

The automatic quantitative packaging scale is fed by the servo motor control, the measurement accuracy is higher than the traditional cylinder packaging scale, and the efficiency is higher.

Automatic Packing Machine Applicable materials

Agricultural production

Automatic packaging machine can be used in agricultural production of various fertilizers and pesticides dosage operation.

Pharmaceutical industry

automatic packaging machine can be used in the pharmaceutical process of various raw materials dosage operation, such as powder, liquid, etc..

Food processing industry

automatic packaging machine can be used in food processing process of various packaging operations, such as seasoning, dough, feed, etc..

Design principles of compound Automatic Packing Machine

The automatic packing machine is composed of load cell, weighing instrument, weighing transmitter, and the mechanical actions required for the process are controlled by programmable controller PLC, and the mechanical design, machining, sheet metal process, surface treatment and other technologies are reasonably applied to make the execution elements and control system work together to form a perfect combination. The folding machine, sewing machine and sewing conveyor can effectively control the speed of the finished products passing through the PLC interlocking to realize efficient sewing.

Equipment parameters

| Parameter | Value | Unit |

|---|---|---|

| Weighing Range | 5-50 | KG |

| Graduation Value | 0.035 | oz |

| Weighing Accuracy | 0.002 | |

| Weighing Speed | 440-660 | b/h |

| Working Environment Humidity | ≤90% | |

| Power Supply | 380V 50Hz | |

| Air Pressure | 5.8-11.6 | psi |

What Else Does TONGLI offer?

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas

The only place where you’ll get the perfect solution for fertilizer industry needs.

Frequently Asked Questions

1. Installation: After the machine arrives at the factory, it will be installed in conjunction with the process, indicating the elevation and horizontal position, tilted installation, generally tilted at 2-5 degrees (which can be adjusted to make the user’s needs), and the machine bracket and transmission frame even ground angle holes, which can be mounted on rolled condensed soil.

① machinery each base and the foundation between the pad into the deed-shaped mat board thickness should not be greater than 30-35mm;

② the height of the base with the deed-shaped pad to adjust the height of the base to make the base 5 degrees of inclination;

③ After each base is adjusted properly, put the cylinder on the support and adjust the carrier wheel;

④ Install the drive part of the film wrapping machine;

⑤ Be sure that the bracket wheel, transmission device and cylinder are properly adjusted and start pouring cement, and after 8-10 days, start the no-load test run after the cement is solidified;

⑥ Method of adjusting the position of the machine body:

a. On the full length of the left and right sides of the machine body, install two parallel steel wires with a diameter of 0.5-1mm and check the level of the wires with a level meter;

b.Lower two phase hammers tangent to the rolling circle from each rolling circle down the sides of the dryer;

c.Measure the distance from the steel wire to the wire drop to detect the body in the horizontal position;

d. Measure the relative vertical elevation of the two rolling circles to check the position of the machine body in the vertical plane;

e. Use the method of moving the electric torque wheel to adjust the measurement of the two articles c and d, so that the machine body is in the correct position;

2. No-load test run:

1). Uninterrupted no-load for 8 hours, the temperature of each bearing should rise smoothly, and the temperature of the bearing should not be higher than 50 degrees Celsius at the termination of the test run;

2). The noise of gears should be average and should not be high or low;

3). After the test run, the bearings shall be observed without serious wear and abrasion.

A.Starting the machine

1. The following preparations should be made before starting the film wrapping machine;

a. Check and adjust the powder feeding device and protection equipment;

b. All bearings and lubricating devices of friction surfaces should have appropriate quantity of grease;

2. It is forbidden to start the film wrapping machine without checking the film wrapping machine and auxiliary mechanical equipment;

3. The steps to start the film wrapping machine are as follows:

a. Start the motor of the film wrapping machine.

b. Start the feeding and discharging conveying equipment.

B. Stopping

1. The steps to stop the film wrapper are as follows:

A. Stop adding raw material to the wrapper;

B. Turn off the drive motor of the wrapping machine;

C. Stop the equipment for transporting granular materials;

1. Dry grease should be smeared at the gears before starting the machine;

2. Dry grease to be smeared on the surface of rolling belt once in 7 days;

3. Bearing housing to be hit or renewed with new dry grease every three months;

4. Add gear oil once before the reducer is used and replace it every four months thereafter;

Pinion gear is worn, install pinion gear upside down, if both sides are worn, new gear is needed.

The intermediate connection between the large gear and the cylinder is damaged, adjust the connection and make appropriate treatment if necessary.

Clamping roller belt to the side of a concave joint

Clamp the belt to the concave joints with pads or wedges, but beware of over-clamping, which can lead to accidents, but uneven tensioning can cause the machine to jump and vibrate.

Wheel wear Refurbish or replace the wheel according to the degree of wear

Block wheel wear Repair, move, or replace with new block wheel depending on degree of wear

Simple body vibration