Crusher Tongli

The crusher is mainly used in the production line of bio-organic fertilizer, it is the ideal equipment for crushing many kinds of fertilizer raw materials, such as straw, fish meal, sludge amino acid and cereals.

Crusher

Tongli’s crusher is including DAP crusher/ Double cage crusher/ Chain mill/ Ton bag crusher that crushes green waste, food waste, biomass waste, animal manure and abattoir waste for the production of compost and organic fertilizers and minimizes fines and lumps or gypsum in the crusher.

Crusher Pros

- Increased efficiency and productivity: Uniform granulation is achieved, improving the quality and effectiveness of fertilizers while shortening processing time.

- Scalable: Scalable to accommodate both small and large-scale operations, providing flexibility for business growth.

- Operator Friendly: Modern crushers have automated features that simplify operations and reduce the need for skilled labor.

- Customizable Settings: Adjustable settings allow the crushing process to be customized to specific material requirements.

- Handles a wide variety of materials: Can pulverize a wide range of materials including organic and inorganic compounds.

- Reduced Maintenance Costs: Advanced design reduces wear and tear, lowering maintenance frequency and costs.

- Cost savings: minimize waste by efficiently converting raw materials into usable form.

The Main Structure Of Fertilizer Crusher

The main structure of the crusher in the fertilizer plant consists of an inlet/outlet/crushing chamber/frame/automatic control system, which crushes the raw material through the internal rotor, hammers or blades, and the impact plate to achieve semi-finished products that can be made into fertilizers.

Crusher Products

DAP Crusher

Double Cage Crusher

Chainmill Crusher

Ton Bag Crusher

Fertilizer Rotary Drum Cooler Applications

How TONGLI process order?

Contact Via Email

Find our contact information via email or whatsapp

Sales Representative

Our experienced expert will get in contact with you

Fill out a quick questionnaire

For details of raw material and site condition so on

Making Proposal

Making customized fertilizer industry solution

Fabrication

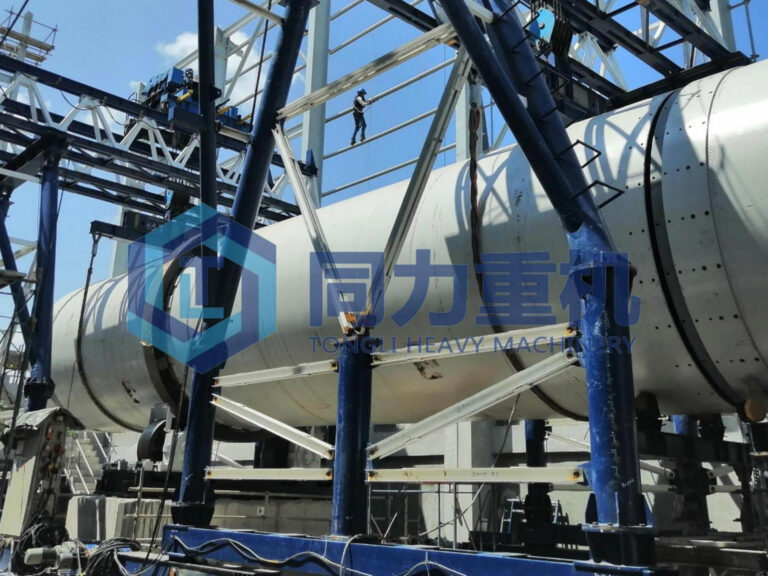

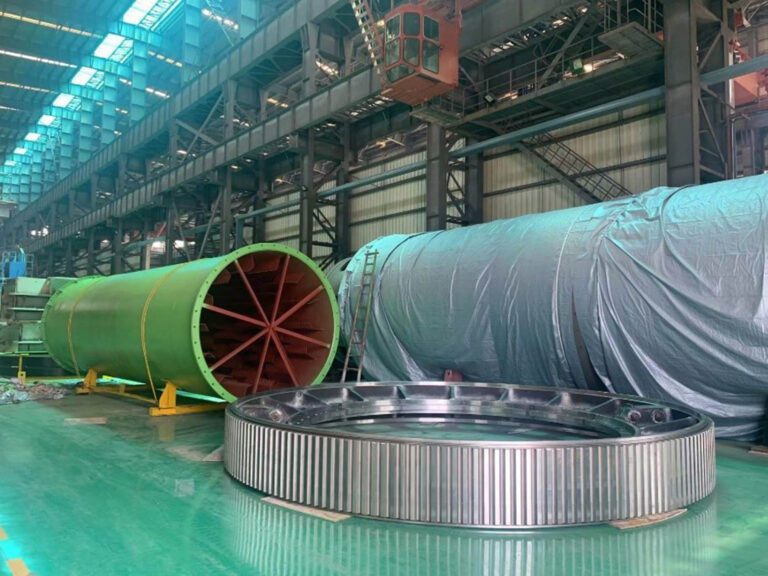

Start manufacturing after everything are checked

Commission

Send our most experienced installation engineer

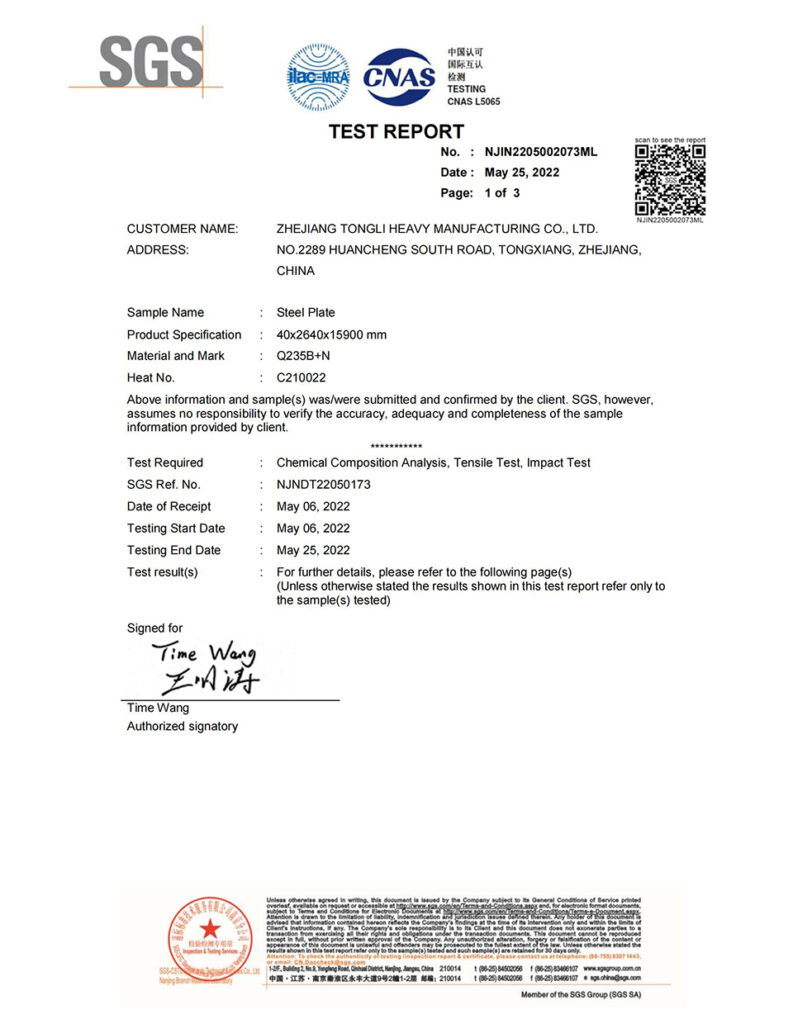

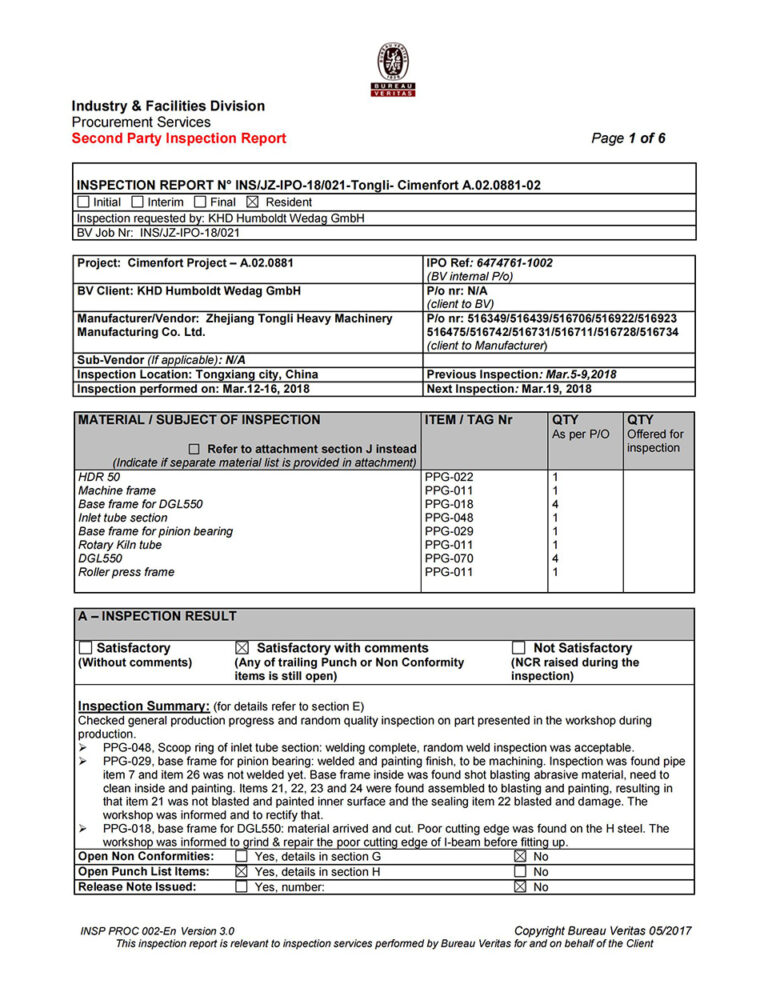

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas