Granulator

What is a TONGLI npk compound fertilizer steam drum granulator?

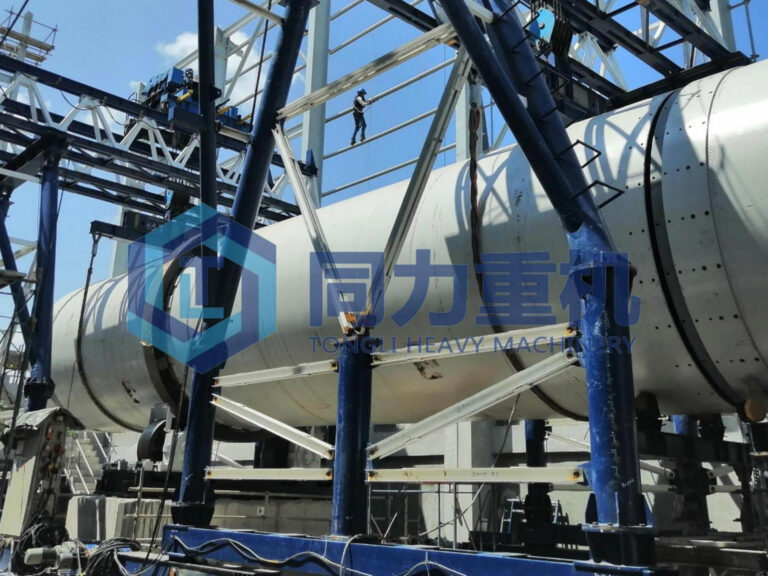

The TONGLI rotary drum granulator is one of the key equipments in the npk compound fertilizer industry and is suitable for cold and hot granulation as well as the large-scale production of high, medium and low concentration compound fertilizers. The fertilizer making machine main working method is called pellet wet granulation. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted after the humidity is adjusted in the granulator shell. Under certain liquid phase conditions, with the help of the rotation of the drum cylinder, the material particles are agglomerated to form small granule.

What are the type of fertilizer can be produced by using steam drum granulation method?

- NPK compound fertilizer is a type of fertilizer that contains three essential nutrients required for plant growth: nitrogen (N), phosphorus (P), and potassium (K).

- Organic fertilizer is a type of fertilizer derived from natural sources, such as plant or animal matter, minerals, or microbes.

- Organic-inorganic fertilizers, sometimes referred to as blended or compound fertilizers, are fertilizers that contain both organic and inorganic components. These fertilizers are designed to provide plants with a balanced mix of nutrients from both organic and synthetic sources.

What are the Key components of a compound fertilizer rotary granulator?

A rotary granulator shell is a key component of a rotary granulator machine.cylindrical outer structure of the machine where the granulation process takes place. It houses the internal components responsible for granulating the materials fed into the machine. The shell is designed to withstand the mechanical stresses and operating conditions encountered during the granulation process.

- High-quality standard materials.

- ASME international certified welder.

- SGS certified third party quality inspection staff.

- Heat treating and sandblasting surface treatment.

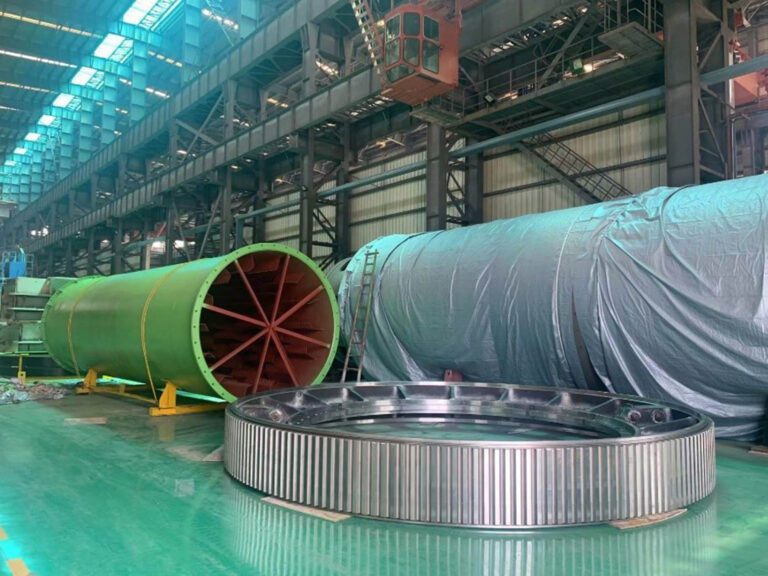

How to select rotary drum granulator Girth Gear?

a rotary granulator girth gear plays a vital role in transmitting torque from the pinion to the granulator drum, enabling the granulation process in various industrial applications. Its features include high strength, large diameter, precision machining, and alignment requirements to ensure efficient and reliable operation.

- TONGLI has Its own foundry, others don’t.

- TONGLI use high standard metal material.

- TONGLI use Germany spectrometer to control composition of molten metal.

- TONGLI three-phase electric arc furnace ensure casting quality.

What is the Riding Ring of a fertilizer granulator?

a rotary granulator riding ring is typically made of durable materials such as cast steel or forged steel. It is designed to withstand the weight of the rotating drum and the materials being processed within the granulator.

- TONGLI has Its own foundry, others don’t.

- TONGLI use high standard metal material.

- TONGLI use Germany spectrometer to control composition of molten metal.

- TONGLI use Alkali phenolic resin sand and three-phase electric arc furnace ensure casting quality.

Key component: Driving Unit, Supporting roller and thrust roller system

a rotary granulator supporting roller is a component designed to provide support and stability to the rotating parts of the granulator machine, it is mainly composed of the base frame, bearing housing, bearing, forged shaft, metal casting roller, thrust roller and position adjustment screw.

- High quality-all metal casting and welding are heat treated and Magnetic testing performed.

- All metal castings are UT ultrasonic tesed and no defect and is produced by our own.

- State-of-art design, with 65+ years of experience we have our own know-how in terms of manufacturing and design.

What is granulator Key component Hood Cover?

a rotary granulator hood cover is a protective casing that encloses the rotary granulator machine, The hood cover helps to contain the granulation process within a closed environment, preventing the dispersion of dust, particles, or vapors into the surrounding area. This containment is crucial for maintaining a clean and safe working environment, as well as for complying with regulatory standards related to air quality and occupational health and safety.

- High quality-Material.

- Advanced manufacturing process.

- Dedusting concern intergrated design.

What is the working principle and adventages of a rotary drum granulator?

Steam, gaseous ammonia, or phosphoric acid, nitrogen solution, phosphorus ammonia slurry, heavy calcium slurry, etc. are introduced into the drum granulator to complete the chemical reaction in the drum. Through the rotation of the drum, the material in the drum changes in humidity and The powder is agglomerated into particles under the action of temperature. Adventages of Steam-drum granulation method:

- Adapt to a variety of fertilizer formulas.

- High agglomeration rate can reach 70%.

- High drying efficiency, steam-heating.

- High quality rubber lining and SS304 Pressbar.

TONGLI NPK compound fertilizer granulator specification:

- ZJTL Series

- Diameter(mm)

- Length(mm)

- Capacity(t/h)

- Power(KW)

- ZJTL 2.0x10m

- 2000

- 10000

- 16

- 30

- ZJTL 2.2x10m

- 2200

- 10000

- 20

- 37

- ZJTL 2.5x10m

- 2500

- 10000

- 26

- 55

- ZJTL 3.0x8.0m

- 3000

- 8000

- 45

- 132

- ZJTL 3.2x9m

- 3200

- 9000

- 50

- 160

- ZJTL 3.5x9.0m

- 3500

- 9000

- 56

- 200

- ZJTL 4.0x10m

- 4000

- 10000

- 65

- 280

How TONGLI process order?

Contact Via Email

Find our contact information via email or whatsapp

Sales Representative

Our experienced expert will get in contact with you

Fill out a quick questionnaire

For details of raw material and site condition so on

Making Proposal

Making customized fertilizer industry solution

Fabrication

Start manufacturing after everything are checked

Commission

Send our most experienced installation engineer

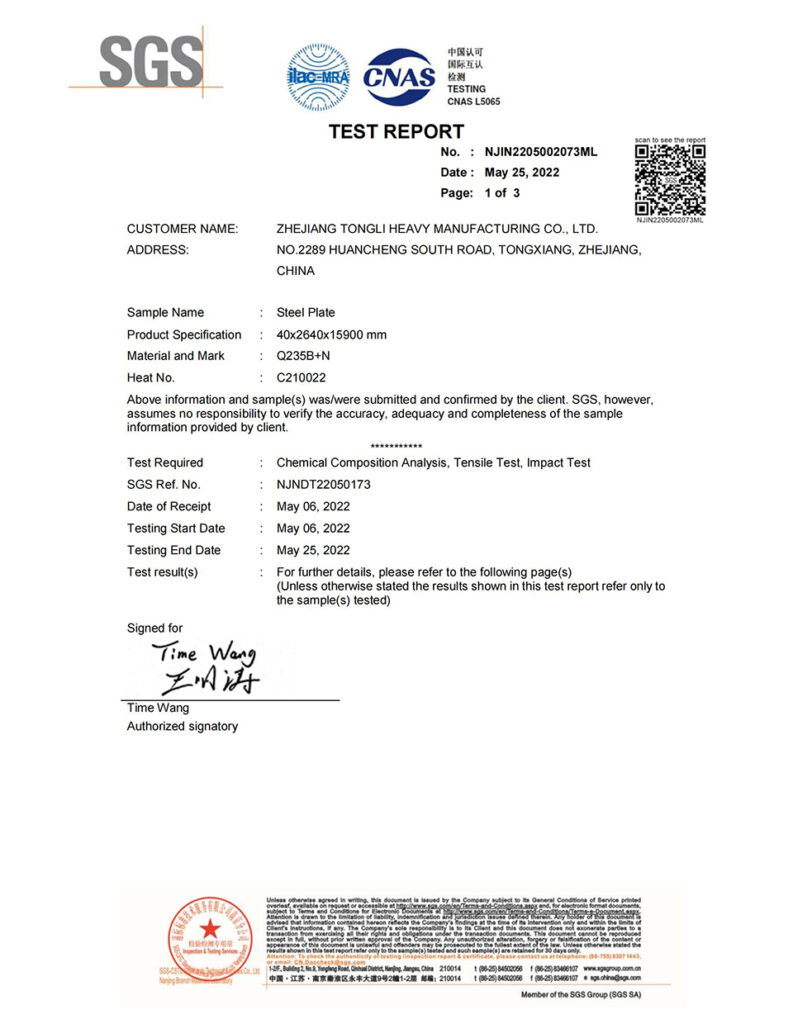

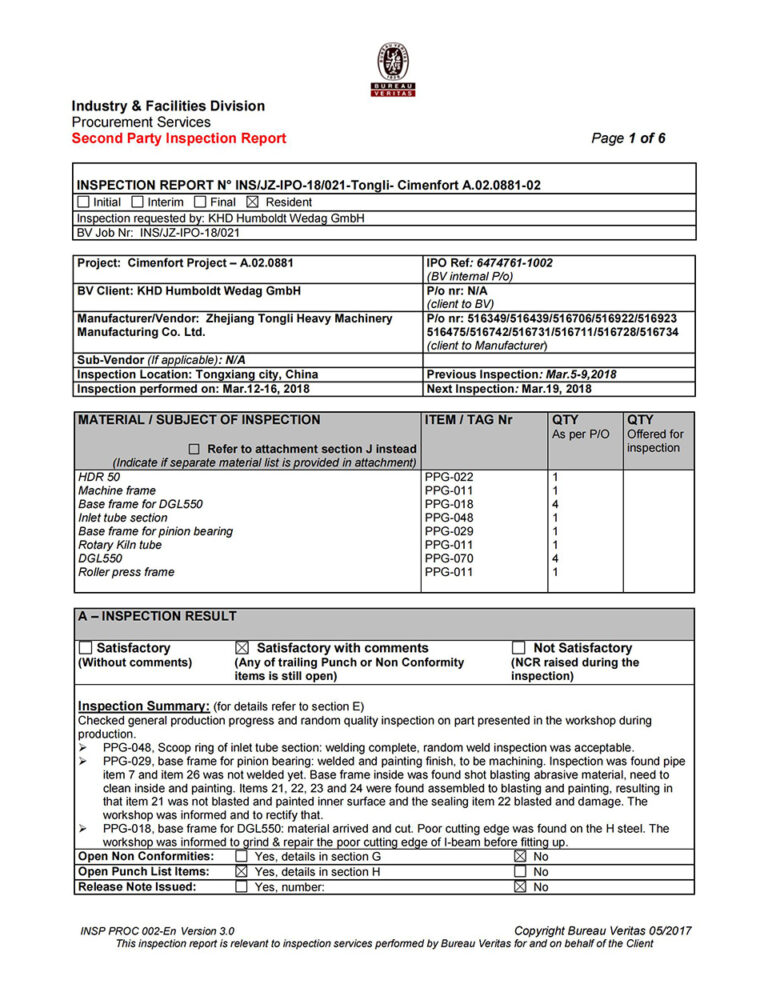

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas