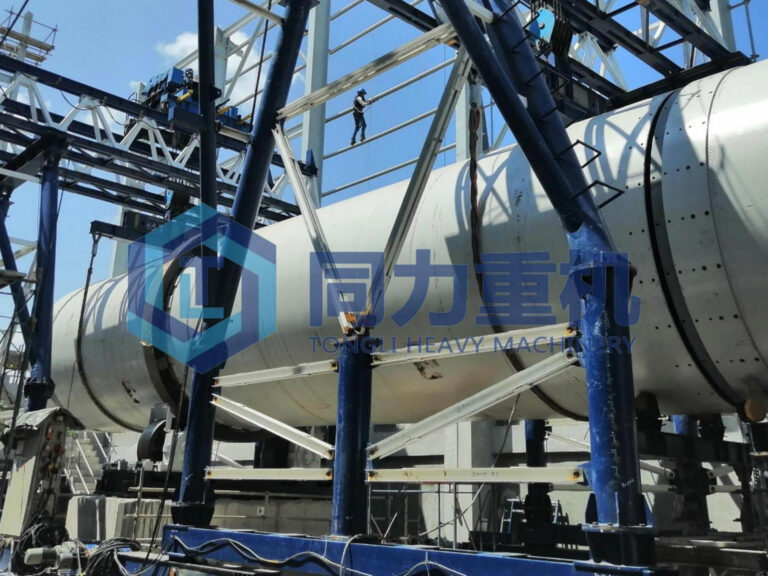

Hot Air Generator

The Hot Air Generator (HAG) is ideal for the fertilizer industry because of its rugged design, providing you with the heat you need consistently and in a safe manner!

Introduction To Hot Air Generator

Tongli’s Coal / Oil / Gas / Biomass Hot Air Generators are known for their high efficiency and minimum maintenance. These hot air generators based on fluidized bed combustion are available in two designs, vertical and horizontal. Our hot air generators are very economical and can be operated with low cost locally available fuels. It can be operated in a wide temperature range according to the process requirements. With the energy capacity suitable for the application, it can be successfully used in different fields such as soil industry, air-conditioning industry, fertilizer industry, sugar industry, paper industry, metal industry, drying ovens, cement industry and so on.

Features of Hot Air Generator Machine

- Use of gas, heavy oil, light oil, and dual fuel burners

- Direct, indirect, and brick designs according to process requirements.

- In direct hot air generators, combustion gases and air are mixed directly in the mixing chamber without any heat transfer medium, thus minimizing heat transfer losses and increasing thermal efficiency.

- Designing brick or brickless combustion chambers, depending on the process, thermal capacity, and outlet temperature.

- In brick hot air generators, the refractory bricks covering the combustion chamber and the heating through the air surrounding the combustion chamber resist high temperatures and temperature stresses.

- Brickless hot air generators are designed to resist high temperatures and temperature stresses with combustion chambers made of chrome-nickel material and by heating the air mixture around the combustion chamber.

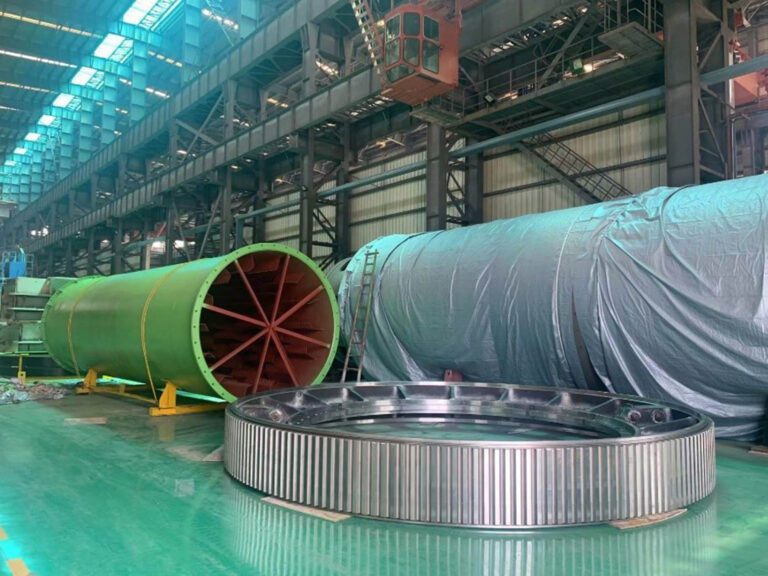

Hot Air Generator Products

Coal-fired hot air generator

Natural gas-fired hot air generator

Diesel-fired hot air generator

Biomass-fired hot air generator

Fertilizer Conveyor Systems Applications

What Else Does TONGLI offer?

How TONGLI process order?

Contact Via Email

Find our contact information via email or whatsapp

Sales Representative

Our experienced expert will get in contact with you

Fill out a quick questionnaire

For details of raw material and site condition so on

Making Proposal

Making customized fertilizer industry solution

Fabrication

Start manufacturing after everything are checked

Commission

Send our most experienced installation engineer

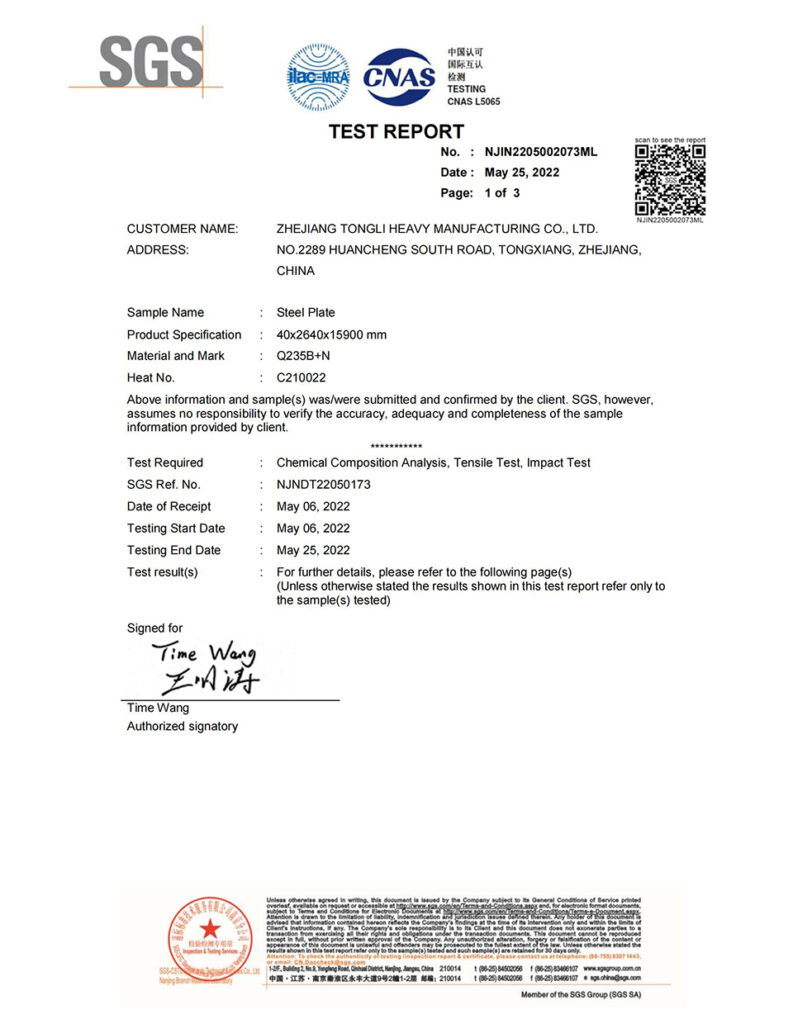

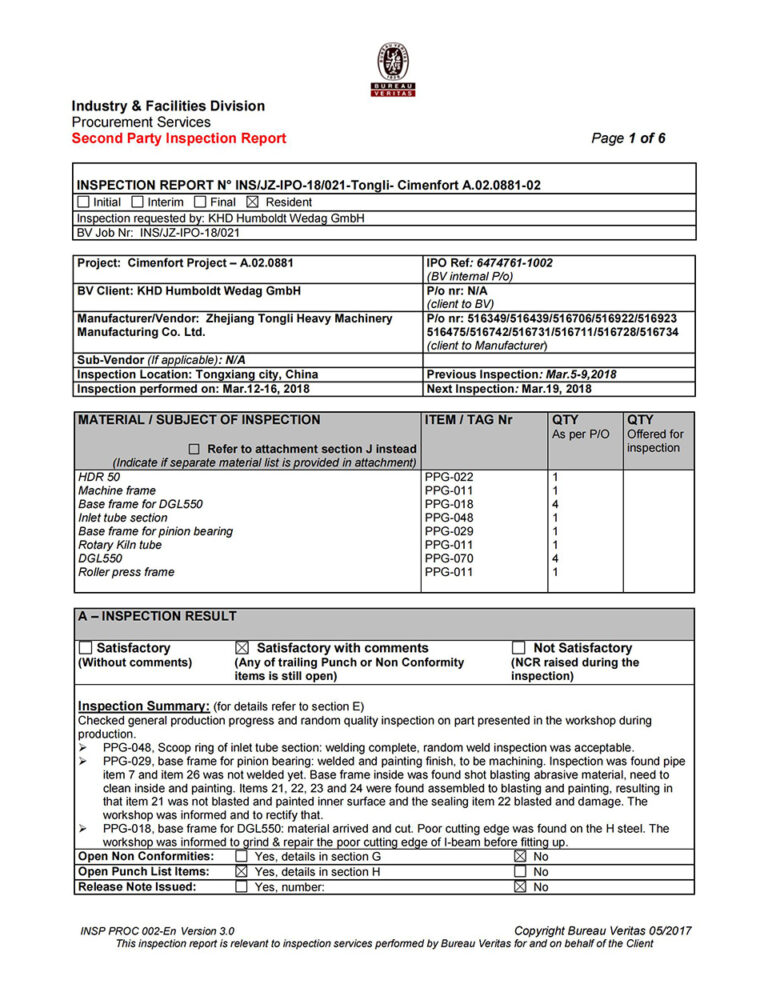

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas