No.1 NPK fertilizer plant Manufacturer

World's Leading Fertilizer Equipment Industry Corporation

NPK compound fertilizer production line

Tongli steam granulation NPK compound fertilizer production line typically involves raw material preparation, steam granulation, drying, cooling, screening, coating, and packaging. Raw materials are mixed and then subjected to high-pressure steam to form granules. This process ensures uniform distribution of nutrients and improves the physical properties of the fertilizer, such as granule size and strength, ultimately enhancing its effectiveness in agricultural applications.

Double roller extrusion npk fertilizer production line

A Tongli double roller extrusion NPK compound fertilizer production line is a system designed for the manufacturing of NPK compound fertilizers through a specialized extrusion process. This process involves blending raw materials such as urea, ammonium phosphate, and potassium chloride in predetermined ratios, then subjecting the mixture to high pressure and temperature within the extruder to form granules.

High tower prilling npk fertilizer production line

Tongli high tower prilling NPK compound fertilizer production line designed for the manufacturing of complex fertilizers containing high nitrogen content, phosphorus, and potassium in precise proportions. The process typically involves raw material preparation, blending, granulation, drying, cooling, and packaging. The “high tower” aspect refers to the vertical design of the equipment, which allows for efficient heat transfer and optimal control over particle size and distribution during prilling, a method of forming small spherical pellets. This production line is capable of producing high-quality NPK fertilizers with tailored nutrient compositions.

Organic-inorganic npk fertilizer production line

An organic-inorganic NPK compound fertilizer production line combine both organic and inorganic components to provide a balanced blend of essential nutrients for plant growth. It consists of various stages including raw material preparation, mixing, granulation, drying, cooling, screening, coating, and packaging. Organic materials such as compost, manure, or plant residues are combined with inorganic substances like nitrogen (N), phosphorus (P), and potassium (K) to create a fertilizer with enhanced nutrient content and improved soil fertility.

What Does TONGLI offer?

Who is TONGLI ?

Starting from 1958

Zhejiang Tongli Heavy Machienry Co., LTD established in year 1958 is by far the largest and earliest npk compound fertilizer production line equipment manufacturer in China.

Committed to providing high-quality compound fertilizer production equipment for global customers

———–TONGLI

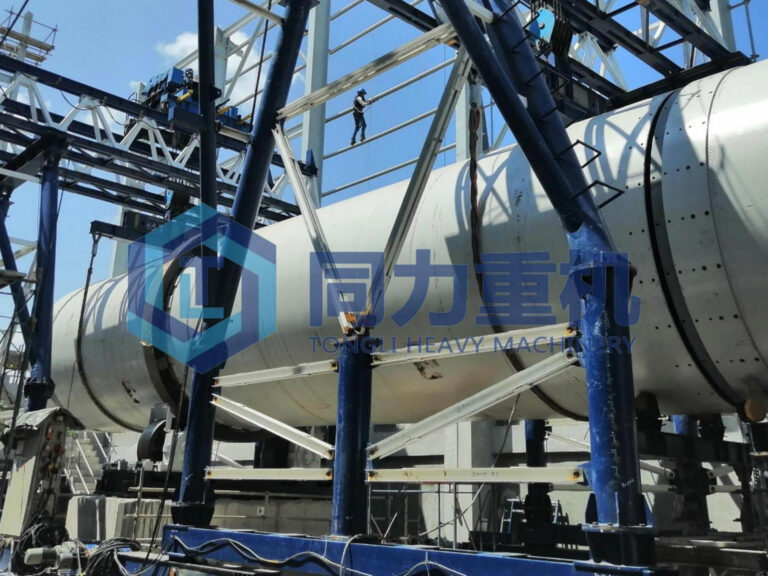

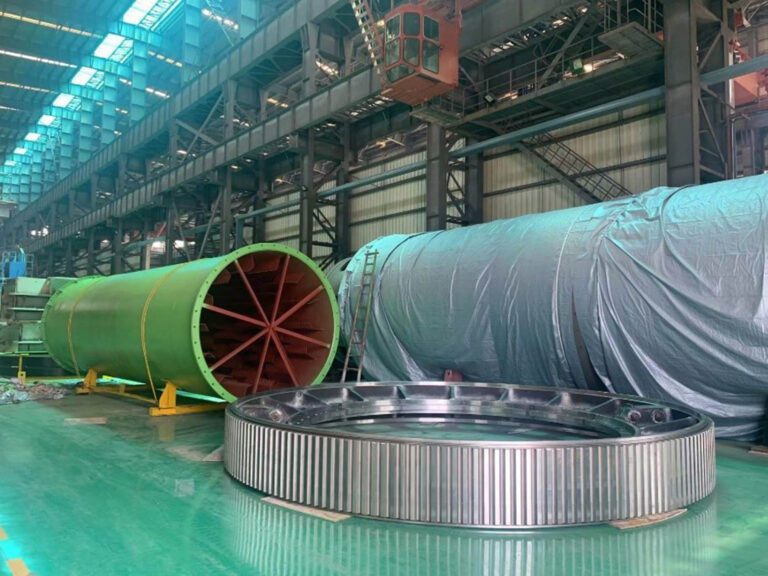

TONGLI Factory

Who work with TONGLI ?

BASF

Yara

Mosaic

Thyssenkrupp

GE Group

CNCEC

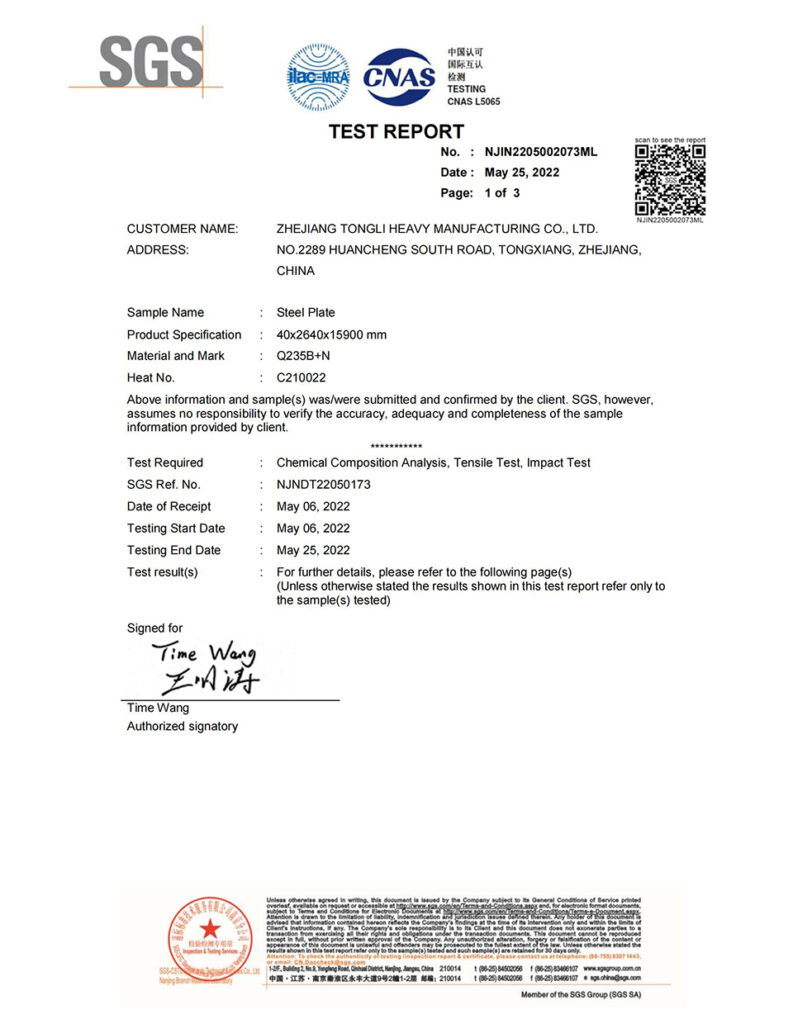

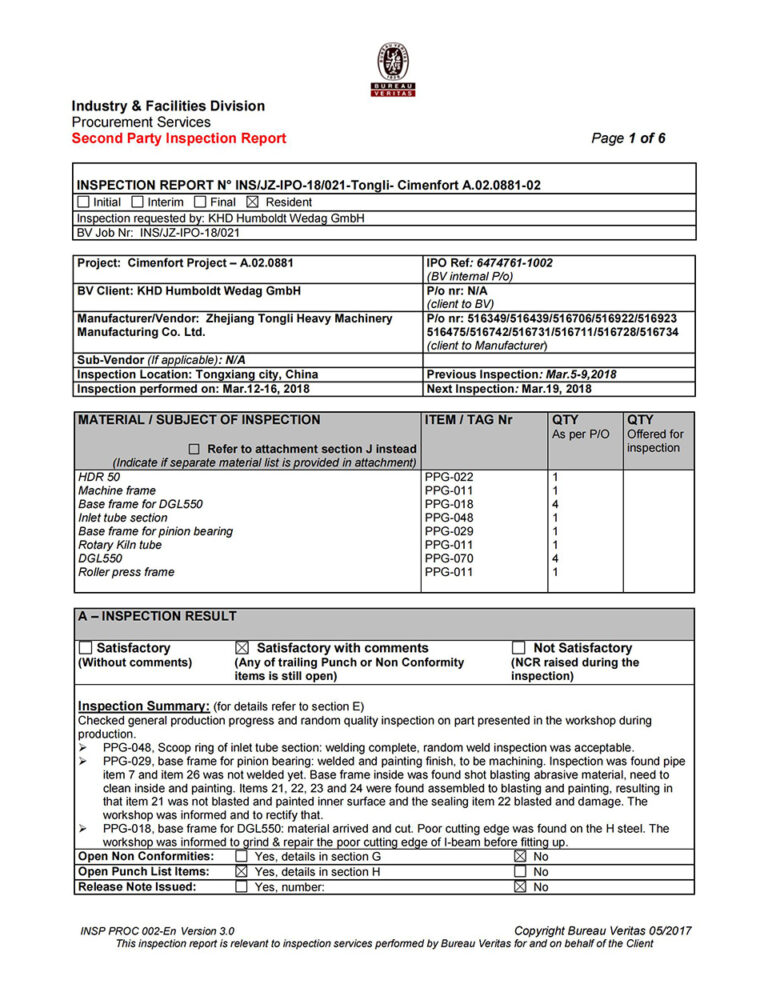

TONGLI Certification

Intertek

SGS

Bureau Veritas

Why Choose TONGLI ?

We found many manufacturers for quotations, and Tongli's price was the highest. However, after visiting Tongli's factory and their project cases, I finally chose Tongli. The design concept of the entire production line is completely different from other companies, and the manufacturing capabilities and production The craftsmanship completely surpasses all other manufacturers

Private Owner Africa

Our company's first production line was purchased from Henan, China. They provided a lifetime warranty, but the entire line was scrapped and could not continue to operate within 1 year. After many investigations, we finally found zhejiang tongli, the largest compound fertilizer equipment manufacturer in China. The quality of the equipment provided by tongli is completely superior to that provided by other manufacturers.

Procurement Manager Africa

Our company has purchased 4 lines from tongli. The material selection, design concept and manufacturing level of tongli equipment are unquestionable. However, as an old customer, I would recommand tongli use more carbon steel on the equipment instead of SS304, so that the total price can be cheaper.

Pupuk Urea Procurement Indonesia

If you need high-quality products and reliable production lines, tongli will be the first choice. If there are no requirements for quality, there are enough manufacturers on the market to give very, very low prices. The only reason why I chose tongli is that they are very responsible and trustworthy. They will not raise the price after signing the contract. Believe or not, many manufacturers in henan who start with very low prices will do this.

Private Business owner Mid-East Asia

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas

The only place where you’ll get the perfect solution for fertilizer industry needs.

Stay informed on our latest News

Tongli Fertilizer Equipment has shipped to Tanzania.

In April 2023 TONGLI 2x200,000t NPK compound fertilizer production line is loading at the Shanghai port and will be send to dar es salaam port in Tanzania...

Tongli fertilizer dryer installing at the site.

Today let us take a walk into one of TONGLI's project in indonisia, Tongli NPK compound fertilizer dryer is installing with our on-site engineer...

Tongli fertilizer dryer installing at the site.

Today we are visiting one of TONGLI's domestic project for AYZS fertilizer group limited, the capacity is 150,000 tons per year steam drum granulation...

Where we at ?

TONGLI Location

N0. 2289 huancheng south road tongxiang, jiaxing, zhejiang, China