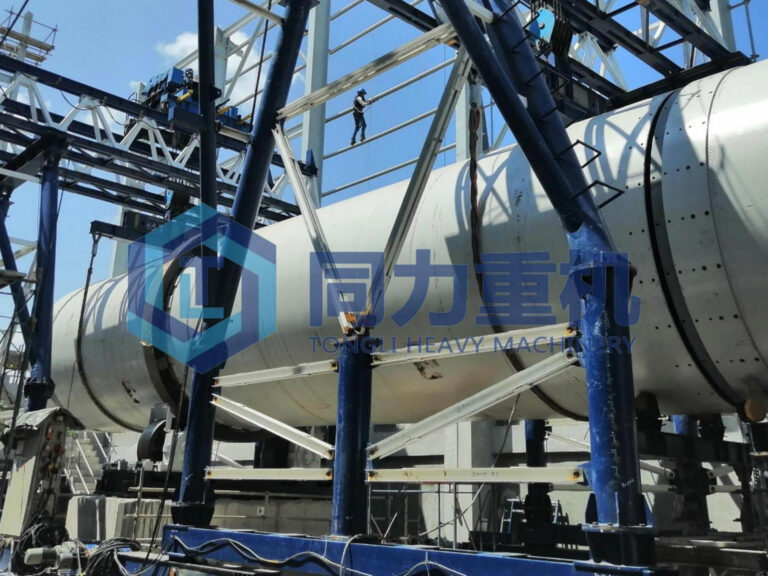

Rotary Drum Granulator

Rotary Drum Fertilizer Granulator

Rotary drum fertilizer granulator is one of the key equipments in fertilizer production industry, which is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizer. Its main working mode is aggregate wet granulation. Through a certain amount of water or steam, the base fertilizer is humidified in the cylinder body and fully undergoes chemical reaction. Under certain liquid phase conditions, with the rotary movement of the cylinder, the material particles are extruded and agglomerated into particles.

Difference Between Rotary Drum Fertilizer granulators And Other Granulators

High production capacity

Rotary drum granulators can produce large quantities of fertilizer granules at a relatively low cost.

Can handle a wide range of materials

Rotary drum granulators can be used to granulate a wide variety of fertilizer materials, including both organic and inorganic fertilizers.

Produces strong, durable granules

The granules produced by rotary drum granulators are typically strong and durable, which makes them easy to transport and store.

Advantages of Briquette Granulator

Briquette Granulator Applicable materials

Compound fertilizer

Rotary drum fertilizer granulators are commonly used to produce compound fertilizers, which are mixtures of two or more nutrients.

View ServiceOrganic fertilizer

Rotary drum fertilizer granulators can also be used to produce organic fertilizers, which are made from natural materials such as manure, compost, and plant residues.

View Servicefood industry

Rotary drum fertilizer granulators can be used to produce animal feed pellets.

View Service

Compound fertilizer rotary granulator design principle

- Counter flow: Tongli compound fertilizer granulator adopts counter flow arrangement design, which improves heat transfer efficiency and reduces energy consumption.

Gradual heating: Gradual heating is essential to avoid thermal shock and to facilitate the complex chemical reaction that converts raw materials into cement clinker. - Binder Delivery System: An appropriate binder delivery system should be designed to accurately control the amount and dosage of binder. This may involve pumps, nozzles, atomizers, and other components to distribute the liquid evenly over the material.

- Spraying Mechanism: A granulating liquid, such as a binder or solution, is sprayed onto the material as it tumbles through the drum.

- Material flow and residence time: The residence time of the material in the drum affects the size and quality of the particles without excessive agglomeration or over-granulation.

- Drum design: Optimized mixing, blending and tumbling of the material to ensure uniform distribution of the granulating liquid and consistent particle formation.

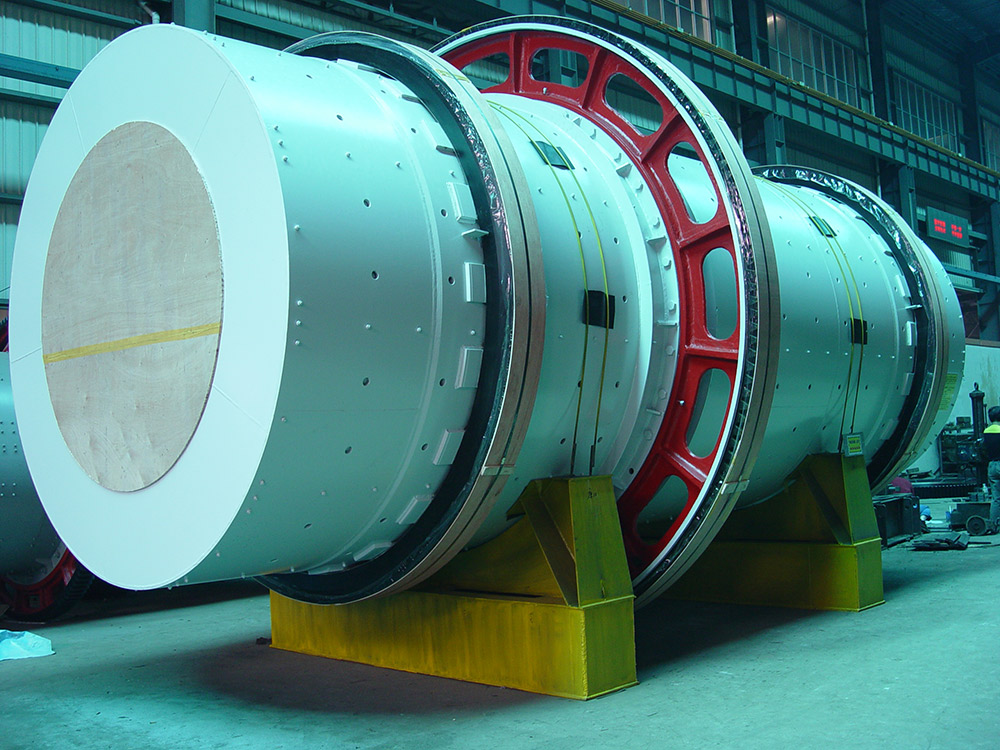

Compound fertilizer granulator structure

The structure of compound fertilizer granulator varies according to the specific design, generally consists of the following parts: bracket, large gear, support device, pinion, cover, gear cover, shell, transmission device and so on.

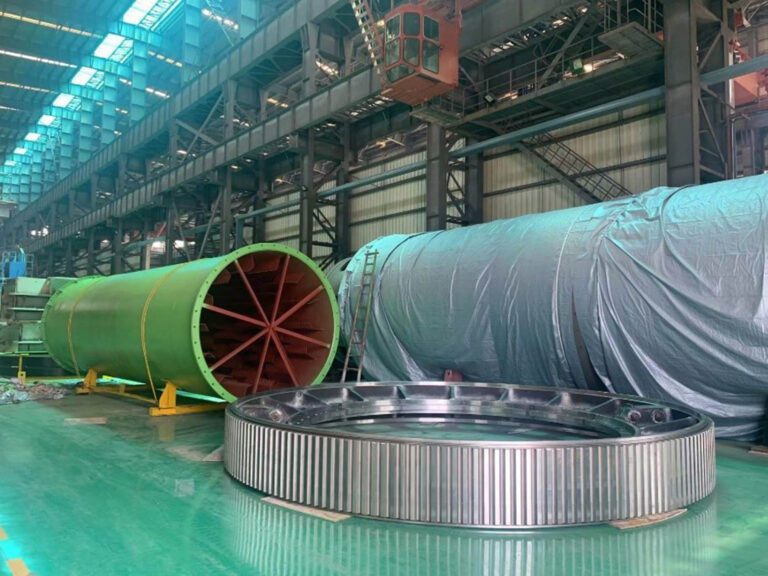

Pelletizer Shell

A thick steel cylindrical structure that provides the necessary strength and rigidity to withstand the high temperature environment inside the pelletizer. It is also used as a container for materials and gases in the cement manufacturing process. tongli granulator shells have excellent sealing properties, with smooth machined edges on each shell to enhance sealing and service life of the rotating drum.

Support Rings (Tires)

The compost granulator shell is supported by multiple support rings, usually 2, which are secured to the shell by internal spot welded pads. This allows the granulator to rotate smoothly along its axis and helps to distribute the weight of the granulator.

Toothed ring

Composite fertilizer granulator toothed ring is a large toothed ring around the granulator, together constitute the main driving device of the granulator rotation.

Support Device

composed of support rollers and thrust rollers, the shaft is forged to extend the service life of the compound fertilizer granulator. All metal-casting support rollers and metal casting thrust rollers are machined and heat-treated for reliable performance.

Rotary Granulator Pinion

The pinion is responsible for transmitting rotary motion and torque from the drive mechanism to the compound fertilizer granulator itself.

Thrust Roller

Supports the weight of the granulator and maintains its axial position to ensure that the granulator remains properly aligned along its axis. The thrust roller is usually located on the downslope side of the granulator and is attached to the shell, which consists of a center shaft or journal and a roller assembly.

Compound Fertilizer Granulator Bearing Block

is the support structure for the rotary motion of the granulator and is responsible for fixing and guiding the trunnion bearings of the granulator. It is typically designed to accommodate the axial and radial forces generated during granulator rotation.

Pelletizer Cover

The compost pelletizer cover is located at the discharge end of the pelletizer and acts as a seal to retain heat and gas. The fertilizer granulator operates with steam piping, so Tom Lee uses SS304 linings and ceramic felts at both the front and rear ends to prevent heat leakage.

PLC control system

PLC is a digital computer-based system designed to automatically control various industrial processes. In rotary granulators, PLCs are used to monitor and control parameters such as temperature, speed, air flow, fuel flow, and other key variables that affect dryer performance and processed product quality.

Rotary granulator transmission

Rotary granulator transmission mainly consists of main transmission, sub-transmission, mechanical thrust wheel/hydraulic thrust wheel, motor, gearbox and other components, the unique design of the Tongli transmission can greatly improve the service life and safety performance of the equipment.

Our Products

We are the industry heads and produce the most reliable and trendy fertilizer production line solution you are looking for.

NPK compound fertilizer steam granulation solution

Suitable for making compound fertilizers, organic fertilizers and mixed fertilizers with diversified formulas with large output

NPK roller extrusion granulation method production

Save energy consumption, flexible output, small investment

High tower prilling method npk fertilizer production

Large investment, large output, suitable for making high-nitrogen NPK compound fertilizer

BB fertilizer blending line

Small investment, flexible output, and can mix a variety of formulas