What is pelletizing?

Imagine you take a pile of sand in your hand, squeeze it, and the sand gathers into a small clump. The process of pelletizing is a bit like that, but more delicate. We take tiny powders or particles and, through a specific process, gather them into uniformly sized, regularly shaped granules. These pellets can be round or other shapes, completely customized to our needs.

The granulation process has become an indispensable process for a wide range of industries due to its ability to precisely control granule characteristics, improve product quality, and its high degree of flexibility and customizability. From the traditional food, chemical, fertilizer production, and pharmaceutical industries to the emerging fields of materials science and biotechnology, the applications of the granulation process continue to expand.

Why do we need pelletizing?

Pelletizing offers many benefits, which is one of the reasons it has become so popular. It improves product performance, simplifies processing, and helps achieve desired properties. Here are some of the key benefits of granulation:

- Reduced dust: Pelletized products have significantly less dust, which not only improves the working environment, but also reduces material losses. For example, in agriculture, granular fertilizers are easier to apply accurately than powders and are less likely to be blown away by wind.

- Improved material properties: Through granulation, various physical properties of the product can be adjusted, such as flowability, dissolution rate, etc. This makes the final product more suitable for a particular application. This makes the final product more suitable for specific applications.

- Increased product value: Pelletized products are often considered to be of high quality and can have a higher market value.

- Ease of storage and transportation: Granular products are easier to store and transport than fine powders, reducing problems in packaging and handling.

The granulation process presents significant advantages over other pelletizing methods:

- Easier breakdown of granules and more timely release of nutrients: granulation drums produce lower density granules that are easier to break down than the higher density granules from roller pelletizing. This allows nutrients to be released quickly when needed, especially for products such as fertilizers and soil conditioners.

- Reduced wear and dust: Pelletizing produces rounded pellets with smooth edges, which effectively reduces friction and wear between the pellets, thereby reducing dust generation. This not only improves product quality, but also improves the production environment.

- Flexible formulation and product customization: Disc pelletizing, in particular, allows for a high degree of product customization by adjusting a variety of parameters, such as particle size distribution and compressive strength. Producers are able to accurately control product characteristics and create differentiated products according to market demand.

- Higher quality and competitiveness: Pelletizing technology produces pellets with good stability, long service life, and controlled release of nutrients, which can meet the needs of different application scenarios. These advantages together enhance the market competitiveness and added value of the products.

Pellet formation during granulation

Unlike processes that rely on high pressure, such as compaction granulation or briquetting, granulation is a wet process. The process aggregates fines into larger particles by adding moisture, usually in the form of a binder. Although the two terms are often used interchangeably, there is a difference between granulation and pelletizing. Pelletizing usually refers to the process of extruding material through a die by squeezing to form cylindrical pellets, commonly found in industries such as wood, fuel and feed. Pelletizing produces pellets with sharp edges that tend to rub against each other and cause abrasion.

Pelletizing, by contrast, involves rolling fine materials into spherical pellets in the presence of a binder. This rolling process causes the fines to gradually stick together to form larger particles. The two main types of granulation equipment are rotating drums and disk granulators, with disk granulators being the more common.

Common Pelletizing Processes

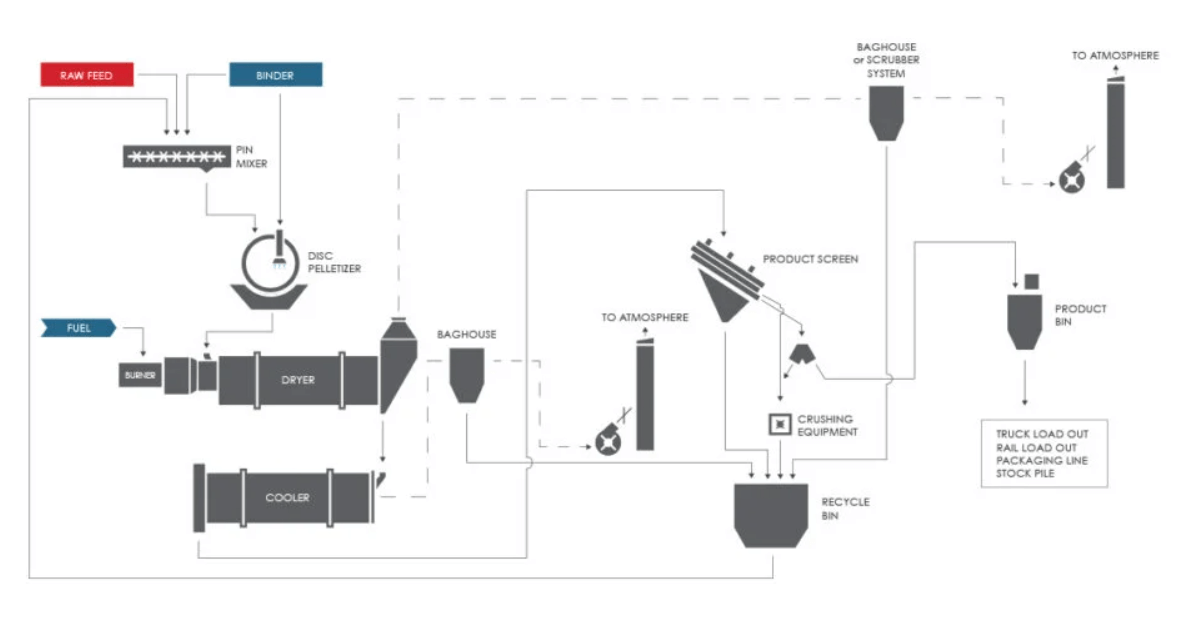

Pelletizing usually consists of the following steps:

Raw material preparation and pretreatment

Pretreatment of raw materials is an important part of the pelletizing process to improve product quality and productivity. Although not all granulation processes require pretreatment, this step can provide significant advantages such as increased throughput, reduced binder usage and improved end product properties.

Pretreatment is usually carried out in a needle mixer. For harder materials, pugmill mixers are also a good option. In these machines, the raw material is mixed continuously with the liquid binder at a constant rate. The pugmill mixer rotates at high speeds, mixing the solids and liquids well to form a homogeneous mixture. As the mixture tumbles, small agglomerates, or “seed pellets”, are formed.

Pelletizing process

After pre-treatment, the seed particles enter the disk granulator. In the case of untreated material, the raw material and the binder are continuously added to the disk directly from this step.

During the high speed rotation of the disk, new materials and binders are continuously added to ensure the continuous growth of the granules. The seed particles are mixed with the fines as they tumble over the disk, gradually adsorbing more fines to form larger particles. When the granules reach the desired size, they are subjected to centrifugal force and fly out from the edge of the disk.

The principle of the rotating drum granulator is similar to that of the disk granulator. The difference lies in the fact that the material rolls inside the inclined drum, gradually forming larger particles through constant tumbling and collision.

Post-processing: drying and cooling

Pellets from a granulator usually contain a certain amount of moisture and need to be dried. The drying process is usually carried out in a rotary dryer. The dried pellets may also need to be cooled to reduce their temperature and make them easier to handle.

The granulation process mainly involves the following equipment: Pin Mixers or blenders are used for pre-treatment to mix the raw material with the binder to form the seed granules; Disc Granulators or Rotary Drums are used to make the seed granules grow gradually by rotating them; and, finally, the Rotary Dryer is used to remove moisture from the granules to ensure the quality of the product. The synergy of these devices allows the pelletizing process to efficiently and consistently produce a pellet product that meets specific requirements.

What are the binders used in the pelletizing process?

During the granulation process, the binder is the key to aggregating fine particles into larger ones. According to the nature of raw materials and product requirements, commonly used binding agents include water, organic binders (such as starch, cellulose derivatives), inorganic binders (such as bentonite, water glass), polymer binders (such as polyacrylamide), sugars, proteins and synthetic resins. Different binders have different bonding mechanisms and scope of application. Water is the most common binding agent, while polymer binders provide stronger bonds. Choosing the right binding agent is the key to optimizing the granulation process and improving product quality.

Pelletizing technology has a wide range of applications

Pelletizing technology can be applied to virtually any powdered or slurry material, with common applications including gypsum, limestone, coal, fly ash, electric arc furnace dust, chemical powders and various ores.

Similarly, granulation has a wide range of applications in the fertilizer industry and is primarily used to convert powdered or fine-grained fertilizers into pellets that are easy to handle and apply. The following are specific applications of granulation in the fertilizer industry:

1. Improve fertilizer application efficiency

Pelletized fertilizer granules are easier to apply uniformly, reducing the risk of windblown and runoff. This allows the fertilizer to reach the target area more accurately and improves its effectiveness. For example, granulated nitrogen, phosphate and potash fertilizers are easier to control and distribute during application.

2. Improved physical properties of fertilizers

The flow and consistency of fertilizers is significantly improved through granulation. Granular fertilizers are easier to store, transport and apply than powdered fertilizers, reducing clogging and waste.

3. Reduction of dust and waste

The granulation process significantly reduces dust in the fertilizer, improving the working environment and reducing material waste. The reduction of dust not only improves the utilization rate of fertilizers, but also reduces the pollution to the environment.

4. Enhance the stability and durability of fertilizer

The granulated fertilizer particles decompose at a moderate rate in the soil and can provide sustained nutrient release. This is especially important for long-lasting and slow-release fertilizers, ensuring that plants receive a balanced supply of nutrients throughout the growth cycle.

5. Allows for the addition of multiple ingredients

The pelletizing process allows multiple nutrients and additives to be blended together to form a composite fertilizer. Such composite fertilizers can provide a wide range of essential nutrients to meet the needs of different crops and improve crop yield and quality.

6. Production of fertilizers for specific applications

Granulation technology can produce fertilizer products with specific particle size, strength and solubility according to different crops and soil conditions. For example, special fertilizers for different soil types or for specific crops.

How much does pelletizing equipment cost?

The price of granulation equipment varies greatly, mainly affected by equipment type, production scale, degree of customization, brand, technical level and market factors. For example, the price of small disc type granulator is relatively low, while the price of large industrial rotary drum granulator is up to millions or even tens of millions.

The main factors affecting the price of granulation equipment:

- Equipment size: the larger the processing capacity, the higher the price.

- Customization: the higher the degree of customization, the higher the price.

- Brand and quality: well-known brands and high-quality equipment prices are higher.

- Technical level: the price of equipment using advanced technology is higher.

How to choose the right pelletizing equipment for your industry?

Choosing the right pelletizing equipment for your industry is an important decision that requires consideration of several factors. Here are some suggestions for selecting pelletizing equipment:

- Define the characteristics of the raw material: first of all, understand the physical and chemical characteristics of the raw material to be processed, such as particle size distribution, moisture content, density, etc.. Different raw materials may require different types of granulation equipment.

- Determine the target product requirements: Define the specifications of the final product, such as particle size, strength, solubility, etc.. This will influence the selection of equipment and parameter settings.

- Evaluate the production scale: Select equipment with appropriate capacity according to the expected production scale. Small-scale production may be suitable for a disk granulator, while large-scale continuous production may require a rotating drum.

- Consider Process Flexibility: If frequent adjustments to process parameters are required or if different sizes of product are produced, a disk granulator usually offers greater flexibility.

- Space constraints: Consider the available plant space. Disk granulators have a smaller footprint, while rotating drums require more space.

- Energy and maintenance costs: Evaluate the energy and maintenance requirements of different equipment and select the one with lower long-term operating costs.

- Environmental factors: Consider the dust removal and noise level of the equipment to ensure compliance with environmental requirements.

- Compatibility with existing production lines: New equipment should be able to integrate seamlessly with existing production lines and auxiliary equipment.

- Supplier support: Choose a supplier who can provide comprehensive technical support, training and after-sales service.

- Conduct trials: Before making a final decision, it is recommended to conduct small-scale trials or commission a professional organization to conduct a feasibility study.

- Consider future development: Choose equipment with some upgrading and expansion capabilities to accommodate possible future changes in demand.

- Industry experience: Choose an equipment supplier with extensive experience in your industry, who can often offer a more tailored solution.

By taking these factors into consideration, along with specific industry needs and budgetary constraints, you can select the granulation equipment that is best suited for your industry. It is recommended that you fully consult with industry experts and equipment suppliers before making a final decision.

Conclusion

Pelletizing technology is a highly valuable process that is used in a wide range of industries. It not only significantly improves product performance, but also simplifies processing, optimizes application and ultimately creates high-quality products that meet specifications.

As a pioneer in the field of granulation, TONGLI has been committed to providing superior customized solutions since 1958. Our services cover the entire pelletizing process, including:

- material testing: to ensure that the raw material is suitable for pelletizing and to optimize process parameters

- product design: customizing pellet characteristics to customer needs

- process development: innovation and optimization of the pelletizing process to improve efficiency and product quality

- equipment customization: providing the most suitable pelletizing equipment for your needs.

Whether you are looking to improve product quality or develop new pelletizing applications, TONGLI can provide you with professional support and solutions. Feel free to contact us to discuss how we can utilize our extensive pelletizing experience and advanced technology to create value for your business.