No.1 Brand new dryer Manufacturer-organic inorganic drying equipment

Why drying is important?

Why organic fertilizer dryer is important? In industry, almost all raw materials need to be dried before entering processing and production. After the industrial products are manufactured and formed, they need to be dried again. The fields it involves are not limited to medicine and food, but also include countless industries such as spray painting, printing and dyeing, building materials, glass and welding andmost importanly the fertilizer industry. Why is drying so important in terms of the final product quality?

What is the working principle of drying?

The meaning of the word drying is very simple. It uses high temperature to remove excess moisture inside the material, or to create a dry environment to prevent the material from getting damp. It sounds similar to the fact that corn and wheat need to be exposed to the sun, but in fact, the drying problem in industry is more complicated. Take the production of organic fertilizers as an example. As an indispensable key link, the drying department plays a vital role. The strength of fertilizer can only reach the standard after drying.

Why organic fertilizer needs to be dried?

Because in the fertilizer industry, the raw materials of compound fertilizers are various powders, and water often needs to be added for granulation, which makes the initially produced fertilizer contain a certain amount of water. The moisture content of the raw materials is about 13 to 15, and the final moisture content of qualified fertilizer generally needs to be controlled between 2% and 3%, which requires drying equipment to evaporate most of the moisture in the fertilizer.

What are the types of fertilizer dryer?

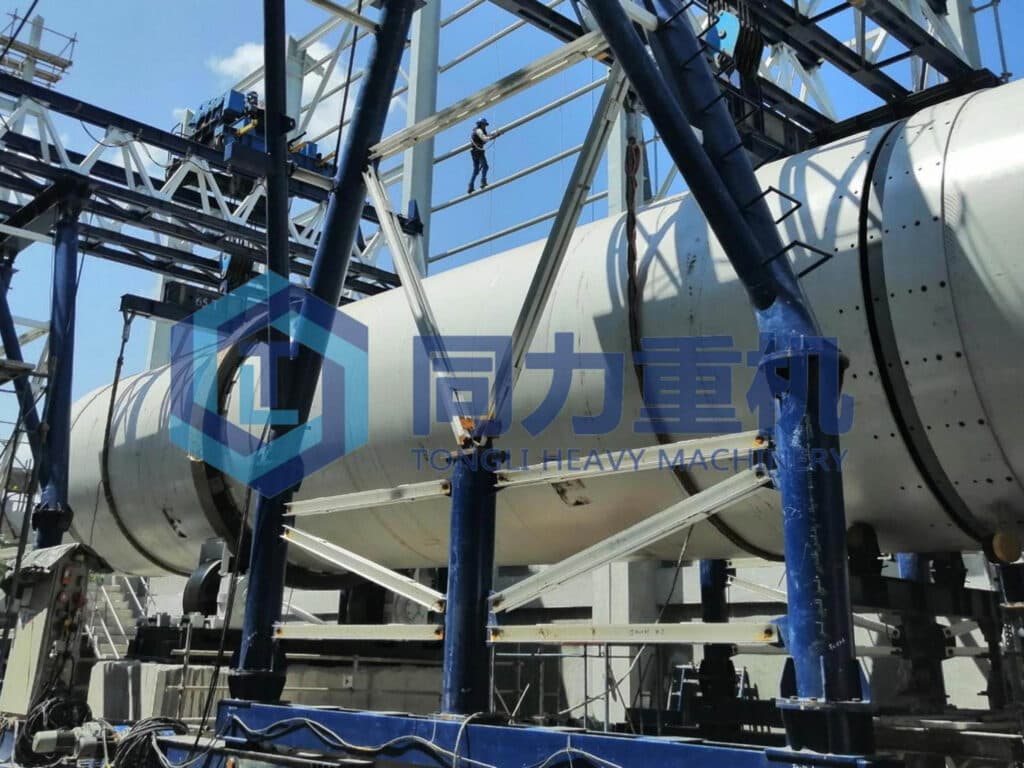

According to the structural form, dryers can be divided into: drum dryers; mesh belt dryers; box dryers, etc. Among them, the drum type is the most commonly used type. There are also types of drying rooms such as vacuum adsorption type and far infrared heating type. Drying equipment can be divided into three types according to the fuel used: coal type (coal or fuel oil), gas type and electric heating type.

- Coal-fired types include chain boilers and circulating fluidized beds;

- Gas type includes hot water type and steam type;

- Electric heating includes resistance wire heating tubes and heating cables;

How to dry organic fertilizer?

Organic fertilizer dryers commonly use high-temperature hot air drying technology to achieve material drying. The material is in contact with high-temperature hot air, thereby greatly reducing the moisture content of the organic fertilizer material. The organic fertilizer material containing moisture first enters the dryer drum through the conveyor. Under the action of high-temperature hot air in the dryer drum, the moisture of the organic fertilizer material continues to evaporate and reduce until the dried organic fertilizer material is discharged from the discharge port. discharge

How to operate the fertilizer dryer? Operation guide-important!

Thing to be careful when operating the fertilizer dryer

- There are a few things you need to pay attention to when drying fertilizers:

Temperature control: The temperature should not be too high during drying. It is recommended to control it between 60-80 degrees Celsius to avoid affecting the organic components in the fertilizer. - Time control: The drying time should not be too long. It is recommended to control it between 2-3 hours to avoid excessive drying and loss of nutrients in the fertilizer.

- Safety measures: Pay attention to safety during the drying process to avoid fire

How to select a good chemical fetilizer dryer manufacturer?

- Manufacturer’s reputation and experience: Understand the manufacturer’s reputation and experience in the industry. You can check their history, customer reviews and reference cases to choose a manufacturer with a good reputation.

- Product quality and technology: Evaluate the quality and technical characteristics of the equipment. Learn about equipment performance, durability, energy efficiency, and more and compare it with other manufacturers.

- Customization capabilities: If you have special requirements or need customized equipment, make sure the manufacturer has the appropriate capabilities and experience to meet your specific needs.

- Visit the factory or sample equipment: If possible, visit the manufacturer’s factory in person or view their sample equipment. This gives you a more intuitive understanding of their production process and equipment quality.