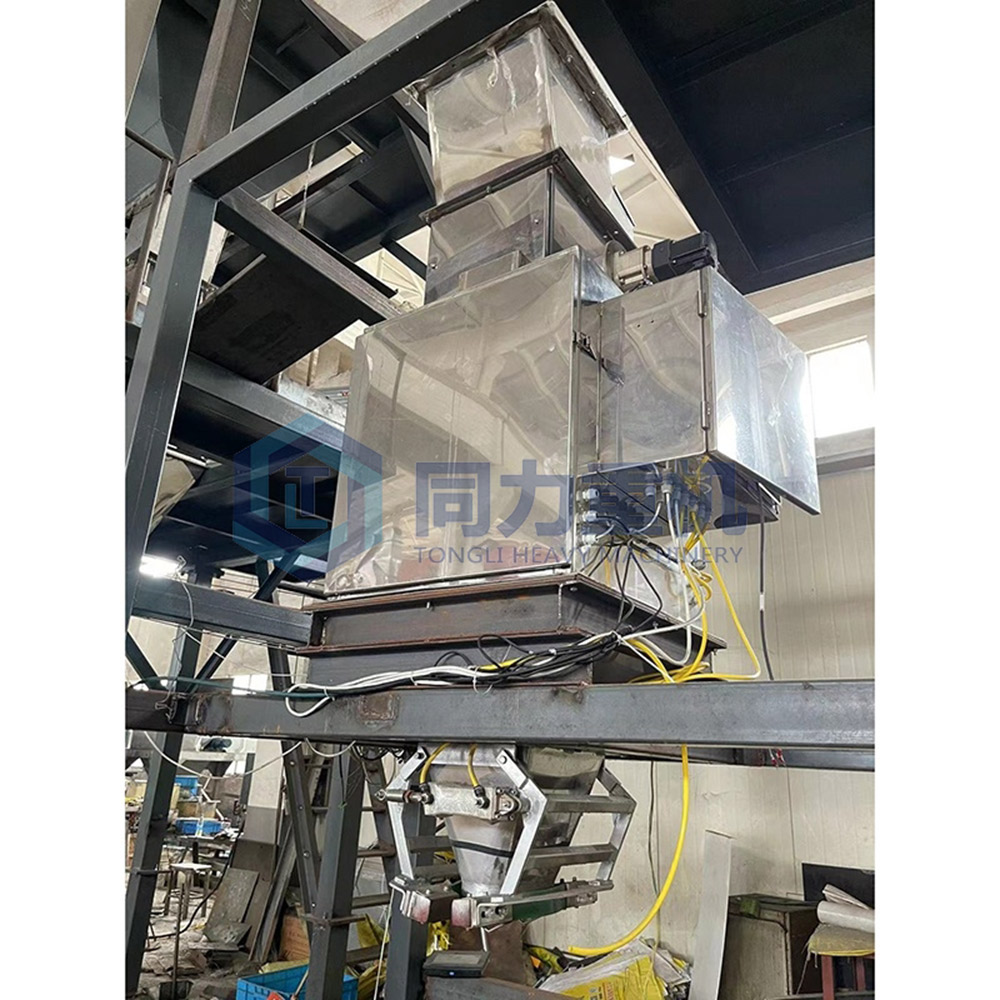

In today’s fast-paced agricultural landscape, the Tongli Fertilizer Automatic Packing Machine stands out as a game-changer, revolutionizing fertilizer packaging with unmatched efficiency and precision.

By automating the filling, sealing, and labeling processes, these machines not only streamline operations but also significantly reduce the risk of errors, making them essential for modern fertilizer manufacturing facilities.

Designed for versatility, Tongli machines cater to various fertilizer types—from granular to powder—ensuring that each production line operates at peak performance.

With features like high-speed output and user-friendly interfaces, the Tongli Fertilizer Automatic Packing Machine is your partner in achieving both productivity and quality in every bag.

Overview of Tongli Fertilizer Automatic Packing Machines

The Tongli Fertilizer automatic Packing Machines are designed to beautify the efficiency and accuracy of fertilizer packaging operations. Utilising current era, those machines automate the filling, sealing, and labeling methods, ensuring high-velocity operations with minimal human intervention. This no longer only optimizes manufacturing but also extensively reduces the probability of errors, making them an crucial asset for cutting-edge fertilizer manufacturing centers.

| characteristic | Description |

|---|---|

| Automation degree | completely computerized with % manipulate structures |

| Output capability | as much as 1200 baggage/hour |

| Accuracy | ±0.2% consistent with bag, ensuring unique weight control |

| Bag types | supports diverse bag substances such as poly, paper, and woven polypropylene |

| Operational features | person-friendly interface with touch display controls |

Engineered to deal with a huge variety of fertilizer types, from granular to powder, Tongli machines offer bendy answers tailored to the unique needs of every manufacturing line. Superior sensors and manipulate structures make sure constant overall performance beneath various operational situations, further enhancing their utility in dynamic production environments.

Key Features of Automatic Packing Machines for Fertilizers

The Tongli Fertilizer computerized Packing machine includes various high-tech capabilities designed to enhance the performance and accuracy of fertilizer packaging operations. A standout function is its superior weighing and dosing machine, which ensures unique weight control, minimizing cloth waste and enhancing price-effectiveness.

This machine additionally consists of a modern day manage machine, which lets in for easy changes and real-time tracking of the packing technique. The user-pleasant interface guarantees that operators can quick make modifications to conform to distinctive styles of fertilizers, improving flexibility in production.

durability is some other vital aspect, with the system created from incredible substances proof against the corrosive nature of fertilizers. This sturdy layout extends the system’s lifespan and reduces the frequency and value of renovation.

the mixing of automated bag placement and sealing era further streamlines the packing method, decreasing labor necessities and increasing the speed of packaging operations. This generation now not simplest hastens the technique but additionally enhances the safety of the operation, defensive employees from direct publicity to potentially dangerous substances.

finally, the system’s compact layout makes it best for factories with restricted space, imparting high efficiency with out requiring a large footprint. This feature permits for less complicated integration into current manufacturing strains, optimizing usual plant layout and workflow.

Benefits of Using Automatic Packing Machines in Fertilizer Production

the mixing of Tongli Fertilizer automatic Packing Machines into fertilizer production lines significantly enhances operational performance and product high-quality. Those machines automate the filling and sealing technique, making sure particular weight manipulate and minimum product wastage.

one of the number one blessings of the use of those machines is the sizable increase in packaging speed. Tongli’s superior generation lets in for speedy adjustment to distinct packaging sizes and weights, facilitating a unbroken transition between distinct styles of fertilizers.

| feature | advantage |

|---|---|

| high Precision Weight manage | Reduces material wastage and guarantees products are sold at correct weight specs. |

| automated Sealing Mechanism | enhances package integrity, protective the contents from contamination and moisture. |

| consumer-pleasant Interface | Simplifies operations and reduces the want for tremendous training. |

additionally, Tongli machines are prepared with advanced protection features that defend operators from ability hazards associated with guide packing techniques. The inclusion of automated diagnostic equipment additionally facilitates within the early detection of any operational issues, as a result decreasing downtime and maintenance prices.

The environmental impact of the usage of automatic packing machines is significantly wonderful. These systems use materials more efficaciously and can substantially decrease the carbon footprint of packaging operations through lowering fabric waste and strength intake.

Types of Fertilizer Materials Compatible with Tongli Machines

Tongli Fertilizer automatic Packing Machines are designed to handle a huge range of fertilizer substances, ensuring versatility and efficiency in packaging operations. The compatibility of these machines extends to numerous forms of fertilizers which includes granular, powder, and crystalline forms.

For granular fertilizers, Tongli machines are ready with precision weighing and filling structures that limit product waste and make sure accurate packaging weights. The sturdy construction of the equipment permits for the dealing with of coarse and irregular granular materials, which are common in mineral-based totally fertilizers inclusive of NPK (Nitrogen, Phosphorus, Potassium) blends.

in the case of powder fertilizers, such as urea and ammonium sulfate, the machines incorporate dirt manipulate technology to save you contamination and loss at some point of the packing system. These capabilities also improve the operating surroundings by using reducing airborne particles.

Crystalline fertilizers, including ammonium nitrate and monoammonium phosphate, require special attention to moisture manage to prevent caking. Tongli’s automated packing machines include sealed packaging alternatives that help maintain the integrity of those hygroscopic substances.

The adaptability of Tongli machines to a various variety of fertilizer kinds is complemented by using their capability to deal with multiple packaging sizes and materials, from small baggage appropriate for retail markets to large sacks intended for industrial use. This flexibility makes Tongli packing machines perfect for fertilizer manufacturers looking to optimize their packaging traces for maximum productiveness and minimum downtime.

Maintenance Tips for Longevity and Efficiency of Tongli Machines

retaining Tongli Fertilizer automated Packing Machines optimally is vital for making sure their durability and operational efficiency. Everyday and thorough maintenance now not handiest prevents sudden breakdowns but also enhances the machine’s overall performance over its lifecycle. Under are crucial preservation suggestions for these machines.

normal cleaning agenda

implementing a regular cleaning ordinary is crucial. Residual substances from fertilizers can cause clogging and corrosion if left unchecked. It is encouraged to easy the device surfaces and internal additives each day, mainly after widespread use, to prevent buildup and ensure smooth operation.

Lubrication of transferring parts

regular lubrication of the device’s moving components reduces friction, which in flip minimizes put on and tear. Use handiest producer-encouraged lubricants. Check and refill lubricant tiers weekly or consistent with the operational guide supplied by way of Tongli.

regular Inspection and replacement of Worn parts

common inspection is important to pick out and update worn or broken parts. Pay unique interest to seals and bearings, that are vulnerable to wear due to regular use. Scheduled inspections must arise month-to-month, with immediate alternative of elements displaying tremendous put on.

software Updates and Calibration

maintaining the machine’s software up to date is essential for performance. Updates can include new capabilities that enhance efficiency or restoration current insects. Calibration of weighing and packing systems should be performed quarterly to make certain accuracy and consistency in packaging.

professional Servicing

Annual servicing with the aid of a licensed Tongli technician is usually recommended. Those carrier exams include a comprehensive assessment of mechanical, electric, and operational structures to make sure all additives feature successfully and effectively.

| maintenance hobby | Frequency | information |

|---|---|---|

| cleaning | each day | smooth device surfaces and inner additives to do away with fertilizer residues. |

| Lubrication | Weekly | observe encouraged lubricants to transferring parts. |

| part Inspection and replacement | month-to-month | inspect and replace worn or damaged elements consisting of seals and bearings. |

| software Calibration | Quarterly | update software and calibrate weighing and packing structures. |

| expert Servicing | yearly | service via an authorized Tongli technician to evaluate and preserve all machine structures. |

Following those protection guidelines will help keep the operational efficiency and make bigger the lifespan of your Tongli Fertilizer automatic Packing Machines, ensuring they keep to operate at top performance all through their provider existence.

Case Studies: Successful Implementations of Tongli Packing Machines

Tongli Fertilizer computerized Packing Machines had been instrumental in enhancing manufacturing efficiency throughout numerous agricultural sectors. These case research spotlight the effectiveness and adaptability of Tongli machines in actual-global situations.

| Case have a look at | location | Fertilizer kind | outcome |

|---|---|---|---|

| AgriCo Fertilizers | Midwest america | NPK Blends | extended manufacturing pace by way of 20%, decreased hard work expenses through 15% |

| GreenGrow Organics | South Africa | organic Compost | better packing accuracy, minimized product waste through 10% |

| eastern AgriTech | India | Compound Fertilizers | Streamlined operations and improved protection requirements |

each of these case studies demonstrates Tongli‘s capacity to tailor solutions to diverse fabric characteristics and operational demands, confirming the logo’s dedication to innovation and consumer pleasure inside the fertilizer enterprise.