Welcome to an insightful exploration of the bucket elevator introduction

where we delve into the essential role these systems play in material handling across various industries. From agriculture to construction, Tongli’s innovative designs ensure efficient vertical transportation while minimizing downtime and maximizing performance.

In this article, we will uncover the key components, advantages, and future trends of Tongli bucket elevators

highlighting their versatility and robust construction. Join us as we navigate through the benefits of these reliable systems that are transforming the landscape of bulk material handling.

Overview of Bucket Elevators in Material Handling

Bucket elevators are fundamental components within the fabric dealing with industry, designed for vertical conveying of bulk materials. From grains in agriculture to cement in creation, those elevators are vital for efficient material shipping. Tongli focuses on an expansion of bucket elevators tailored to meet particular industry desires, making sure high efficiency and operational reliability.

The center mechanism of a bucket elevator consists of a sequence of buckets attached to a belt or chain with great tensile power and sturdiness. These buckets shipping substances from the lower level to the higher stage as the belt rotates across the power and tail pulleys. This gadget is designed for coping with materials vertically, particularly whilst space constraints prevent the use of different styles of conveyors.

| element | characteristic | fabric |

|---|---|---|

| Buckets | bring the majority material | metallic, Plastic |

| pressure Pulley | offers the necessary torque to transport the belt | forged Iron, steel |

| Belts/Chains | helps the load of buckets and bulk fabric | Rubber, metallic |

Tongli‘s bucket elevators are designed to be robust and efficient. Our engineering teams awareness on minimizing spillage and keeping the integrity of the substances being transported. Furthermore, the vertical design of our elevators appreciably reduces the footprint, making them perfect for industries where area is at a top rate.

every issue of the bucket elevator is engineered to offer a long provider life, lowering downtime and maintenance costs. Tongli offers custom designed solutions primarily based on the unique needs of your operation, making sure that every system is optimized for max overall performance and value-performance.

Key Components and Functionality of Bucket Elevators

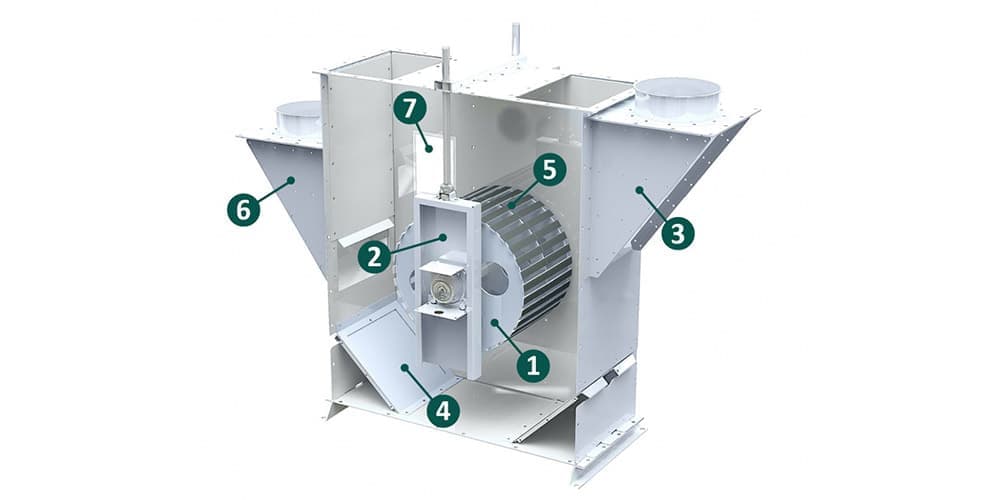

A bucket elevator, essential for cloth managing within diverse industries, includes numerous important additives that make sure its green operation. The core factors encompass the buckets that bring the materials, the belting or chain to which the buckets are attached, the force and motor mechanism that powers the system, and the head and tail pulleys which facilitate motion.

The functionality of a bucket elevator starts with the loading of substances into the buckets from a decrease station or hopper. Because the belt or chain ascends, pushed via the motor, the buckets shipping the substances to a better level in which they may be discharged. This discharge technique typically includes a centrifugal pressure created through the rotation of the pinnacle pulley, which suggestions the buckets and releases the substances. For greater delicate dealing with or to prevent spillage, a few bucket elevators are designed with a gravity-caused discharge mechanism.

Tongli designs its bucket elevators with a focal point on maximizing toughness and minimizing upkeep necessities. They use strong materials to construct the buckets and belts, ensuring they could take care of the mechanical strain and weight of transported substances. Additionally, Tongli includes advanced drive systems that aren’t only effective but additionally energy-green, aligning with the cutting-edge enterprise requirements for sustainability.

every element of Tongli’s bucket elevators is engineered to fulfill specific operational demands, thinking about elements along with material kind, transport top, and throughput requirements. This tailor-made engineering technique ensures that every bucket elevator performs optimally in its supposed application, imparting reliability and powerful cloth managing solutions across various industries.

Different Types of Bucket Elevators Offered by Tongli

Tongli Heavy machinery gives a various range of bucket elevators designed to satisfy diverse fabric coping with necessities in a couple of industries. Every kind is engineered to enhance operational performance and safety.

| type | traits | number one packages |

|---|---|---|

| Centrifugal Bucket Elevator | utilizes centrifugal force to discharge substances at excessive speeds; appropriate for coping with quality, loose-flowing materials. | Grain processing, sand, small coal |

| continuous Bucket Elevator | Operates at a lower velocity to make sure gentle handling; perfect for fragile or abrasive substances. | chemical compounds, minerals, and foundry substances |

| fantastic Discharge Elevator | Designed for sticky substances; makes use of a aggregate of gravity and centrifugal force for discharge. | Sugar, wet and sticky substances |

Tongli’s bucket elevators are custom designed to healthy particular operational requirements, ensuring ultimate overall performance with minimum protection. The choice of the bucket elevator type by using Tongli is based on thorough cloth feature evaluation and alertness demands to provide a tailored solution.

Advantages of Using Tongli Bucket Elevators

Tongli bucket elevators are designed to deal with a wide variety of bulk substances efficiently and reliably. Our advanced engineering techniques make certain that every elevator offers greatest performance, durability, and ease of renovation. Right here are the important thing advantages:

better efficiency

The design of Tongli bucket elevators maximizes throughput and minimizes spillage. We make use of precision production strategies to create components that healthy flawlessly, ensuring clean and continuous operation. This efficiency is critical in high-extent operations common in industries including agriculture, mining, and cement manufacturing.

durability

Our bucket elevators are constructed with splendid substances selected for his or her durability and sturdiness. Every unit undergoes rigorous checking out to ensure it may resist the demanding conditions of industrial environments. This sturdiness reduces downtime and upkeep costs, offering an extended service existence.

Versatility

Tongli bucket elevators are to be had in numerous configurations to healthy different material traits and operational requirements. Whether or not you want a low-pace elevator for fragile materials or a high-pace gadget for efficient vertical delivery, we’ve got an answer that suits your needs.

Customizable alternatives

We provide more than a few customization alternatives to ensure that our bucket elevators meet the specific needs of your software. From one of a kind bucket substances to variable speeds and a couple of discharge structures, our elevators may be tailored to suit your genuine specs.

smooth preservation

Our bucket elevators are designed with accessibility in thoughts, making it smooth to carry out recurring renovation and inspections. This accessibility allows prevent extended downtimes and guarantees constant operational efficiency.

Common Applications and Industries Served

Bucket elevators, especially those from Tongli, are extensively utilized throughout a selection of industries because of their efficiency in handling bulk substances. Those elevators are pivotal in vertical shipping, mainly while area constraints or excessive capacities are a concern.

| enterprise | utility |

|---|---|

| Agriculture | Transporting grain, seeds, and feed |

| Mining | Conveying coal, ore, and quarry substances |

| chemical compounds | transferring bulk chemicals, fertilizers, and plastics |

| creation | elevating cement, sand, and aggregates |

| meals Processing | handling cereals, snacks, and other packaged goods |

The adaptability of Tongli bucket elevators is in addition evidenced by using their utility inside the strength and utility area, where they are used to manage ash and other by-products. No longer best do those elevators serve simple material shipping desires, in addition they align with industries requiring stringent hygiene standards, consisting of the pharmaceutical and food sectors. This versatility makes them an crucial component in diverse operational contexts.

Maintenance Tips for Prolonging the Lifespan of Bucket Elevators

right maintenance is essential for making sure the durability and highest quality overall performance of bucket elevators. Via adhering to a based preservation schedule, you may considerably expand the provider existence of those important additives in cloth handling operations. Below are key strategies advocated with the aid of enterprise experts, inclusive of the ones from Tongli, to maintain bucket elevators efficiently.

everyday Inspection and tracking

conduct normal inspections to perceive and address capacity issues earlier than they boost. Key regions to recognition on consist of the integrity of buckets, belt alignment, and the circumstance of electrical automobiles and bearings. It is really helpful to carry out these inspections at the least quarterly, depending at the elevator’s usage depth.

cleaning Protocols

keeping cleanliness within bucket elevators prevents fabric construct-up, which can result in malfunctions or untimely wear. Make sure that the buckets, belts, and discharge areas are unfastened from debris. This now not most effective enhances efficiency however also reduces the danger of infection, mainly in food processing applications.

Lubrication of moving elements

everyday lubrication of the elevator’s shifting additives, together with bearings, chains, and gears, is critical. Use only remarkable lubricants encouraged by using the manufacturer, which in this example would be Tongli. Proper lubrication reduces friction, that can purpose immoderate put on and tear.

Alignment and tension Adjustment

proper alignment and tension of the elevator belt are essential for clean operation. Misalignment can result in choppy belt wear and multiplied strain on the system. Take a look at the alignment periodically and alter the anxiety as had to avoid slippage and make sure green electricity transmission.

replacement of Worn elements

update worn or damaged components promptly to hold the performance and safety of the bucket elevator. This consists of buckets, belts, and pressure mechanisms. Always use real alternative elements from Tongli to guarantee compatibility and overall performance.

training for Operators

make sure that operators are well-trained in the proper operation and upkeep strategies of bucket elevators. Complete schooling helps in recognizing early symptoms of trouble and in accomplishing ordinary preservation effectively.

by enforcing these renovation techniques, customers of Tongli bucket elevators can make certain their equipment operates reliably over its supposed lifespan, thereby maximizing productiveness and minimizing downtime in their material coping with operations.

Future Trends in Bucket Elevator Technology

The landscape of bucket elevator era is unexpectedly evolving, driven via improvements in fabric technological know-how, automation, and ecological considerations. Tongli is at the forefront of those innovations, usually integrating cutting-edge features into their designs to meet the converting needs of material managing.

Automation and clever systems

One extensive fashion is the mixing of automation and smart manage systems into bucket elevators. These systems enhance operational performance and protection with the aid of allowing real-time tracking and manage of overall performance parameters. Sensors can locate capability issues which includes blockages or system malfunctions early, thereby decreasing downtime and preservation costs.

materials and layout innovations

Advances in substances technology are main to the improvement of lighter, extra durable, and corrosion-resistant materials. Those improvements no longer handiest make bigger the lifespan of bucket elevators however also lessen the strength required for operation. Tongli is exploring using high-electricity alloys and composites which can resist harsh environments, in particular in industries like mining and chemicals.

green technologies

Environmental sustainability is becoming an increasing number of critical in cloth coping with. Tongli is actively growing greater strength-efficient models and incorporating functions that minimize dirt emissions and noise, contributing to a decrease environmental footprint. This technique not best helps compliance with international environmental requirements however additionally aligns with the sustainability goals of many industries.

Modular and Scalable Designs

Flexibility in design is critical for adapting to numerous operational necessities. Tongli’s modular bucket elevators are designed to be without problems scalable, taking into consideration changes in capability and peak without widespread disruptions. This modularity ensures that organizations can scale their operations up or down with minimal investment in new device.

desk: Key future improvements in Tongli Bucket Elevators

| fashion | capabilities | blessings |

|---|---|---|

| Automation and smart manipulate | real-time tracking, early issue detection, automated adjustments | accelerated efficiency, reduced downtime, more desirable protection |

| advanced materials | high-strength alloys, corrosion-resistant composites | Longer lifespan, reduced operational costs |

| eco-friendly Designs | power-green models, decreased emissions | Environmental compliance, decrease carbon footprint |

| Modular construction | easily adjustable ability and peak | flexible, fee-powerful scalability |

As Tongli keeps to innovate in the realm of bucket elevator generation, these developments are expected to shape the future of fabric coping with, presenting more advantageous answers that aren’t handiest efficient but additionally environmentally accountable and adaptable to a number of commercial programs.