Super-Capacity Bucket Elevators Ideal for High-Tonnage Jobs

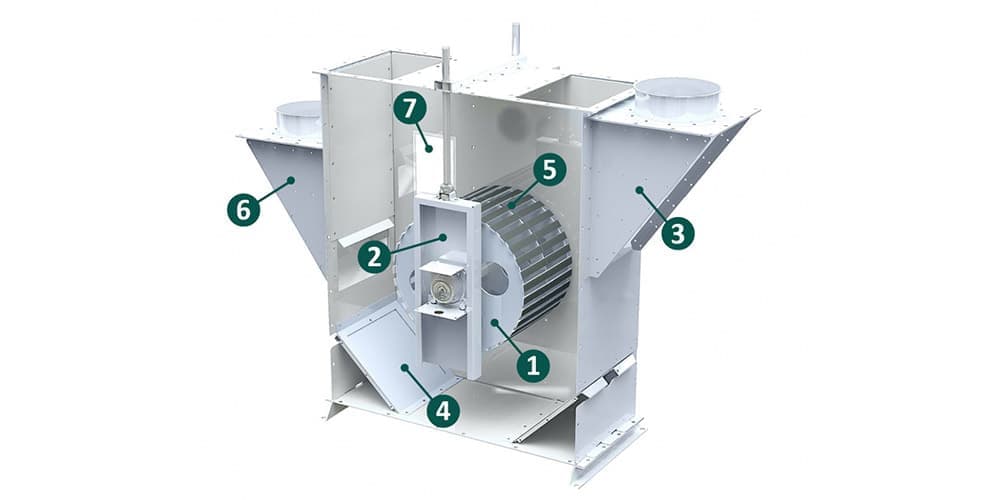

The Bucket Elevator is the equipment of choice for vertical material handling in mines, manufacturing plants and other facilities. It is highly customizable and capable of handling a wide variety of free-flowing materials, completing conveying tasks quickly and reliably.

However, in some cases where extremely high throughputs need to be handled, the capacity of a standard bucket elevator may not be sufficient. This is where an oversized bucket elevator becomes the ideal alternative to multiple standard units.

What is an oversized bucket elevator?

The term “Ultra Capacity” is an industry term that refers to double chain continuous bucket elevators. These elevators are available in a variety of sizes with capacities ranging from a minimum of approximately 100 tons per hour to a maximum of 800 tons per hour.

With a nominal internal size of 82 inches wide by 66 inches deep, the TONGLI Ultra Capacity Elevator fills a critical gap in the market for high-capacity vertical material handling.

Design and Manufacturing Considerations

Considerations for designing and building an oversized capacity hoist are much the same as for a standard hoist, with some exceptions.

The following factors are involved in the design and construction of all bucket elevators:

- Discharge height

- Capacity

- Chain speed

- Material packing density

However, the following factors must also be considered when designing an oversized capacity elevator:

Chain traction

Although mechanically identical to a standard hoist, the design and construction of an oversize capacity hoist needs to be more robust due to the high tonnage of the oversize capacity hoist. This is particularly evident during the design of chain traction, adding to the complexity of the design.

The chain tractive effort is the total weight of the material, bucket and chain. While chain traction has an impact in the design of standard hoists, it is much less influential.

When designing oversize hoists, manufacturers must pay careful attention to the following areas:

Head Shaft Size: In order to counteract chain traction, TONGLI employs a number of key design modifications. We use larger head shafts, up to 13 inches in diameter (compared to standard head shafts, which are typically no more than 8 inches).

Chain Load: We also use a higher load chain, rated at 40,000 lbs. The most significant difference is that we use two chains instead of the standard single chain. This helps to share the extra load through the two chains. By doing this, we can ensure that the chain traction does not add stress to the unit or risk overloading the components.

Enclosure design: When designing a self-supporting (self-supporting, or in other words, with no structural steel support at the head) hoist, chain traction is even more important because the enclosure design must be able to support the weight of the entire unit.

Bucket Elevator Tension Compensators

TONGLI also utilizes an internal gravity tension compensation device for oversized capacity hoists. This tension compensation device offers several key advantages in this setup:

- It is self-tensioning, minimizing human interaction and negligence.

- It requires virtually no maintenance.

- The boot shaft does not penetrate the housing, eliminating the potential risk of material leakage at this point.

Housing Welding

The larger casing dimensions of the Oversize Hoist provide the opportunity to internally seal welded casing corners. This is a major advantage when working with corrosive materials as it prevents moisture and material from building up between the casing and the vertical angle, thus eliminating a common point of corrosive wear.

In hoists that use structural steel support in the head, we have implemented an expansion joint underneath the head housing that allows the hoist to move or expand independently of the structural steel.

Bucket Size

Unsurprisingly, the buckets on oversized capacity hoists are also larger and capable of accommodating higher tonnages. Elevator buckets can measure up to 56 inches wide.

In addition to these modifications, we’ve incorporated all the features of our standard hoists, including:

- Removable top cover

- Access doors for easy maintenance

- Horizontally and vertically reinforced, precision welded head, boot and center sections

- Adjustable throat plate at discharge

- Inspection doors on both sides of discharge

- Available service platforms and access ladders

Applications

Oversized capacity hoists are used in plants that need to handle extremely high tonnages and would otherwise require multiple units to meet handling targets. For this reason, they are most commonly used at mining sites and mineral fertilizer plants. In particular, they have become the industry standard for potash mines.

How to choose the right Ultra Capacity Hoist for you?

Choosing the right Ultra Capacity Hoist for you requires consideration of the following key factors:.

- Handling capacity demand: to clarify their handling capacity requirements, according to the actual demand to choose the appropriate handling capacity specifications.

- Material characteristics: Consider the type of material to be conveyed, density, fluidity and other characteristics, choose the appropriate hopper design and chain strength.

- Installation space: The super-capacity elevator is large in size, so it is necessary to ensure that the installation site has enough space.

- Chain tension: Chain tension is an important consideration due to the high throughputs handled.

- Tensioning: Built-in gravity tensioners are recommended for automatic tensioning and low maintenance.

- Shell design: Consider the need for internal sealing welding and other corrosion-resistant designs.

- Hopper Size: Select the appropriate hopper size based on capacity, up to 56 inches wide.

- Ease of Maintenance: Choose a design with access doors, removable tops, etc. for ease of maintenance.

- Application Scenarios: High throughput scenarios such as mines and mineral fertilizer plants are best suited for overcapacity hoists.

- Manufacturer’s reputation: Choose an experienced and well-known manufacturer to ensure equipment quality and after-sales support.

By comprehensively considering the above factors, combined with the actual needs and budget, you can choose the most suitable super-capacity hoist. It is recommended to consult professionals to get more accurate advice when purchasing.

Conclusions

Ultra-capacity bucket elevators are ideal for handling high throughput materials. Although similar to standard elevators, they require special considerations in design and manufacture, such as the use of higher strength chains, larger header shafts and hoppers, to ensure safe and reliable operation at high capacities.

Since 1958, TONGLI has been the industry’s most trusted supplier of custom bucket elevators, including oversized capacity elevators.

For more information about our oversized capacity bucket elevators or other bulk material handling equipment, contact us today!