Rotary Kiln: Process Definition

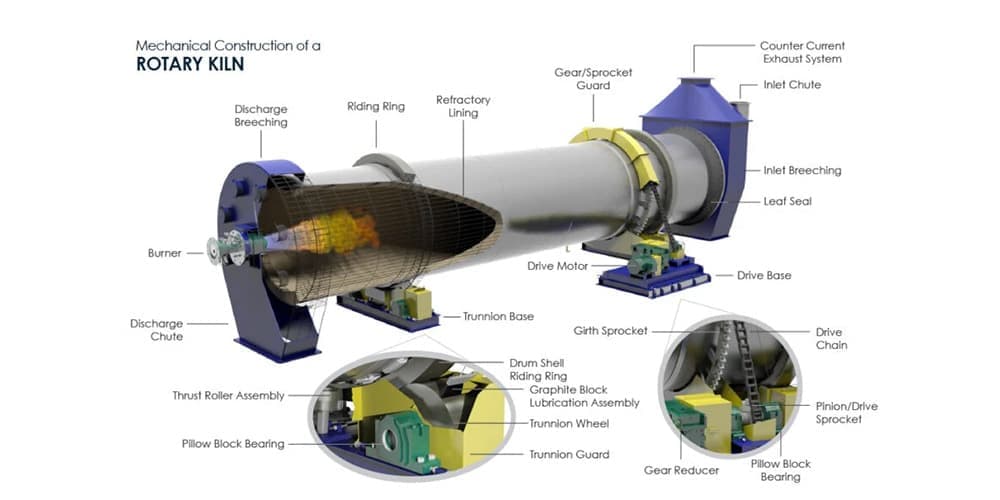

A rotary kiln is a widely used heat treatment facility. It consists of a rotating cylinder in which high-temperature combustion products flow in or around it, creating a precisely controlled environment for material property changes.

Due to the extremely high temperatures inside the rotary kiln, observing the phase change process of the material is very difficult and sometimes impossible. This has led to some misconceptions about the processes taking place inside the kiln and the many applications of rotary kilns. If you think that a rotary kiln may be the right equipment for your heat treatment needs, then understanding the various processes that can be performed in a rotary kiln is the first step in understanding its versatility.

Rotary Kiln Processes

The following are the main processes that can be performed in a rotary kiln.

Calcination

The process of calcination involves heating the material to a high temperature for the purpose of chemical decomposition (chemical separation). Calcination is commonly used to manufacture inorganic materials. The most common example is the decomposition of calcium carbonate into calcium oxide and carbon dioxide. The calcination process may also include the removal of bound water. An example is the removal of water from a viscous sludge. Since some of the water in the sludge is bound to solids, simple drying or pressing is not effective in removing all the water to make dry (ash) pellets.

Thermal Desorption

Thermal desorption utilizes heat to remove organic chemicals, such as pesticides, and separate them from inorganic minerals, such as sand. It is important to note that this is not an incineration process, which can produce harmful pollutants and require more extreme exhaust treatment systems. Instead, thermal desorption is a separation process that utilizes adsorbed minerals and chemicals at different reaction temperatures. Organic chemicals (e.g., pesticides) become volatile at elevated temperatures, allowing for separation without combustion.

Organic Combustion

Organic combustion is the thermal treatment of organic waste. This combustion process leaves behind ash that is greatly reduced in mass and volume. The most common use of this rotary kiln process is in waste treatment plants to reduce the volume of waste deposited in landfills.

Sintering

Sintering is the process of heating raw materials to near their melting point. The purpose of this process is to utilize the high internal temperature of a rotary kiln to increase the strength of the material. The most common use of this process is in the manufacture of synthetic proppants, where sand or ceramic materials need to remain structurally stable without adding mass.

Thermal sizing

This is the process of combining a heat-resistant core mineral with a less heat-resistant coating material. Similar to other coating processes, there is a core material and a coating material (usually mixed with a binder). The difference between this process and the unheated coating process is that the rotary kiln heats the coating material close to its liquefaction point. In this heated state, the material can be uniformly applied to the heat-resistant core and, because it is a chemical phase change, is more robust than conventional coating processes.

Reduction Roasting

Reduction roasting is the process of removing oxygen from a component of an ore, usually using carbon monoxide (CO), which is usually supplied by mixing a carbonaceous material (such as coal or coke) with the ore or supplying it separately. For example, hematite-containing materials are reduced and roasted to produce magnetite that can be magnetically separated.

Depending on the material and the desired end result, a rotary kiln may be a viable option for your thermal processing needs. The rotary kiln is a versatile piece of equipment that can be integrated into your existing process. There are several different options available on the market, such as direct and indirect heating (combustion chamber or heat shrink), each of which can be customized to increase residence time.

Rotary kiln applications

The rotary kiln has a wide range of applications, covering many fields such as building materials, chemical industry, metallurgy, mining, environmental protection and so on. Specific applications are as follows:

1. Building materials industry

- Cement production: rotary kiln is the key equipment for the calcination of cement clinker, which plays a vital role in cement production.

- Lime production: rotary kiln is used to calcine limestone and produce active lime, which is widely used in construction, chemical industry, agriculture and other fields.

- Ceramic granule production: rotary kiln is used to calcine ceramic granule, which is a kind of lightweight aggregate with the properties of heat preservation, sound insulation, fire resistance, etc. It is applied in the fields of construction, transportation and water conservancy.

- Refractories production: rotary kiln is used for calcining refractories, which are used in the high temperature parts of industrial furnaces and kilns to resist high temperature, corrosion and abrasion.

2. Chemical industry

- Soda production: rotary kiln is used to calcine manganese, limestone and table salt to produce soda, which is an important chemical raw material used in glass, paper, textile, medicine and other fields.

- Phosphate fertilizer production: rotary kiln is used to calcine calcium phosphate and phosphate, the production of phosphate fertilizer, phosphate fertilizer is an important raw material for chemical fertilizer.

- Compound fertilizer production: rotary kiln is used for calcining compound fertilizer, compound fertilizer is a kind of multi-nutrient fertilizer, containing nitrogen, phosphorus, potassium and other nutrients, is an indispensable fertilizer in agricultural production.

3. Metallurgical industry

- Iron ore roasting: rotary kiln is used for roasting iron ore, removing water and improving the grade of iron ore.

- Copper, aluminum, zinc and other non-ferrous metal ore roasting: rotary kilns are used to roast copper, aluminum, zinc and other non-ferrous metal ores to remove moisture, sulfur and impurities, in preparation for subsequent smelting.

4. Mining industry

- Quartz sand roasting: rotary kilns are used to roast quartz sand, remove moisture and improve the purity of quartz sand.

- Feldspar Roasting: Rotary kilns are used to roast feldspar, which is used in the production of ceramics, glass and other products.

Rotary kiln is a widely used and powerful heat treatment equipment, which plays an important role in various fields. With the continuous progress of science and technology, the technology of rotary kiln is also developing and perfecting, and its application will be more extensive.

How to choose the right rotary kiln equipment?

Choosing the right rotary kiln equipment requires consideration of the following key factors.

- Production scale and capacity: According to the actual production scale and the required capacity to choose the right type of rotary kiln. Different models of rotary kilns have different parameters such as kiln size, output and speed.

- Material Characteristics: Select the suitable rotary kiln according to the type of material to be processed. Different materials may require different heat treatment process and equipment configuration.

- Technical parameters: detailed understanding of the technical parameters of each type of rotary kiln, including kiln size, output, rotational speed, supporting power, equipment size and weight, kiln body properties.

- Manufacturer’s strength: choose manufacturers with strong strength and rich experience. Examine the manufacturer’s production capacity, technical level and after-sales service.

- Price and quality: Compare the price and quality of products of different manufacturers, and choose cost-effective equipment.

- Convenience of maintenance: Consider the difficulty of maintenance and the supply of spare parts, and choose equipment that is easy to maintain.

- Customized demand: Communicate with the manufacturer to customize the design according to the special demand.

- Safety performance: pay attention to the safety performance of the equipment, such as overload protection, emergency stop and other functions.

When choosing rotary kiln equipment, it is recommended to compare three, fully understand the advantages and disadvantages of each manufacturer’s products, combined with the actual needs to make the best choice. At the same time, maintain good communication with the manufacturer to ensure that the equipment can meet the production requirements.

Rotary Kiln Equipment Manufacturer

TONGLI offers many different types of rotary kilns, including both direct firing and indirect firing (combustion chamber or heat shield). Each type of rotary kiln can be customized to meet specific customer needs, such as increasing retention time to optimize process results.

TONGLI offers rotary kilns with the following advantages:

- A wide range of types: can meet the choice of customers with different materials and different process requirements.

- Excellent performance: high combustion efficiency, high heat utilization rate, low tail gas emission.

- Reasonable structure: compact design, convenient operation and simple maintenance.

- Reliable operation: reliable quality, stable performance, long service life.

- Customized service: rotary kiln of various specifications and parameters can be customized according to customer requirements.

TONGLI is committed to providing customers with high quality rotary kiln products and services to help customers realize efficient and environmentally friendly production.

If you are looking for high quality and high performance rotary kiln, TONGLI will be your best choice.

Please feel free to contact TONGLI for more information.