Processing Phosphates for Use in the Fertilizer Industry

Phosphorus is an essential component of healthy plant growth and plays a key role in many biological processes, helping plants to develop strong stalks and root systems, increase disease resistance and improve overall productivity.

Phosphorus is primarily derived from phosphate rock, which is mined throughout the world. While powdered phosphate can be applied directly to the soil, processing it into a form that is more readily absorbed by plants can provide even greater benefits.

Phosphate ore can be processed into a variety of phosphorus fertilizers. Most commonly, it is processed into monoammonium phosphate (MAP) and diammonium phosphate (DAP) fertilizers.

MAP and DAP fertilizer production process

After the phosphate ore is mined, it needs to be beneficiated first to separate the useful phosphate ore from the impurities. This is usually a wet process, the product needs to be dried first. The drying process is usually carried out in a rotary dryer, an industrial drying system that is ideally suited to processing phosphate rock due to its robustness and large capacity.

The dried phosphate rock is most often processed into ammonium phosphates. This is done by reacting the phosphate rock with sulfuric acid to form phosphoric acid, which is then reacted with ammonia to form MAP or DAP.

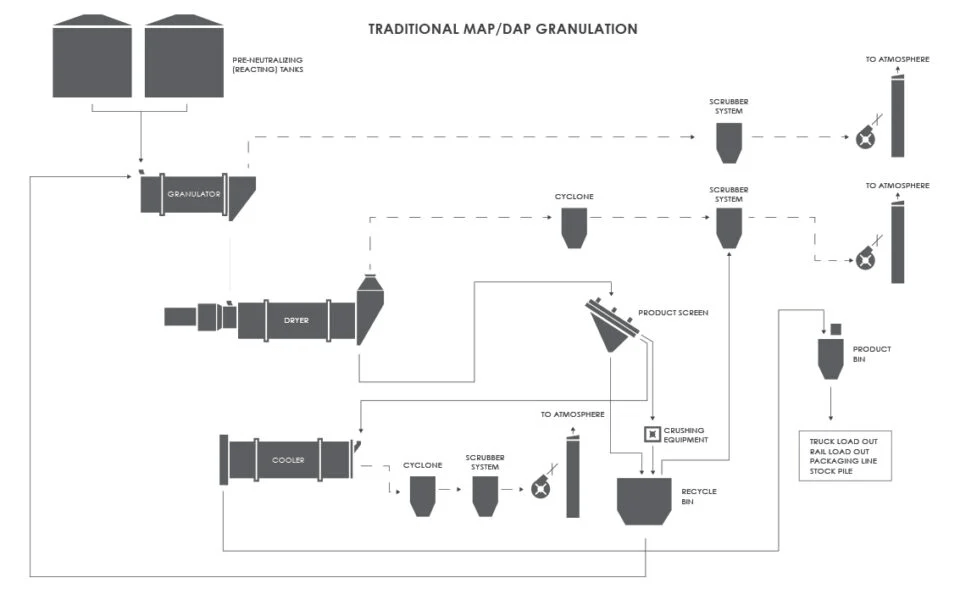

The process for producing MAP and DAP is as follows:

- Phosphoric acid and ammonia are pre-neutralized in a tank to form a slurry.

- This slurry is fed into a rotary drum granulator where it is tumbled in a drum and cured to form granules.

- These granules are fed through a conveyor or bucket elevator to the rotary dryer where they are dried to their final form. The tumbling action of the dryer further rounds and polishes the granules.

- The pellets leave the dryer and pass through a sieving process that separates oversized and undersized pellets. The oversized particles are crushed in a chain mill and re-entered into the process as recycled material along with the oversized particles.

- The qualified product enters the cooling process, usually using a rotary cooler, to prevent agglomeration during storage and to provide the necessary cooling if the material leaves the dryer at too high a temperature for subsequent material handling or packaging equipment.

Other Phosphate Fertilizer Products

Although phosphate rock is most often made into MAP and DAP, it can be made into a variety of other fertilizer products:

- Calcium Superphosphate (SSP)

- Heavy Calcium Superphosphate (TSP)

- NPK Compound Fertilizers – Although phosphorus is not the primary ingredient in this fertilizer, it is used in a variety of NPK formulations along with potassium and nitrogen.

The composition of these products may vary, but they are all produced using conventional granulation methods.

Conclusion

Phosphorus is a key component in maintaining healthy and productive crops. Although the majority of phosphate rock is used for the production of MAP and DAP fertilizers, a wide range of fertilizer products and blends can be made from this life-giving mineral through the granulation process.

The processing and utilization of phosphate fertilizers is crucial for modern agricultural production. Through reasonable processing technology, it can give full play to the role of phosphorus, provide crops with more easily absorbed and utilized nutrients, thus improving crop yield and quality and promoting sustainable agricultural development.

Fertilizer Production Equipment Manufacturer

TONGLI has been committed to the research, development and manufacture of fertilizer production equipment since its establishment in 1958. As a member of China Building Material Machinery Association, we have rich experience and innovation in the field of fertilizer equipment manufacturing. Our factory covers an area of more than 150,000 square meters and is equipped with more than 100 sets of heavy machinery and equipment, including CNC and other advanced equipment. Through these state-of-the-art manufacturing facilities, we are able to provide our global customers with customized heavy-duty fertilizer production equipment and systems to help them develop quality phosphate fertilizer products.

Our product line includes organic fertilizer production lines, NPK compound fertilizer production equipment, and more. These plants are used to produce a variety of phosphate fertilizers such as Monoammonium Ammonium Phosphate (MAP), Diammonium Ammonium Phosphate (DAP), Calcium Superphosphate (SSP), and Calcium Heavy Superphosphate (TSP).

With many years of experience in the industry, we understand the importance of improving the utilization of phosphate fertilizers. Our equipment can help our customers to achieve precise fertilization, improve the utilization efficiency of phosphate fertilizer, and reduce environmental pollution. If you want to know more about processing phosphate rock into fertilizer or need customized fertilizer production equipment, please feel free to contact us. Our professional team will provide you with the most suitable solutions.