Welcome to Sustainable Agriculture

Welcome to the world of sustainable agriculture, where the Organic Inorganic Compound Fertilizer Production Line at Tongli is revolutionizing how we nourish our crops. This article delves into the intricate processes that blend organic and inorganic materials, ensuring a balanced nutrient profile that enhances soil health and crop yield while adhering to eco-friendly practices.

Explore Cutting-Edge Technologies at Tongli

Join us as we explore the cutting-edge technologies and methodologies that Tongli employs in its production line. From raw material selection to granulation and quality control, discover how we are committed to delivering superior fertilizers that not only meet agricultural demands but also support environmental stewardship.

Overview of Organic-Inorganic Compound Fertilizer Production Processes

The manufacturing of natural-inorganic compound fertilizers is an problematic process that mixes the blessings of both organic depend and inorganic vitamins to create a balanced fertilizer product. At Tongli, we utilize modern-day generation and innovative methodologies to ensure the green and sustainable manufacturing of superb fertilizers.

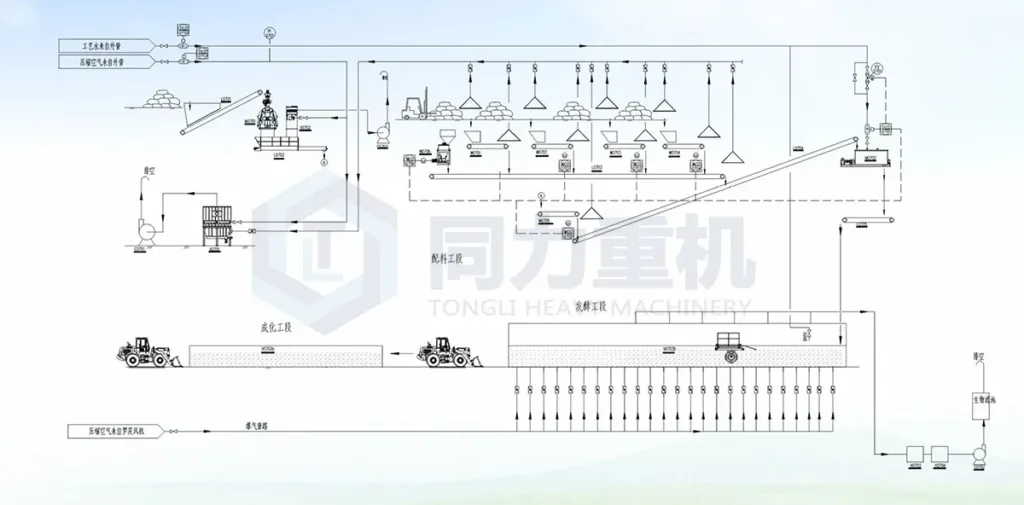

The manner starts offevolved with the selection and instruction of raw substances, in which natural materials which include animal waste, agricultural residues, and sewage sludge are mixed with inorganic additives like phosphates, nitrates, and potassium compounds. This combo is critical for attaining the favored dietary balance and bodily houses inside the very last product.

Integration strategies vary, however typically involve co-granulation or blending systems that ensure uniform distribution of nutrients. The core of the procedure is the granulation level, where uncooked materials undergo mechanical or chemical transformations to shape granules. This degree is critical for figuring out the nutrient release profile and bodily traits of the very last product.

| method degree | Description |

|---|---|

| uncooked fabric guidance | choice and blending of natural and inorganic substances. |

| Granulation | bodily or chemical transformation of materials into granules. |

| Drying and Cooling | discount of moisture content and coaching for packaging. |

| pleasant manage | ensuring nutrient stability and safety standards are met. |

at some stage in the production line, advanced technologies including computerized dosing structures and actual-time best tracking structures are employed to optimize the production waft and ensure product consistency. Tongli is committed to incorporating environmentally sustainable practices, which include waste discount and electricity-efficient systems, to reduce the environmental effect of our manufacturing methods.

Key Equipment Used in Organic-Inorganic Fertilizer Production Lines

The success of an natural-inorganic compound fertilizer manufacturing line largely depends at the efficiency and reliability of its device. Tongli guarantees the incorporation of superior and strong equipment to facilitate the seamless integration and processing of raw materials.

one of the central portions of system in this manufacturing line is the Rotary Drum Granulator. This system is pivotal for blending the natural and inorganic substances uniformly and producing granules with the preferred properties. Its high-potential layout and adjustable rotational pace make it ideal for coping with distinct forms of substances and formulations.

some other crucial piece of gadget is the Vertical Chain Crusher. This crusher is used for crushing lumpy substances into smaller sizes, that’s essential for regular mixing and granulation. The crusher’s layout makes a speciality of minimizing dirt and noise, which complements the operational environment and protection.

The Batching gadget is crucial for precise aspect measurements. It employs superior weighing and meting out generation to make sure that the proportions of organic to inorganic substances are correct, thereby keeping the satisfactory of the final product.

For the drying and cooling of fertilizer granules, the Rotary Dryer and Cooler are vital. These units are tailored to lessen the moisture content material of the granules and produce down their temperature, that’s critical for preserving the integrity of the granules and preventing caking.

The entire line is supported by using a brand new manipulate machine, which video display units and adjusts the manufacturing parameters. This gadget ensures that each phase of the manufacturing procedure is optimized for efficiency and exceptional, adhering to the stringent requirements set by way of regulatory our bodies.

Steps for Integrating Organic and Inorganic Materials in Fertilizer Manufacturing

The technique of integrating organic and inorganic materials into a cohesive fertilizer product entails specific fabric dealing with, blending, and granulation strategies. The aim is to attain a balanced nutrient profile that complements each the effectiveness and applicability of the fertilizer.

fabric preparation and Pre-remedy

first of all, natural substances such as compost, manure, and agricultural waste are subjected to a sequence of pre-remedy steps along with screening, crushing, and homogenizing to make sure uniform particle sizes and compositions. Concurrently, inorganic components, generally phosphates, nitrates, and potassium salts, are exactly measured and prepared for integration.

mixing system

The center of the integration process lies within the mixing level, in which natural and inorganic materials are combined. This is commonly finished in a horizontal mixer or a pug mill, in which materials are mixed to ensure a homogeneous combination. Manipulate structures screen the integration time and intensity to optimize the nutrient distribution and save you segregation of components.

Granulation

Following blending, the homogeneous cloth undergoes granulation, a vital step for enhancing the bodily houses of the fertilizer. The granulation technique may be finished through extrusion, drum granulation, or pan granulation strategies, depending at the favored size and texture of the final product.

Conditioning and Drying

submit-granulation, the product is conditioned to obtain the preferred moisture content material and hardness, regularly through the addition of binders or moisture agents. The granules are then dried to lessen moisture content material, which guarantees stability and durability of the fertilizer granules throughout garage and application.

nice manipulate

for the duration of the producing method, rigorous first-class control measures are applied to make certain that the very last product meets strict standards of nutrient content and physical integrity. Samples are regularly examined in on-website online laboratories for nutrient composition, solubility, and particle length distribution.

| method Step | equipment Used | Key manipulate Parameters |

|---|---|---|

| fabric education | Crushers, Screeners | Particle length, Homogeneity |

| mixing | Horizontal Mixers, Pug generators | blending Time, intensity |

| Granulation | Drum Granulators, Extruders | Granule length, Moisture content material |

| Conditioning | Conditioners | Moisture content, Binder Addition |

| high-quality control | Laboratory device | Nutrient evaluation, Solubility checks |

Quality Control and Safety Measures in Fertilizer Production

in the realm of organic-inorganic compound fertilizer manufacturing, keeping stringent high-quality control and sturdy safety measures is paramount. At Tongli, our dedication to those requirements ensures the reliability and safety of our fertilizers, while also adhering to environmental policies.

Implementation of fine manage Protocols

We employ a complete collection of high-quality control tests during the production system. This begins with the rigorous testing of raw materials to affirm their compatibility and protection. Continuous tracking and trying out occur at every stage of manufacturing to make sure that the final product meets the perfect chemical composition required for powerful fertilization.

safety Measures inside the production Line

protection is a critical situation within the managing and production of fertilizers, specifically while integrating organic and inorganic components. Our facilities are prepared with advanced protection systems, including emergency shutdown mechanisms and ventilation systems designed to handle doubtlessly risky emissions. Regular protection drills and education classes are obligatory for all personnel to mitigate risks related to the managing of chemical materials.

Regulatory Compliance and Environmental Stewardship

Compliance with local and global regulatory standards isn’t pretty much adhering to legal requirements however also approximately ensuring the safety and properly-being of our community and the surroundings. We engage in routine audits and certifications to stay ahead of enterprise requirements, applying environmentally pleasant practices in waste control and emissions manipulate to decrease our ecological footprint.

Future Trends and Technologies in Fertilizer Production Systems

The landscape of fertilizer production is constantly evolving, driven with the aid of advances in generation and a growing emphasis on sustainability. Inside the realm of organic-inorganic compound fertilizer production, numerous modern trends and technology are poised to decorate efficiency and environmental friendliness.

| trend/generation | Description | effect |

|---|---|---|

| clever production structures | Integration of IoT and AI to optimize manufacturing strategies. | increases production performance and decreases waste. |

| Nanotechnology | Use of nano-encapsulated nutrients for sluggish-release fertilizers. | Improves nutrient uptake with the aid of vegetation and minimizes environmental runoff. |

| Biostimulants | Incorporation of herbal substances or microorganisms that enhance plant boom. | complements soil fertility and plant resilience against abiotic strain. |

| Recycling Waste substances | using commercial and agricultural waste as uncooked substances in fertilizer manufacturing. | helps round economy models and reduces dependency on virgin substances. |

searching beforehand, the natural-inorganic compound fertilizer zone will probably witness extended adoption of precision agriculture practices. This includes the use of facts analytics gear to expect the top of the line nutrient necessities and alertness timings for vegetation, thereby ensuring that fertilizers are used more judiciously.

additionally, regulatory frameworks and sustainability tasks are expected to form the improvement of latest fertilizer products. Corporations like Tongli Heavy machinery, recognised for his or her sturdy machinery in organic-inorganic compound fertilizer production lines, are at the leading edge of adopting these new technology to fulfill each marketplace needs and environmental regulations.

In conclusion, the future of fertilizer manufacturing is geared toward technology that not handiest enhance productiveness but additionally address ecological concerns. This ensures that as the global populace grows, agricultural practices can remain sustainable and efficient.