Introduction to Micropelletizing

What is micro-granulation? Microparticle granulation is the process of aggregating fine granular materials into small particles. Microparticulation produces smaller particles, typically in the range of 20-60 mesh, than conventional granulation methods. This technology can be realized with a pin mixer alone or a pin mixer in combination with a disc granulator. When full-scale pelletizing is not required, or only smaller particles are needed, micropelletizing with pin mixers is a cost-effective alternative.

Advantages of Microparticulation

Why Microgranulation? The main purpose of micro-granulation is to make fine materials easier to handle, transport and use. It improves product performance, reduces dust loss, prepares material for landfill, and reduces other problems associated with dust. Key benefits of microparticle granulation include.

- Significant suppression or elimination of dust. This can be beneficial in many situations, such as preventing wind dispersion of landfill material, reducing dust escape during processing, reducing equipment damage and safety hazards, and reducing raw material waste.

- Improve material handling and transportation. After granulation, the materials are easier to handle and transport, and less likely to generate dust or be blown away by the wind.

- Improvement of application and utilization effect. In agriculture, for example, granulated soil amendments offer a number of advantages: more precise and reliable application, more predictable results, faster nutrient decomposition, less visual impact, etc.

Almost any material in powder form can benefit from micronization. Commonly pelletized materials include pigments and dyes, carbon black, coal dust, fly ash, specialty powders, filtration media and catalysts.

Microparticle granulation in needle mixers

Although microparticle granulation can be performed in a variety of equipment, it is most effective in needle mixers. Needle mixers have become the industry standard for microparticle granulation, providing the ideal solution for agglomerating fine materials into microparticles. As a result, needle mixers have been widely used in the coal and carbon black industries for decades.

Advantages of Needle Mixers

High-speed rotary action: Needle mixers utilize a high-speed rotary action that not only thoroughly mixes the liquid and solid feeds, but also begins to agglomerate the fines of the material to create small, dense particles.

Highly efficient mixing: Needle mixers are able to achieve highly efficient mixing and agglomeration in a short period of time, making them suitable for continuous production.

Flexibility: The Needle Mixer can be used as a continuous stand-alone unit to quickly and reliably generate microparticles in a process setup, but can also be used in conjunction with other equipment (e.g. disc granulators) to further optimize particle characteristics.

Typical Microparticle Granulation Process

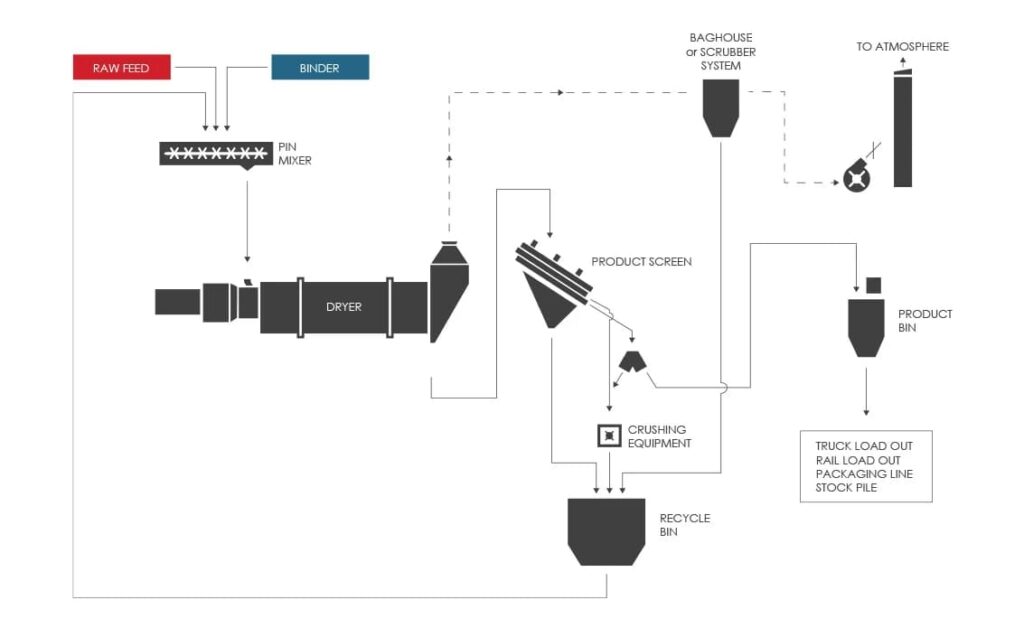

- Feed and Binder Addition: The raw material is fed into the needle mixer at a continuous rate, while the binder injection system injects the binder into the needle mixer at a continuous specified rate.

- Mixing and Agglomeration: The material and binder are thoroughly mixed in the needle mixer and begin to agglomerate, forming microparticles as the mixture moves through the length of the needle mixer.

- Further Agglomeration (optional): At this point, if desired, the pellets can be further grown and/or rounded using a disc agglomerator. In this case, the needle mixer prepares the pellets for optimized pellet formation on the discs and reaches the target humidity level prior to the disc granulator, thereby increasing productivity and reducing the amount of binder required, since densification is carried out by movement in the needle mixer, rather than with additional binder in the disc granulator.

- Drying: Once the pellet formation is complete, the micro-pellets are usually discharged from the needle mixer and fed through a conveyor into a rotary dryer to reduce the moisture content of the pellets to the desired level. Here, the pellets are tumbled in a rotating drum, and a flyer picks up the material and drops it into the process gas stream, maximizing heat transfer efficiency. In this case, the fluidized bed dryer is also an industrial drying option.

- Post-processing: The pellets are discharged from the dryer and sent via conveyor to the next processing step (sieving), storage or packaging. In some cases, it is also beneficial to cool the material prior to packaging or storage. Similar to drying, this can be done in a rotary cooler or a fluidized bed cooler.

In summary, needle mixers offer an efficient, flexible and cost-effective solution for microparticle agglomeration that meets the needs of a wide range of industries. When only coarse agglomeration is required, microparticle granulation using a needle mixer alone is a more cost-effective alternative to full-scale disc granulation or granulation drum operations.

What factors need to be considered in the selection of a microparticulation plant?

There are several key factors to consider when selecting a microparticulation plant.

- Raw material characteristics: Different raw materials have different requirements for equipment. For example, finely powdered materials are often suitable for pin mixers because of their ability to effectively mix and initially agglomerate fine particles.

- Target product size: For smaller sizes of micropellets, a pin mixer may be more appropriate; for larger sizes of pellets, a disc pelletizer is a common choice.

- Size of production: For small scale production, a pin mixer alone may be considered, while large scale production may require a pin mixer in combination with a disk pelletizer.

- Fuel type: If gas fuel is used, a shaft furnace may be an option. However, the adaptability of the vertical furnace to the raw material is poor, and the scale of a single furnace is difficult to large-scale.

- Environmental requirements: The belt roaster process is cleaner and more environmentally friendly than other methods, and meets the requirements of cleaner production and ultra-low emissions in the iron and steel industry.

- Investment cost: shaft furnace equipment is simple, less investment, but limited capacity. The initial investment of belt roaster is larger, but it has more advantages in large-scale production.

- Adaptability of raw materials: The belt roaster has better adaptability to raw materials and can handle many types of iron ore powder.

- Automation level: belt roaster process flow is compact, centralized equipment, more conducive to the realization of intelligent control.

In summary, according to the specific production needs, raw material characteristics, scale, cost and other factors to consider, choose the most suitable particulate granulation equipment. For large-scale production with high environmental requirements, belt roaster is a better choice.

TONGLI has been a leader in the field of granulation technology and equipment since 1958. We have the materials experience and process knowledge to provide the best pelletizing solution for your processing needs. In addition, our Innovation Center offers comprehensive testing capabilities. For more information about our pelletizing systems, contact us today.