Guide to Fertilizer Dryers

Fertilizer drying is a critical part of agricultural production. By removing water from fertilizers, you can improve the storage stability of fertilizers, extend shelf life, and improve fertilizer application. This article will discuss in depth the types of fertilizer dryers, working principle, advantages and applications in agricultural production, to help you choose the most suitable drying equipment.

Types and characteristics of fertilizer dryer

Fertilizer dryer is mainly divided into the following types according to the different working principles:

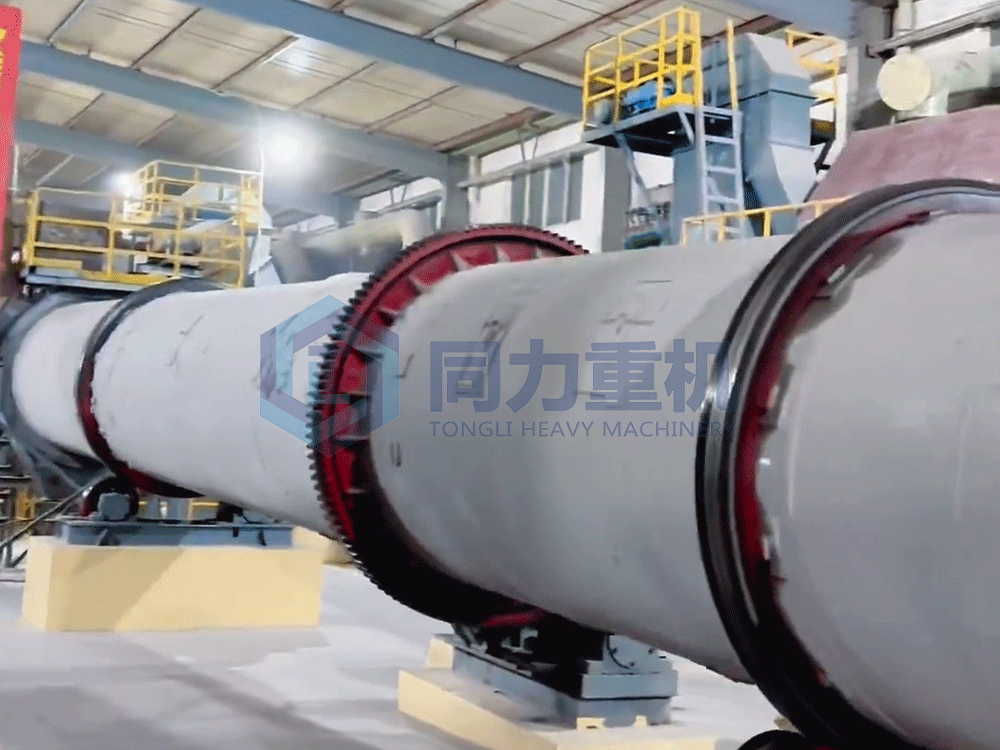

- Rotary drum dryer: It is a traditional drying method, which realizes drying by rotating the cylinder to fully contact the material with hot air. It is suitable for drying large quantity and granular materials.

- Fluid bed dryer: the material will be suspended through the airflow, so that the material and the hot air to fully contact, to achieve rapid drying. Suitable for fine particles, sensitive to the drying temperature of the material.

- Jet bed dryer: spray the material into the high temperature airflow to realize instant drying. It is suitable for materials with high requirements for drying time and easy to oxidize and deteriorate.

- Flash dryer: instantly disperses the material into the high temperature airflow to realize rapid drying. Applicable to the drying of heat-sensitive materials.

- Stirring dryer: mix the material with hot air through mechanical stirring to realize drying. Suitable for drying viscous and pasty materials.

| Drying Machine Type | Common Applications | Advantages | Disadvantages |

|---|---|---|---|

| Rotary Drum Dryer | Large-scale granular fertilizers | High capacity, durable | High energy consumption |

| Fluid Bed Dryer | Powder and granular forms | Rapid drying, uniform heating | Requires fine particle size |

| Spray Dryer | Organic and sensitive fertilizers | High energy efficiency, low dust | Limited to small batches |

| Flash Dryer | Rapid moisture removal needs | Quick processing, high thermal efficiency | May lead to thermal degradation |

| Agitated Dryer | Viscous or sludgy materials | Effective for difficult materials | Complex maintenance |

Understanding the specific application and operational requirements is critical in selecting the right fertilizer dryer. Each type offers unique advantages and may be better suited to different environments and production needs.

Advantages of Fertilizer Dryer

- Improve the quality of fertilizer: By removing the water, it can improve the uniformity, fluidity and nutrient content of the fertilizer, so as to improve the effect of fertilizer application.

- Extend the storage period of fertilizer: the dried fertilizer is not easy to caking, deterioration, can be stored for a long time.

- Improve production efficiency: Drying equipment with high degree of automation can greatly improve production efficiency and reduce labor intensity.

- Flexibility: A wide range of fertilizer types and forms can be processed. Including granular, powder and liquid form.

- Improve environmental protection: modern drying equipment using efficient heat recovery system, can reduce energy consumption, reduce environmental pollution.

Advantages of rotary drum dryers in NPK fertilizer production

As the key equipment for NPK compound fertilizer production, rotary drum dryer has the following advantages.

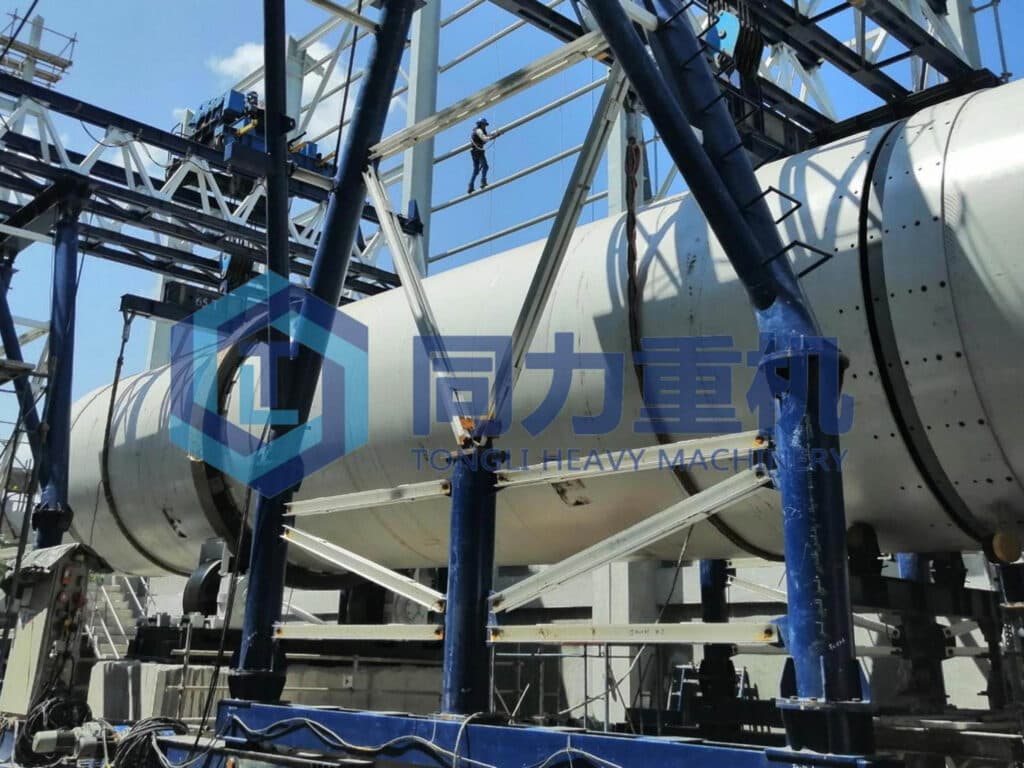

1. Widely used in large-scale compound fertilizer production line

Rotary drum dryer can meet the demand of large capacity, widely used in large-scale NPK compound fertilizer production line.

2. Improve the drying and curing degree of fertilizer particles.

The high temperature steam in the drum can effectively dry the fertilizer particles and improve the dryness and curing degree of the finished products.

3. Applicable to the production of a variety of compound fertilizer products

Rotary drum dryer can be used to produce DAP, MAP, ammonium sulfate, TSP, SSP, urea and other NPK compound fertilizer products.

4. A small amount of phosphoric acid and ammonia can be added in the agglomeration process.

In the process of rotary drum agglomeration, a small amount of phosphoric acid and ammonia can be added appropriately to improve the conditions of agglomeration and increase the efficiency of agglomeration.

5. Production process without environmental pollution

Rotary drum agglomeration process does not have environmental pollution problems, in line with the requirements of environmental protection. In short, rotary drum dryer as a key equipment for the production of NPK compound fertilizer, to improve production efficiency, product quality and environmental protection plays an important role, is one of the first choice of compound fertilizer industry equipment.

How to choose the right type of fertilizer dryer for your needs?

When choosing the right type of fertilizer dryer for your needs, there are several key factors to consider to ensure that the equipment will meet specific production requirements and economic benefits. Below are a few important points to consider:

1. Drying method

Drying equipment is mainly categorized into two types: batch drying and continuous drying. Batch drying is suitable for small batch production while continuous drying is suitable for large scale production. According to the scale of production and demand to choose the appropriate drying method is the first step.

2. Material Characteristics

Different materials have different physical and chemical properties, which will affect the choice of drying process. For example, fluidized drying is suitable for bulk materials and can provide uniform drying results. Understanding the characteristics of the material to be dried (e.g., particle size, moisture content, etc.) is critical to selecting the right dryer.

3. Energy efficiency

Drying processes are often energy intensive, so choosing a dryer with high thermal efficiency can significantly reduce operating costs. The thermal efficiency of dryers usually ranges from 15% to 80%, and the selection should focus on the energy consumption index of the equipment.

4. Operating costs and reliability

In addition to the initial investment, long-term operating costs are also an important consideration. Selecting a dryer that is easy to maintain and has a low failure rate can reduce subsequent maintenance and operating costs.

5. Environment and regulations

Local environmental regulations and noise pollution limits also need to be considered when selecting drying equipment. These factors may affect the choice of equipment, especially in production environments near cities or residential areas.

6. Production capacity

Determining the required drying capacity according to the production demand is the key to selecting equipment. The output of the equipment should match the production schedule to avoid waste of resources or production bottlenecks.

7. Supplier and technical support

Choose reputable suppliers and make sure they can provide the necessary technical support and after-sales service. Understanding the technical parameters of different equipment and user feedback will also help you make an informed choice. Considering the above factors together can help you choose the type of fertilizer dryer that best suits your needs.

The importance of temperature control in fertilizer drying efficiency?

The importance of temperature control in fertilizer drying efficiency

In the process of fertilizer drying, temperature control is a very critical factor. Reasonable temperature control can not only improve the drying efficiency, but also ensure the quality of fertilizer. The following is the importance of temperature control in fertilizer drying:

1. Protection of nutrients

Drying temperature is too high will lead to fertilizer nitrogen, phosphorus, potassium and other nutrients are decomposed or volatilized, thus reducing the effectiveness of fertilizer. In general, the material drying temperature should not be higher than 60 ℃, and the hot air temperature in contact with the material should also be controlled within 130 ℃.

2. Retain the effective bacterial flora

For organic fertilizer containing a large number of active strains of bacteria, the drying temperature is too high will lead to the death of effective flora. To avoid this, the drying temperature should be controlled at 50-60 ℃.

3. Improve drying uniformity

The precision of temperature control directly affects the uniformity of drying. Different materials need to be dried at a specific temperature, too high or too low temperature may lead to poor drying results. Precise control of temperature helps to improve the uniformity of drying.

4. Reduce energy consumption

Reasonable control of drying temperature can improve the efficiency of heat utilization, thus reducing energy consumption. Generally speaking, a dryer with a thermal efficiency between 15-80% can provide higher energy utilization.

5. Improvement of physical properties

The free moisture content in fertilizers directly affects their physical properties. Excessive moisture not only reduces the effective nutrient content, but also seriously affects the physical properties such as fluidity of the fertilizer. Precise control of the drying temperature helps to achieve the optimum moisture content.

In short, in the process of fertilizer drying, reasonable control of temperature is the key to improve drying efficiency and ensure the quality of fertilizer. By adopting advanced temperature control technology, such as installing temperature sensors near the heat exchange point and adopting frequency converter to accurately regulate the air volume, etc., the precise control of drying temperature can be realized.

How to ensure the temperature control precision of the dryer?

Ensuring the temperature control accuracy of the dryer is the key to improve the drying efficiency and product quality. The following are some effective methods and strategies:

1. Use high-precision temperature controller

Choosing a dryer equipped with a high-precision temperature control device can realize precise control of the temperature inside the drying room. For example, the temperature controllers of some modern dryers are able to achieve a measurement accuracy of ±0.1℃, which is especially important for temperature-sensitive materials.

2. Regular calibration of equipment

Regular calibration of temperature sensors and control systems ensures their accuracy. Calibration can help identify and correct any potential deviations, thus maintaining the stability of temperature control.

3. Optimize hot air circulation

By designing a proper hot air circulation system, you can ensure that the temperature in the drying room is evenly distributed and avoid localized overheating or overcooling. This helps to improve the drying effect and the precision of temperature control.

4. Implementation of automatic control system

The use of automated control systems can monitor temperature changes in real time and automatically adjust the heating and fan operation according to the set value. Such a system can respond quickly to temperature fluctuations and maintain a stable drying environment.

5. Choosing the right material and design

The material and design of the dryer will also affect the precision of temperature control. Choosing good insulation materials and reasonable structural design can reduce heat loss and improve the efficiency of temperature control.

6. Conduct temperature monitoring and data analysis

During the drying process, temperature monitoring equipment is used to record temperature change data and analyze it. Through data analysis, problems in temperature control can be identified and adjusted accordingly. Through the above measures, the temperature control precision of the dryer can be effectively improved, thus enhancing the drying efficiency and product quality.

How to extend the service life of the dryer?

Maintenance tips to extend the service life of fertilizer dryer mainly include the following aspects:

1. Regular inspection and cleaning

- Check the connecting parts: regularly check whether the connecting bolts of each part of the unit are tight, and make sure that the elasticity of the transmission belt is appropriate, so as to avoid unstable operation caused by loosening.

- Clean up the internal debris: open the observation window of the dryer regularly to clean up the debris in the cylinder, especially after a long period of non-use, so as not to affect the drying efficiency and equipment performance.

2. Maintain a good working environment

Dry and ventilated: keep the environment around the dryer dry and ventilated to avoid the corrosion of moisture on electrical parts and reduce the risk of short circuit. There should not be piles of debris around to avoid blocking the air inlet and outlet.

3. Regular lubrication

Lubrication maintenance: Regular lubrication of rollers and bearings is generally recommended once a week. Make sure all moving parts are properly lubricated to minimize wear and tear.

4. Monitor power supply and operating conditions

Stabilize power supply: Ensure long-term voltage stability of the power supply line to avoid damage to the equipment due to voltage fluctuations. During operation, the drying temperature and time should be set before starting the machine to ensure safety.

5. Regular maintenance and overhaul

- Regular maintenance: according to the frequency of use, make a regular maintenance plan, check the operating status of the equipment, find and solve potential problems in time to avoid small problems evolving into big failures.

- Clean up the furnace chamber: After the daily work, clean up the waste slag inside the furnace chamber to prevent the slag from being too thick, which affects the heat exchange efficiency and equipment operation.

- Through the above maintenance measures, you can effectively extend the service life of the fertilizer dryer and ensure its efficient and stable operation.

Fertilizer Machinery Manufacturer Recommendation

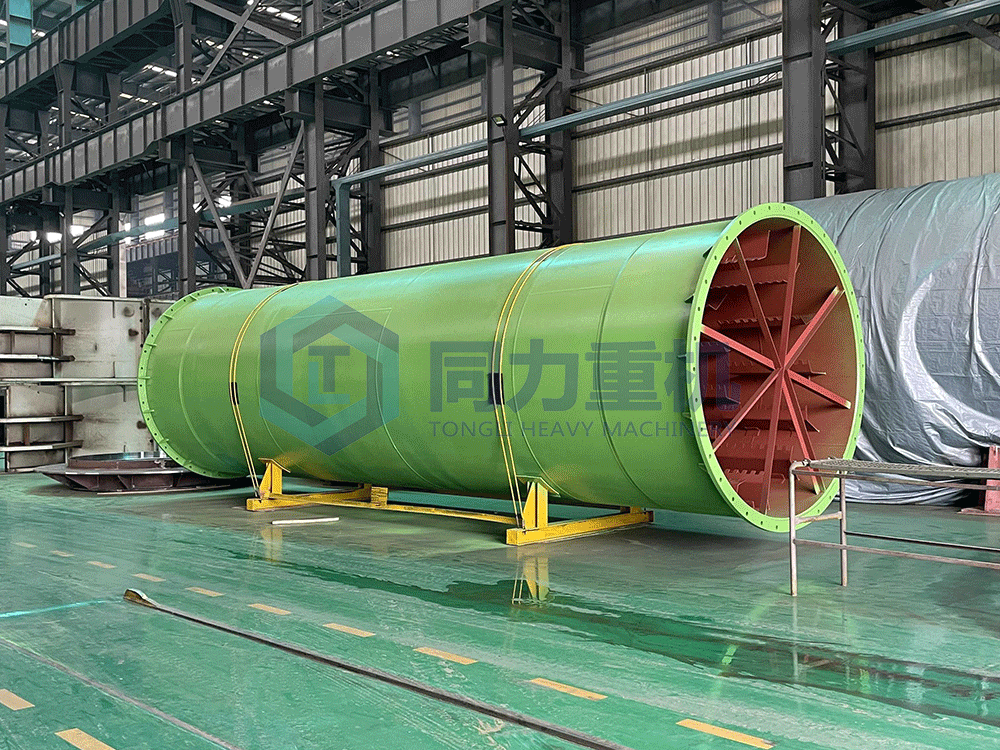

TONGLI, as a professional Fertilizer Machinery manufacturer and reliable Organic Fertilizer Plant exporter, is committed to providing customers with high quality Fertilizer Production Equipment.

With the tenet of “High Quality, Reasonable Price and Careful Service”, we produce compound fertilizer and organic fertilizer manufacturing equipment. The staff of the design department is always committed to innovate the performance of fertilizer machines and strive to manufacture the best quality fertilizer granulators and fertilizer production lines. We are looking forward to cooperating with new and old customers and establishing friendly and cooperative relationships.

We insist on being market-oriented, focusing on our products, and centering on customer satisfaction. If you are interested in our products, please feel free to contact us. We will be happy to serve you.

We offer a wide range of fertilizer machinery:

- Cost-effective Organic Fertilizer Equipment: Rotary Dryer, Crusher, Coating Drum, Disc Granulator and so on.

- Durable Compound Fertilizer Equipment: Dosing Machine, Vertical Chain Crusher, Rotary Drum Granulator, etc.

- Organic/bio-fertilizer production line: 20,000 tons organic fertilizer plant, 50,000 tons/year organic fertilizer production line, etc.

- Compound Fertilizer Production Line: 50,000 tons/year compound fertilizer plant, 100,000 tons/year compound fertilizer production line, etc.

Frequently Asked Questions about Fertilizer Dryer

What are the different types of fertilizer dryers?

The main types of fertilizer dryers are rotary drum dryers, fluid bed dryers, jet bed dryers, flash dryers and stirring dryers. Each type is tailored to specific needs and offers different benefits depending on the material and size of the operation.

How does a rotary drum dryer work?

Rotary drum dryers direct airflow and evaporate water by rotating a cylinder, making them ideal for large-scale operations and drying a variety of fertilizer formulations.

What are the advantages of using a fluid bed dryer?

Fluid bed dryers utilize perforated plates to generate a stream of hot air that quickly suspends and dries fertilizer pellets. This method provides uniform heat distribution and is ideal for temperature sensitive fertilizer types.

Which dryer type is recommended for energy efficiency?

Jetbed dryers are recommended for their high energy efficiency and are suitable for drying organic and fine-grained fertilizers, minimizing dust and product loss.

What should I consider when selecting a fertilizer dryer?

When selecting a fertilizer dryer, consider the type of fertilizer, size of operation, energy efficiency, and specific drying needs. It is critical to select a dryer that matches your agricultural needs to optimize productivity.

Can modern fertilizer dryers handle different types of fertilizer?

Yes, modern fertilizer dryers are very flexible and can handle all forms of fertilizers, including granules, powders and liquids, thanks to their advanced automated moisture control systems and dust protection mechanisms.

What are the benefits of automated humidity control in a fertilizer dryer?

Automated humidity control systems in fertilizer dryers use sensors to monitor and adjust the humidity content during the drying process. This ensures optimal drying results and maintains the chemical integrity of the fertilizer.

How do advanced features in fertilizer dryers improve safety and efficiency?

Modern fertilizer dryers are equipped with features such as heat recovery systems and smart technology that improve safety, reduce energy consumption and increase the overall efficiency of the drying process.

How do I perform maintenance to extend the life of my fertilizer dryer?

Regular cleaning, lubrication of moving parts, timely replacement of wear parts and calibration of system controls are key to maintaining the efficiency and extending the life of your fertilizer dryer.

What is the importance of controlling temperature in the fertilizer drying process?

Effective temperature control is essential to optimize the drying process, improve dehumidification efficiency and ensure the structural integrity of the fertilizer pellets, while preventing potential safety hazards.