DCS control system for ammonia granulating compound fertilizer production equipment

1. Characteristics of ammonia nitrate fertilizer DCS system:

- With the rapid development of computer technology, the functions and structures of PLC have been rapidly improved. It is no longer just a simple function of logic control, and its application scope has developed to continuous and decentralized process control. Small and medium-sized DCS systems based on PLC, industrial Ethernet, computers, and configuration software have gradually replaced the high-cost, high-maintenance pure DCS in low- and medium-sized applications with the characteristics of low cost, high-performance, multi-function, and low-maintenance. Control System.

- As a professional automation company, Siemens’ S7-300/400 series PLC integrates most of the functions of DCS. It has the complex data processing and loop adjustment functions of traditional DCS, plus the PLC-based PLC composed of WINCC configuration software. The DCS control system is favored by domestic automation companies and users. Based on the above reasons, this solution is the first choice to use Siemens S7-300 PLC plus WINCC to form a highly reliable and low-cost DCS control system.

2. What is a fertilizer plant DCS control system(digital control system)?

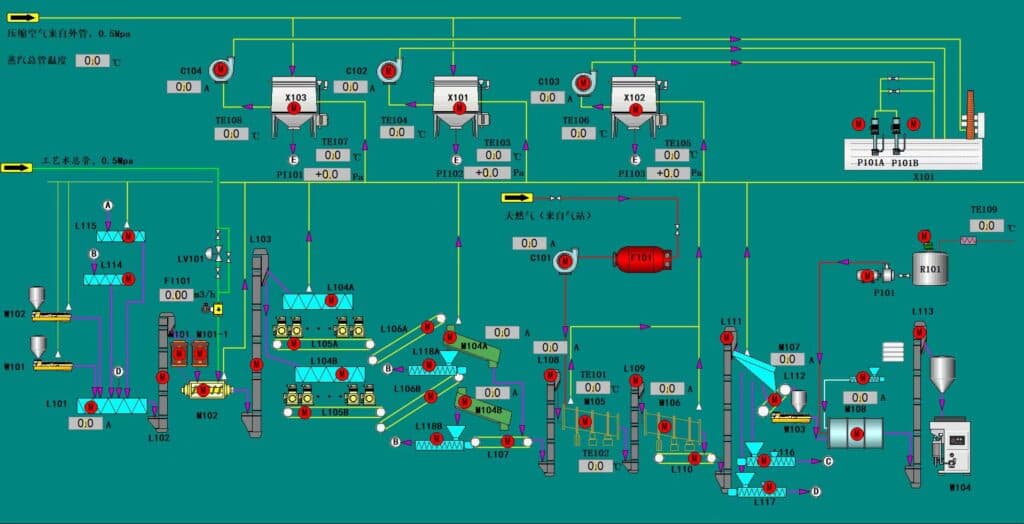

The compound fertilizer control system adopts a distributed structure, with multiple on-site control stations distributed on an open redundant communication network. Each on-site control station will be flexibly configured according to the requirements of the process equipment and the process location. On-site control The station completes continuous, discrete, sequential control and data acquisition functions through intelligent process I/O hardware, connection terminals, and necessary signal processing. This system consists of a host computer monitoring system, a DCS master station, an on-site control station, and a data communication network.

3. Compound fertilizer production line computer monitoring system:

The computer monitoring system of the compound fertilizer production line is set up in the central control room and consists of an engineer station and an operator station. The engineering station mainly completes software preparation, program downloading, system configuration, system maintenance, and authorization management. The operator station mainly completes the operator’s monitoring and control of production equipment.

Operator station

- The task of the operator station is to collect and display relevant operating information on standard screens and user configuration screens so that operators can monitor and control the operating conditions of the unit.

- Each operator station has its division of labor, but any display and control functions can be completed on any operator station.

- LCD specifications: 19, pixels 1280×1024, equipped with keyboard, mouse or trackball.

- CPU: 32-bit frequency ≥3.0GHz, hard disk ≥80G, memory ≥1G

- The number of keystrokes required to call up any screen is no more than three.

- With the trend curve recording function,

- Has production report, event report, alarm report, and other functions,

- The communication rate between the operation station and the on-site control station>10Mbit/sec,

- Flowchart status update, screen switching, or refresh time is less than 1.5 seconds (including dynamic and static data)

- Power supply: 220V AC±15%, 50Hz.

Engineer workbench

- The engineer workbench in DCS provides a set of engineer workstations for program development, system diagnosis, control system configuration, database, and screen editing and modification. The engineer’s workstation is also equipped with other relevant external equipment.

- The engineering workstation can call up any defined system display screen, and any screen and trend chart generated on the engineering station can be loaded to the operator station through the communication bus.

- The engineering station can not only call out the system configuration information and related data of any processing unit (DPU or CPU) in the system through the communication bus but also download the configuration data from the engineering station to each distributed processing unit and operation member station. In addition, the system should automatically refresh its memory when new configuration data is confirmed.

- The engineering station includes the station processor, graphics processor, and the main memory and peripheral devices required to accommodate all databases, various display and configuration programs in the system. A historical trend buffer required for system trend display is also provided.

DCS main station/workbench:

The DCS main station is placed in the main control room. The main station is composed of Siemens S7-315-2DP (multiple blocks can be configured according to the actual situation), high-speed Ethernet modules, power supplies, I/O components, etc. It will be mainly used for computer monitoring and control. System data exchange, execution program, unified coordination of data collection, instruction execution, communication, and other tasks of each field station.

On-site control cabinet station:

The on-site control station mainly completes the collection of on-site analog and switching signals, the sequential starting and stopping of process equipment, the adjustment of process parameters, and the automatic adjustment of parameter control loops. This system is composed of an S7-300 series CPU and digital input and output modules, analog input and output modules, remote I/O modules, Ethernet communication, and other modules.

Communication network:

The monitoring system in the central control room and the field control station use the industrial Ethernet network for communication, and the field stations use the PROFIBUS network for communication.

What is the I/O module of the ammonia chloride fertilizer plant DCS control system?

Digital input module (DI):

- Passive input: Power is provided internally by the DCS system (24V.DC)

Digital output module (DO):

- The output signals are provided through the intermediate relay installed in the cabinet. The DO signals sent are all continuous. The output relay contacts are all normally open passive contacts. The output contact capacity is not less than 220V.AC 5A.

Analog input module (AI):

- The 4~20mA DC system can provide a 24V DC power supply for 4~20mA two-wire transmitters; the system can also provide a 24V DC power supply for 4~20mA three-wire instruments.

- For 4~20mA DC input signal, the maximum input impedance is 500Ω and can directly accept three-wire thermal resistance (Pt100) input.

- Can directly accept thermocouple signals. The linearization of thermocouples in the entire working section is completed in the process station without going through the data communication bus.

Analog output module (AO):

- •The module can output a 4~20mA DC signal and has a load capacity of driving circuit impedance greater than 600Ω.

4. Main functions of the ammonia nitrate fertilizer plant DCS

- Each motor implements chain control according to process requirements;

- The parameters of each process section (the specific number is determined by the process) are entered into the central control system for online monitoring and automatic control;

- The analog signals of the operating values of each process parameter can respectively establish set values, alarm values, and safety values according to process requirements so that the process parameters can be automatically run in strict accordance with the pre-entered set values. When the preset alarm value is reached due to special circumstances, the system will send out audible and visual alarm signals to promptly remind the operator to deal with it, which can effectively improve the product qualification rate. When the operating value of the process parameters exceeds the safe value, the system sends a fault shutdown signal, which can effectively avoid the occurrence of quality and safety accidents, and the operator can easily modify the process parameters;

- Control the raw material batching according to the process requirements. When using it, you only need to set the hourly output and the formulas of various raw materials. The system can automatically adjust the set output of each batching scale participating in the batching, and adjust the batching scale according to the set output. Instantaneous flow rate makes the ratio of raw materials meet the formula requirements. During actual production, recipe records, production reports, and operating curves can be generated for future viewing and statistics;

- Depending on the operating status of each motor, the running, stopped, fault and other statuses can be displayed in real-time on the computer screen according to color. The operating status of each piece of equipment is clear at a glance;

- Operators and engineers design different passwords to limit their respective permissions. Engineers can modify the control mode and key process parameters, while operators can only modify superficial operating parameters that are authorized to be modified, thus avoiding the consequences of human error;

- important analog quantities have trend charts and trend analysis, can make early warning processing, review, and store historical data, and have power-down protection functions. The analysis of historical trend charts can assist the management department in managing the entire production process and can provide data support for future improvements in production technology and production processes.

- A projector can be connected to enlarge the monitoring system process.

5. Ammonia Fertilizer Plant DCS Interlock control function:

- This system includes 1-7# batching scales, proportional control between scales, frequency conversion adjustment of each scale, and the system has a shortage of material, overfeed alarm, and automatic correction functions;

- 1-7# batching scale and dilute sulfuric acid flow signal proportional control, dilute acid pump frequency adjustment, system design corresponding operation interface;

- 1-7# batching scale and urine flow signal proportional control, urine pump frequency adjustment, system design corresponding operation interface;

- The urea scale and the water flow meter form a self-contained system with proportional control and a corresponding operating interface designed for the system;

- The finished product scale (not equipped) is temporarily designed with a constant speed flow display, retaining the proportional control interface of the finished product the oil volume of the coated oil pump, and the frequency conversion speed of the dusting spiral.

- Display the temperature value interface of the inlet and outlet of dryers 1# and 2#.

- The system screen requires the design of a process flow chart for this device to facilitate operation.

6. DCS system monitoring and control parameter table

| Item | Parameter Type |

|---|---|

| Ammonium chloride belt scale | detection, control |

| Ammonium phosphate belt scale | detection, control |

| Potassium chloride belt scale | detection, control |

| Urea belt scale | detection, control |

| Stick powder belt scale | detection, control |

| Mixed acid flow | detection, control |

| Sulfuric acid flow | detection, control |

| Ammonium phosphate solution flow | detection, control |

| Tank reactor A temperature | Detection |

| Tank reactor B temperature | Detection |

| Ammonium phosphate dissolving tank A temperature | Detection |

| Ammonium phosphate dissolving tank B temperature | Detection |

| Washing fluid flow | detection, control |

| Granulator gas ammonia pressure | Detection |

| Granulator gas ammonia flow rate | detection, control |

| Hot air stove A temperature | Detection |

| Dryer A inlet temperature | Detection |

| Dryer A outlet temperature | Detection |

| Dryer A outlet pressure | Detection |

| Hot air stove B temperature | Detection |

| Dryer B inlet temperature | Detection |

| Dryer B outlet temperature | Detection |

| Dryer B outlet pressure | Detection |

| Coating tank temperature | Detection |

| Dilute acid tank sulfuric acid flow rate | detection, control |

| Dilute acid tank water flow | detection, control |

| Washing liquid circulation pump A pressure | Detection |

| Washing liquid circulation pump B pressure | Detection |

Conclusion:

As compound fertilizer plants become more and more automated in recent years, the requirements for central control system capabilities are also increasing. Tongli has developed advanced DCS technology and applied it to ammonium nitrate fertilizer plants. This DCS system provides powerful process Control, real-time monitoring and automatic adjustment ensure the safety of employees and improve the quality of ammonium chloride compound fertilizer finished products