The Evolving Role of Coater Technology in Fertilizer Production

In the evolving landscape of agriculture, the role of coater technology has emerged as a game-changer in fertilizer production. As the No.1 Fertilizer Production Line Solution, coaters enhance nutrient efficiency and sustainability, ensuring that every granule delivers optimal growth benefits while minimizing environmental impact.

Innovative Features of Modern Coater Systems

This article delves into the innovative features of modern coater systems, highlighting their ability to provide precise, controlled nutrient release tailored to specific crop needs. By integrating these advanced technologies, producers can significantly elevate fertilizer performance, driving both productivity and eco-friendliness in agricultural practices.

Overview of Coater Technology in Fertilizer Production

the integration of coater generation in fertilizer manufacturing traces marks a widespread development in agricultural sciences. Coaters are essential for enhancing the performance and efficacy of fertilizers thru the utility of defensive and nutrient-enhancing layers. This technology is pivotal in controlling the release of vitamins, that is vital for optimizing plant boom and minimizing environmental impact.

present day coater machines make use of today’s strategies to apply uniform coatings to granular fertilizers. Those coatings can range from easy polymers that manipulate moisture interplay, to complex nutrient layers that offer tailored nutrient launch profiles unique to the crop’s needs. The primary aim is to ensure that nutrients are to be had on the right time and within the proper amounts, consequently maximizing the fertilizer’s performance.

| feature | Description | impact on Fertilizer efficiency |

|---|---|---|

| Precision Coating application | ensures even insurance of each granule, decreasing waste. | complements nutrient availability and uptake. |

| managed launch technology | Coatings designed to dissolve or degrade beneath specific conditions. | Improves nutrient use performance and minimizes environmental runoff. |

| Customizable Coating formulation | formulation may be tailored to unique crop necessities or environmental conditions. | lets in for focused nutrition, adapting to varying agricultural wishes. |

main suppliers and manufacturers inside the industry, together with Yargus manufacturing, Inc. And Stamicarbon B., provide a variety of coater machines and technology, every designed to meet diverse agricultural needs and manufacturing scales. Those organizations constantly innovate to provide answers that now not handiest enhance the pleasant of fertilizer granules but additionally make contributions to sustainable farming practices.

Benefits of Using Coaters in Enhancing Fertilizer Efficiency

The incorporation of coating era in fertilizer manufacturing lines significantly boosts the efficiency and effectiveness of the fertilizers. Via applying a shielding layer around each fertilizer granule, coaters assist to control the release of vitamins, that is important for optimizing the nutrient uptake via plant life.

one of the key advantages of the use of coaters is their ability to reduce the leaching of nutrients into the environment. This managed-release mechanism guarantees that nutrients are available to flowers over a longer length, lowering the frequency of application wanted and as a consequence reducing hard work and aid fees.

furthermore, the usage of superior coater technology improves the physical and chemical houses of the fertilizer granules. The coatings can beautify resistance to moisture and mechanical harm at some stage in managing and garage. This outcomes in higher managing characteristics and less product loss, making the fertilization method more fee-effective and efficient.

further, modern coater structures equipped with precision utility generation make certain uniform coating of granules, which promotes steady nutrient release. This uniformity is essential for reaching balanced plant growth and maximizing yield potentials.

Key Components and Features of Effective Fertilizer Coaters

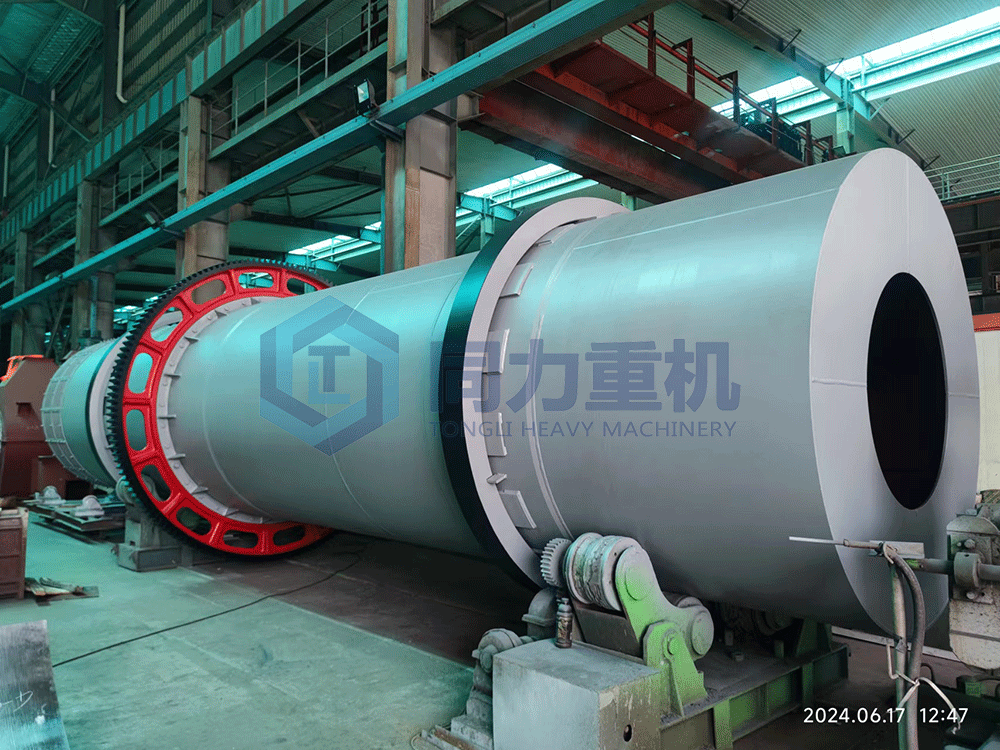

Fertilizer coaters are imperative to enhancing the overall performance and efficacy of fertilizers in agricultural programs. The center components of an effective fertilizer coater consist of the coating drum, spray device, and manage unit, every tailor-made to make certain uniform and unique software of coating substances.

The coating drum is designed to provide a consistent tumbling movement, facilitating even coverage of the granules. This is crucial in preventing agglomeration and ensuring every granule gets a uniform layer of coating fabric. The drum’s rotational speed and inner lifter layout are optimized primarily based on the traits of the fertilizer granules.

The spray machine performs a critical position in the ideal software of liquid or powdered coatings. Advanced systems are equipped with nozzles that can be adjusted for spray price and sample, allowing for first-rate control over the thickness and composition of the coating layer. This device is crucial for making use of specialized coatings which can include micronutrients, pest repellents, or water-retardant agents.

The manage unit of a fertilizer coater is typically a sophisticated piece of equipment that integrates sensors and software program to display and alter the coating manner. Real-time remarks mechanisms make sure that the application of coating materials meets predefined specifications and adapts to adjustments in environmental conditions or granule houses.

| thing | feature | features |

|---|---|---|

| Coating Drum | frivolously distributes coatings on fertilizer granules | Adjustable rotational speed, custom designed internal lifters |

| Spray gadget | Applies liquid or powdered coatings | Variable spray quotes and styles, precision nozzles |

| manipulate Unit | monitors and adjusts the coating technique | included sensors, actual-time comments, software program control |

together, those components make certain that fertilizer coaters operate efficaciously, improving the functionality and price of agricultural fertilizers. By leveraging superior technologies and precise manipulate systems, fertilizer producers can significantly enhance the high-quality in their products, contributing to greater sustainable farming practices.

Comparison of Different Coater Technologies in the Market

Coater technology play a vital position in improving the efficiency and effectiveness of fertilizer merchandise. The market offers several innovative solutions, every designed to meet unique agricultural wishes and manufacturing scales.

The Drum Coater era is broadly used due to its robust layout and capability to handle massive volumes of fertilizer. Agencies like Yargus production provide customizable drum coaters that assist various fertilizer throughput necessities, making them ideal for massive-scale operations.

some other significant era is the Fluidized bed Coater, which offers first-rate coating uniformity and efficiency. Glatt GmbH leads in this generation, offering structures that make certain precise nutrient transport through making use of a thin, even coating on each granule.

The Spouted mattress Coater stands out for its ability to coat irregularly formed particles. Batchelor technologies affords spouted mattress structures that decorate the targeted software of micronutrients and defensive agents, optimizing the discharge profiles of fertilizers.

relatively, Rotary Atomizer Coaters utilize a excessive-pace spinning disk to use coating materials, imparting fast processing times and excessive throughput. Feeco international has advanced superior rotary atomizers which are particularly powerful for water-soluble and controlled-release fertilizers.

every generation offers distinct blessings relying at the specific necessities of the fertilizer manufacturing line. Whether the concern is extent, precision, or particle form, the choice of coater era drastically influences the very last product’s quality and effectiveness.

Best Practices for Integrating Coaters into Existing Fertilizer Production Lines

Incorporating advanced coater generation into present fertilizer manufacturing traces is vital for boosting product first-rate and operational efficiency. This section outlines several nice practices which have demonstrated effective throughout the enterprise.

expertise the particular needs of your production procedure is step one toward a a success integration. Coaters designed to improve the efficiency and longevity of fertilizers need to be well matched with the present equipment to avoid disruptions and make certain seamless operations.

| Step | Description | advantage |

|---|---|---|

| 1. Assessment | conduct a radical evaluation of the current manufacturing line to identify potential integration factors. | ensures compatibility and identifies top-quality insertion factors for coaters. |

| 2. Customization | customize the coater to suit precise fertilizer formulations and preferred coating materials. | complements the effectiveness of the coating technique tailored to unique product necessities. |

| three. Automation | integrate automated manage structures to regulate the coating thickness and distribution uniformly. | Improves product consistency and reduces waste. |

| 4. Training | provide complete education for operators on the new coater technology and its upkeep. | ensures clean operation and durability of the coater implementation. |

additionally, it’s miles recommended to companion with a reputable coater supplier who can provide ongoing aid and improvements. Providers which includes Nordson company and Spraying systems Co. Are leading examples of businesses that provide sophisticated coater technologies tailor-made for the fertilizer enterprise.

in the end, continuous assessment of the coating consequences and changes based on feedback and information evaluation are essential to optimizing the coater’s performance inside the manufacturing line. This adaptive approach guarantees that the coaters not best meet the contemporary needs however also adapt to future modifications in production or marketplace necessities.