Benefits of the Granulation Drum in Granular Fertilizer Production

Fertiliser granulation is one of the most effective methods for producing multi-element granular fertilisers. This process not only significantly improves the bulk storage performance and packaging quality of fertilisers, but also greatly enhances their ease of handling and application.

Granulation drums play a crucial role in this process. At the heart of fertiliser production, the granulation drum is renowned for its reliability and robust construction. It responds flexibly to the diverse and evolving needs of the fertiliser industry, providing strong support for the production of high-quality granular fertilisers.

How to produce high quality fertiliser products with drum granulators?

Granulation drums are commonly used to agglomerate inorganic fertilisers such as NPK; nitrogen (N), phosphate (P) and potash (K) usually start as fine powders that can be granulated into an all-purpose product (known as a composite fertiliser), or they can be granulated separately and then blended together to achieve the desired nutrient formulation. Without granulation, these fine powdered materials would be dusty and difficult to handle; the denser particles would settle to the bottom of the bag or drum, causing uneven mixing (separation) and creating significant application challenges.

Also in the production of Diammonium Ammonium Phosphate (DAP) or Monoammonium Phosphate (MAP), granulation drums are used for the continuous chemical reaction associated with solid particle formation. This reaction is typically initiated in a pre-neutralisation tank, where ammonia is used to neutralise the phosphoric acid slurry while creating pellets containing phosphate and nitrogen.

In addition to developing durable and consistent granules, granulation drums can create more dynamic granular products. Different liquid binders and coatings can be used to create pellets with slow-release properties, or multi-layer pellets can be created by adding different minerals at different stages of the pelletising process.

Advantages of granulation drums

The main advantages of granulation drums include.

- Production of high quality granular fertilisers: Granulation drums can produce spherical granules with a diameter of 1-6 mm from powdered raw materials. This granular form not only reduces dust, but also prevents separation of fertiliser components and ensures uniformity of application.

- Suitable for a wide range of fertiliser production: the granulation drum can be used to produce a wide range of inorganic fertilisers such as NPK compound fertilisers, Diammonium Phosphate (DAP), Monoammonium Phosphate (MAP), etc. It can also be used to produce a wide range of inorganic fertilisers through the addition of different liquid binders. It can also be used to produce granular fertilisers with slow-release properties by adding different liquid binders.

- Simple design and reliable operation: The basic structure of the granulation drum is simple, mainly consisting of a rotating cylinder and a liquid spraying device. This simple design allows for stable operation and low energy consumption, making it ideal for the needs of the fertiliser industry.

- Strong customisability: The granulation drum can be customised according to the characteristics of different fertilisers, such as adjusting the rotational speed, tilting angle, etc., in order to obtain the best granulation effect.

- Continuous technological progress: modern granulation drum adopts anti-corrosive lining, turning plate and other advanced designs, which further improve the performance of the equipment and product quality.

- High capacity: the granulation drum can achieve large-scale continuous production to meet the needs of industrial fertiliser production.

- Convenient for subsequent processing: the granulated fertiliser particles can be easily dried, cooled, screened and packed, simplifying the subsequent processing.

What are the main components of a rotary drum granulator?

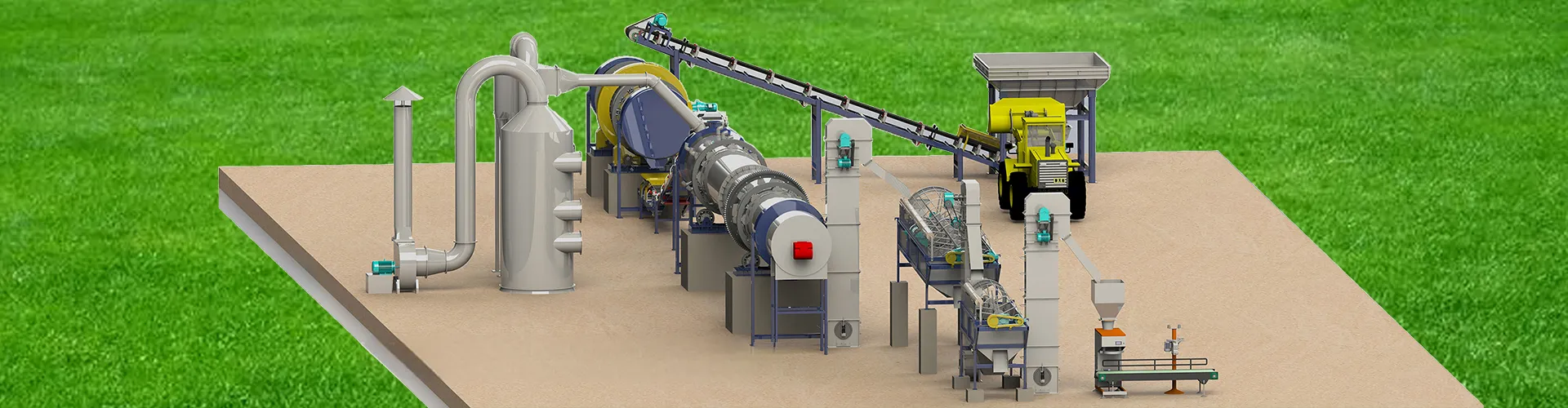

The main components of a rotary drum granulator include the core rotating drum, the power system (such as the motor and reducer) that drives the drum, the feed device that conveys the raw material, the liquid spray system that promotes the formation of the granules, the wheels and pulleys that support the drum, the discharge device that discharges the finished product, the control system that regulates the process parameters, and the shell and dust cover that reduces the amount of dust.

These components work in tandem and together achieve continuous conveying of the raw material, homogeneous mixing, granule moulding and discharge, thus completing the entire granulation process efficiently. Depending on the specific requirements, auxiliary equipment such as cleaning devices or temperature regulation systems may also be fitted to further optimise production results.

Design of granulation drums

The design of a rotary granulation drum is relatively simple – the raw material is fed into a large rotating cylinder, a liquid binder is added, and the material is tumbled inside the drum to form solid spherical pellets, sometimes utilising chemical reactions as part of the process. However, extensive design and engineering work is required to create high quality equipment capable of producing a consistent product at high volumes.

Before granulation drum design can begin, several questions must first be addressed, including:

- Is the material organic or inorganic?

- What is the nutrient content?

- Which binders are best suited for the required slow release while preventing degradation during storage and transport?

These and many other factors will influence the overall design of the granulation drum.

Having answered the materials question, the work will turn to the size aspect of the drum, which will control the required output (usually measured in tonnes per hour {tph}).

Finally, speed and drum inclination need to be considered. In order to achieve consistent granules, the granulation drum must run at a speed that allows the material to cascade down the side of the drum; too slow will cause the material to move back and forth across the bottom of the drum; too fast will cause the material to stick to the drum wall due to centrifugal force, and finding this balance is at the heart of granulation drum design and operation.

Advances in granulation drum design

Almost all industries have made great strides due to modern technology. Some of the key advances in granulation drum design include:

- Flexible and corrosion-resistant drum liners: liners can be used to reduce or eliminate the build-up of substances on the drum wall, as well as reduce potential damage caused by corrosive substances.

- Drum blades: Drum blades can be used to increase agitation of the material to refine the pouring effect and create the desired particle characteristics.

Conclusion

The granulation drum has become an important piece of equipment in modern fertiliser production thanks to its reliable performance and many advantages. It not only improves the quality of fertilisers, but also provides the possibility of diversification of fertiliser products. With the continuous progress of technology, the application prospect of granulation drum in fertiliser production will be more broad.

TONGLI has been a leader in granulation equipment for the fertiliser industry since 1958. Our granulation drums are known for their superior performance and reliability and are manufactured to the highest quality standards. Not only do we provide quality equipment, but we also have a state-of-the-art testing centre that offers comprehensive feasibility testing and process development services.

In addition, our after-sales team provides expert parts supply and technical support to ensure that your production line continues to run efficiently. Whether you need a customised pelletising solution or are looking to improve the efficiency of your existing production line, TONGLI is your reliable partner. Feel free to contact us to discuss how we can add value to your fertiliser production!