Operation instructions for each position of compound fertilizer production line

Compound fertilizer belt scale batching job guide

1. Compound fertilizer plant batching job tasks

According to production requirements and the proportion of various raw materials, it is responsible for delivering the mixed materials that meet the requirements to the crushing station, and at the same time recycling the plastic woven bags of various raw materials.

2. Process flow and process control indicators

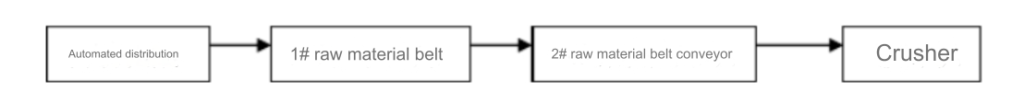

Introduction to the process

All kinds of raw fertilizers arriving at the factory are strictly measured according to the formula requirements and poured into the mixer. The mixture is evenly mixed, or the raw materials are poured into the silo. After being measured and evenly mixed, the mixture is sent to the crusher through the raw material belt conveyor.

Control indicators

(1) Feed size: ≤90mm (2) Feed rate: >10t/h (depending on the type)

3. Belt scale batching job management scope

Management area

The jurisdiction of this position includes all equipment, electrical appliances, buildings and structures from the automated batching system in the raw material warehouse to the raw material belt conveyor.

List of main equipment

| Serial number | Device Name | Detailed specifications and models | unit | quantity | Remark |

|---|---|---|---|---|---|

| 1 | 1# Raw material leather machine | B800×6×38000, reducer: ZQ400-3.15-1, i=31.5, center distance 400mm, motor: y160M-6-7.51KW | set | 1 set | |

| 2 | 2# Raw material leather machine | B800×6×38000 Reducer: ZQ350-31.5-1: Motor: Y132M₂-6-5.5KW | set | 1 set | |

| 3 | 1# Electronic belt scale | B800×6200, DEL0627 accuracy level 1.0, power 1.5KW, speed ratio i=381, maximum flow Q=4.8t/h, belt speed v=0.4m/s. | set | 1 set | |

| 4 | 2# Electronic belt scale | B800×6200, DEL0627 accuracy level 1.0, power 1.5KW, speed ratio i=461, maximum flow Q=3.2t/h, belt speed v=0.3m/s. | set | 1 set | |

| 5 | 3# Electronic belt scale | B800×6200, model: DEL0627, accuracy level 1.0, power 1.5KW, speed ratio i=619, maximum flow Q=4t/h, belt speed v=0.3m/s. | set | 1 set | |

| 6 | 4# Electronic belt scale | B800×6200, model: DEL0827, accuracy level 1.0, power 1.5KW, speed ratio i=461, maximum flow Q=3t/h, belt speed v=0.2m/s. | set | 1 set | |

| 7 | 5# Electronic belt scale | B800×6200, model: DEL0627, accuracy level 1.0, power 1.1KW, speed ratio i=945, maximum flow Q=1.5t/h, belt speed v=0.1m/s. | set | 1 set | |

| 8 | 6# Electronic belt scale | B800×6200, model: DEL0627, accuracy level 1.0, power 1.5KW, speed ratio i=619, maximum flow Q=4t/h, belt speed v=0.3m/s. | set | 1 set | |

| 9 | 7# Electronic belt scale | B800×6200, model: DEL0627, accuracy level 1.0, power 1.5KW, speed ratio i=619, maximum flow Q=4t/h, belt speed v=0.3m/s. | set | 1 set |

4. Compound fertilizer belt scale batching job procedures

Preparation before starting

1. After receiving the start-up command, first check whether the main parts of the electronic belt scale raw material belt conveyor, such as the motor, reducer, transmission belt, roller, and drum, are intact and whether there are any obstacles. Check whether the fastening bolts are loose and whether all lubricated parts are well lubricated. After checking, try to start the belt conveyor to check whether it has abnormal phenomena such as deviation and jamming until it runs normally.

2. Immediately empty the material in the hopper when taking over, then measure the skin, and then calibrate it with a standard bag, and record the measured new conversion coefficient in detail.

3. Prepare the post workers, tools and original records.

Start

1. After checking that the equipment is intact, contact the subsequent posts such as crushing to prepare for starting.

2. Start the raw material belt conveyor and electronic belt scale in turn. After the equipment is running normally, start feeding and normal operation.

Shutdown

After receiving the shutdown command, first stop feeding, and then drain the materials in the automatic batching hopper; first stop the mixer, electronic belt scale, and belt conveyor. After the shutdown, maintain the machinery and equipment, clean the automatic batching scale, and clean the environment. In case of an accident or equipment failure, emergency shutdown (including power outage), stop feeding and contact the subsequent process, and wait until the accident is handled before feeding and starting according to the procedure.

Key points for normal operation

Keep close contact with all positions, strictly follow the formula requirements, input the system according to the ratio, and add the various materials that have been measured to the hopper quantitatively and evenly. And keep the hopper with material, and never empty the hopper;

Abnormal phenomena and treatment methods

| Abnormal phenomenon | Cause | Solution |

|---|---|---|

|

1. No material on belt scale |

① Empty the hopper |

①Fill the hopper |

|

2. Belt deviation |

① The circumference of the two sides of the belt is not equal |

① Adjust the tensioning device |

Operation guide for crushing position in compound fertilizer production line

1. Compound fertilizer plant Broken job tasks

Responsible for the crushing of raw materials and return materials, and providing qualified materials for the granulation position.

2. Process flow and process control indicators

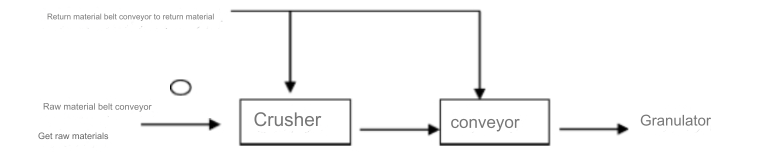

Brief introduction of process flow

The raw materials from the batching station and the returned materials from the screening station are crushed in the crusher, and the materials that meet the requirements are transported to the granulator through the bucket elevator.

Process control indicators

Feed: particle size ≤90mm

Discharge: ≤1mm, ≥90%

3. Management scope:

Management area

The management scope of this position: all equipment, electrical appliances, and structures from crushers to raw material bucket elevators, etc.

List of main equipment

| Serial number | Equipment name | Specifications and main parameters | Quantity |

|---|---|---|---|

| 1 | 2# conveyor |

The conveying capacity is 35m³/h, B800×56000 | 1 set |

| 2 | Chain Crusher |

Production capacity Q = 16-22t/h | 1 set |

4. Operating procedures

Preparation before starting

1. Carefully check whether the main parts of the chain crusher are intact, whether the fastening bolts are loose, and whether the lubrication is in good condition. Check whether the chain in the crusher is complete, whether there are three-section chains, if so, immediately fill or replace them. Check whether there is material sticking to the wall in the crushing chamber. If there is, it must be cleaned before driving.

2. Check whether there are foreign objects in the bucket elevator, and whether the reducer and bearings are well lubricated.

3. Prepare the post workers, tools and original records.

Start

1. After checking that the equipment is in good condition, contact the previous and next processes and prepare to start the machine.

2. Start the conveyor belt first, then start the crusher. After the equipment is running normally, start feeding and carry out normal operation.

Shutdown

After receiving the stop command, stop the crusher and conveyor belt after the system material processing is completed. After stopping, check and maintain the equipment under your jurisdiction. Check the chain wear, clean the accumulated materials in the bucket elevator and crusher, including the bucket elevator pit, and clean the environment. If an emergency stop is required due to an accident or equipment failure, contact the previous process to stop feeding and stop related equipment. After the accident is handled, start the machine according to the procedure.

Key points for normal operation

1. Check the motor current of each device regularly to see if it is normal

2. Check the crusher cavity, conveyor belt rollers, and crusher discharge port regularly to see if they are blocked or have accumulated materials. If problems are found, clean them up in time.

3. Check the crusher cavity for accumulated materials regularly and clean them up in time.

Abnormal phenomena and treatment methods

| Abnormal phenomenon | Cause analysis | Handling method |

|---|---|---|

|

1. The crusher makes abnormal sounds and the load increases. |

① Material accumulation in the cavity |

① Clean up, stop the machine for cleaning if the problem is serious |

|

2.Conveyor belt tripped |

①Too much material |

①Notify batching station to reduce feed amount |

|

3. The particle size of the material at the crusher outlet is too large |

① The feed is too large |

① Reduce the feed amount |

Granulation job guide in compound fertilizer production line

1. Compound fertilizer plant Granulation job tasks

Complete the granulation operation of the mixture, prepare compound fertilizer materials that meet the particle size requirements, optimize the operation process, improve the granulation rate of the mixed raw material, reduce the scarring of the granulator, and extend the cleaning cycle as much as possible.

2. Process flow and process control indicators

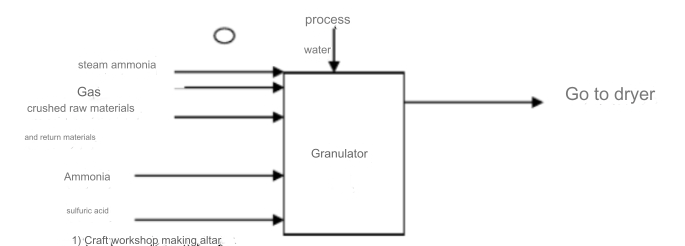

Brief introduction of process flow

The compound fertilizer mixed raw materials sent from the crushing station are agglomerated into granule cores under certain liquid phase conditions (sulfuric acid is first added to the machine, the amount of ammonia is adjusted, and the amount of steam is adjusted, etc.) by the extrusion force generated by the rotation of the cylinder in the granulator. The granule cores are constantly pressed with the rotation of the cylinder, and the surface is constantly agglomerated with powder particles. The volume of the granule cores is constantly increased to become compound fertilizer granules. The granules are polished in the polishing area of the granulator to make the surface smooth and then slide into the dryer for drying.

Process control indicators

1. Steam pressure ~0.6MPa 3. Ammonia pressure 0.4-0.6t/h

2. Granulation rate ≥65% 4. Sulfuric acid 0.2-0.3t/h

3. Management scope:

Management area

The management scope of this position: all equipment, process pipelines, valves, electrical appliances, buildings, structures, etc. in the granulator area.

List of main equipment

| Serial number | Equipment name | Specifications and main parameters | Quantity |

|---|---|---|---|

|

1 |

Granulator |

¢1800×6000n=12.3 rpm |

1 set |

4. Operating procedures

Preparation before starting

1. Check whether all parts of the granulator are intact, whether the lubrication is good, whether the inlet and outlet are unobstructed, and whether there are any debris in the machine;

2. Check whether the working state of the electrical system is normal;

3. Check whether the valves of each pipeline are intact and whether the valves are closed;

4. Start the granulator, rotate it for several circles, and stop and wait for orders if there is no abnormality;

5. Prepare the job tools, tools and original records.

Start

1. After receiving the start-up notice, notify the subsequent positions such as drying to start up, and prepare the boiler for steam supply;

2. Start the granulator;

3. Notify the raw material and crushing positions to start up and add materials to the granulator;

4. Introduce ammonia, sulfuric acid and steam into the granulator and adjust according to the process requirements.

Shutdown

1. After receiving the stop order, notify the raw material crushing station to stop and stop feeding into the machine;

2. Stop supplying ammonia, sulfuric acid and steam into the machine;

3. Stop the granulator after the material in the granulator is unloaded;

4. When the accident stops, stop feeding, water and steam immediately, and start according to the procedure after the accident is handled;

5. After stopping, the equipment should be maintained and cleaned, and the inlet and outlet should be cleaned and the internal scars should be handled.

Key points for normal operation

1. Granulation is a key position in compound fertilizer production. Operators should adjust the operating conditions at any time to increase the granulation rate of the material as much as possible.

2. Maintain the stability of the feed and discharge. When the feed volume fluctuates, the amount of steam, sulfuric acid, and steam should be adjusted in time to prevent the occurrence of excessive or small particles and adhesion.

3. Frequently check whether the motor current and bearing temperature rise of the equipment are normal.

4. Frequently check whether the inlet and outlet are unobstructed and whether the material is agglomerated inside. If found, deal with it in time.

Abnormal phenomena and treatment methods

| Abnormal phenomenon | Cause analysis | Handling method |

|---|---|---|

|

1. The granulator gear has periodic noise |

The large and small gears are not meshing well or the side clearance is too small |

Adjust the relative position of the large and small gears to ensure the gear contact area, tooth top and tooth side clearance |

|

2. Gears have impact sounds |

① The supporting wheel is seriously worn |

① Adjust the spacing of each set of supporting wheels in the front and rear supporting wheel devices. The outer circle is uneven and the finish is low. The outer circle of the wheel should be fine-turned |

|

3. Excessive vibration or axial movement of the cylinder |

① The bolts connecting the roller device and the bottom plate are loose |

① Tighten the connecting bolts |

|

4. The stopper wheel is severely worn |

The axial force of the cylinder is too large |

Adjust the support wheel to minimize the contact between the stopper wheel and the wheel belt |

|

5. Bearing temperature rise is too large |

① Lack of oil |

① Add oil |

|

6. The particle size of the material is too large |

① The amount of liquid phase is too large |

① Add steam and water at high speed |

|

7. The discharge particle size is too small |

① Insufficient liquid phase |

① Adjust the amount of steam and water |

Drying, cooling and screening job operation guide

1. Compound fertilizer plant Drying, cooling and screening job tasks

The granulated compound fertilizer delivered from the granulation station is dried, cooled and screened, the finished compound fertilizer that meets the requirements is transported to the packaging station, and the materials that do not meet the requirements are sent to the crushing station for re-crushing. At the same time, the exhaust gas of the dryer and cooler is dusted.

2. Process flow and process control indicators

Brief introduction of process flow

The material coming out of the granulator is sent to the dryer through the No. 3 belt for drying. The drying personnel should adjust the wind temperature and wind speed according to the formula requirements. The amine oxide series should adopt the principle of high temperature and high wind (temperature around 220℃). Low temperature and strong wind are most suitable for those with high urea content (110℃). The furnace fire should be kept stable, and the principle of frequent addition and small addition of coal should be adopted. After drying, the material is transported to the cooler through the No. 4 belt for cooling. The material is cooled to about 45℃. After cooling, the material is transported to the roller screen through the No. 5 belt. The front aperture of the screen is 1.00 and the rear aperture is 1.5-4mm. The material larger than 4mm is screened out at the rear outlet. After large-particle crushing, it is returned to the No. 1 belt together with the material screened out at the front end and enters the feeding system with the raw materials. The material of 1.5~4mm is transported to the secondary cooling through the No. 6 belt and then sent to the secondary screening through the No. 7 belt. The material that falls from the 2mm screen at the end of the screen enters the No. 1 belt, and the 2~4mm finished product material enters the coating machine for coating. The finished particles are added with anti-caking agent according to the standard under the rotation of the coating machine. The coating agent is evenly coated on the surface of the particles, and then the materials are transported to the finished product storage warehouse through the elevator through the rotation of the coating machine for packaging.

The qualified finished products are packaged by weighing, and the net weight of the packaging is 50 kg or 40 kg. The packaging bags are transported to the sewing machine for sealing by belt. The sealing should be strictly prevented from moisture. The folding edge is 2 cm high and there are 10 to 13 pinholes per meter. The packaging bags should be clean and clean. The finished products after packaging are transported to the warehouse for inspection and storage.

Process control indicators

1. Hot air temperature: 110-130℃ (urea system) 200-300℃ (ammoniation system) 300-450℃

(non-urea system)

2. Dryer exhaust temperature: 60-75℃ (urea system) 70-85℃ (non-urea system)

3. Dryer head negative pressure: ~20Pa (micro negative pressure)

4. Finished product particle size: 2-4.75mm≥90%

5. Finished product temperature: ≤40℃

3. Management scope:

1) Jurisdiction: Equipment, pipelines, valves, instruments, electrical appliances and surrounding buildings and structures under the jurisdiction of drying, crushing, screening and dust removal systems.

2) Main equipment

List of equipment for drying, cooling and screening positions

| Serial number | Equipment name | Specifications and main parameters | Quantity |

|---|---|---|---|

|

1 |

Rotary dryer |

φ2200×22000 η=2.71rpm,α=2.5° |

1 set |

|

2 |

Conveyor belt |

TH315, H=8000 |

1 set |

|

3 |

1# Roller Screen |

1200×3020 motor: ZG415 |

1 set |

|

4 |

1# Cooling Machine |

φ1500×13400 η=3.28 rpm, V=23.68m³ |

1 set |

|

5 |

conveyor |

The conveying capacity is 35m³/h |

1 set |

|

6 |

2# Roller Screen |

60×600 motor: YZQ-20-6 |

1 set |

|

7 |

2# Cooling Machine |

LH1513φ1500×13000 |

1 set |

|

8 |

1# Return tape |

B650×9200, |

1 set |

|

9 |

2# Return tape |

B650×46700, |

1 set |

|

10 |

3# Return tape |

B650×16100 |

1 set |

|

11 |

Drying induced draft fan |

4-72 model NO10D Q=43690m³/h P total pressure=214mmHg |

1 set |

|

12 |

1# Cooling fan |

4-72-8C Q=27450-34800m³/h P total pressure=2933-2363Pₐ |

1 set |

|

13 |

2# Cooling fan |

4-72-10 Q=33554m³/h P total pressure=1257Pₐ |

1 set |

4. Operating procedures

Preparation before starting

1. Check whether all running equipment is flexible and whether there is any jamming.

2. Check whether all main parts of the equipment are intact, whether the fastening bolts are loose, and whether the lubrication is good

3. Check whether the electrical system is in normal condition.

4. Check whether each discharge port is unobstructed and whether there are foreign objects in the equipment.

5. Check whether the dust removal system pipeline is unobstructed, whether there is material accumulation, and whether there is any air leakage.

6. Check whether the rolling screen is intact.

After the above inspection, the situation should be handled in time, and wait for orders after everything is normal.

Start

1. After receiving the start-up order, start the exhaust fan and cooling fan in sequence.

2. Start the equipment in sequence: return belt conveyor, roller screen, cooler, dryer.

3. After all equipment is operating normally, notify the hot air furnace station to send hot air and the granulation station to feed materials for normal operation.

Shutdown

1. After receiving the stop command, notify the hot air furnace to stop sending hot air and the granulation station to stop feeding. After the material in the system is drained, stop the equipment in sequence: dryer, cooler, roller screen, return belt conveyor, fan. (Note: The dryer should be stopped only when the cylinder temperature drops below 60℃)

2. In case of accidental stop, the hot air furnace and granulation stations should be notified in time to stop sending hot air and materials. After the accident is handled, start the car according to the procedure. (If the accident takes a long time to handle, the dryer should be rotated for 30 to 45 minutes for one week until the cylinder cools down)

3. After stopping, the maintenance and environmental sanitation of each equipment should be done well, and at the same time, the equipment and pipelines should be thoroughly checked for material accumulation.

Key points for normal operation

1. Strengthen patrol inspections and regularly check whether the motors, currents, and bearing temperature rises of each device are normal. If abnormalities are found, find out the causes and deal with them quickly.

2. Check whether the inlet and outlet ports of each device and the dust removal system pipelines are unobstructed at any time.

3. Observe the changes in the particle size of the dry material at any time. If there are any abnormalities, notify the granulation post to adjust the operating conditions in time.

4. Regularly check whether the rolling screen is blocked, accumulated, or damaged.

5. Keep the system inlet and outlet continuous and stable. If there are any abnormalities, adjust the operating conditions in time to keep the process indicators within the control range.

6. Check the appearance quality of the finished material at any time. If abnormalities are found, the causes should be quickly found out and dealt with in time.

Abnormal phenomena and treatment methods

| Abnormal phenomenon | Cause analysis | Handling method |

|---|---|---|

|

1. The moisture content of the material after drying is greater than the specified value |

① Insufficient heat supply |

① Increase the heat supply |

|

2. The moisture content of the material after drying is lower than the specified value |

The opposite of the situation described in 1 |

The opposite of the treatment method described in 1 |

|

3. The material melts and sinters in the dryer |

① The temperature of the inlet flue is too high or the gas volume is too large |

① Reduce the temperature and wind speed |

|

4. High temperature of dryer exhaust gas |

①High inlet temperature |

①Lower temperature |

|

5. The temperature at the end of the dryer is too low |

The opposite of the situation described in 4 |

The opposite of the treatment method described in 4 |

|

6. The negative pressure of the drying head is too large |

① The opening of the tail gas fan butterfly valve is too large |

① Reduce the opening of the butterfly valve |

|

7. The dryer is under positive pressure |

①The opposite of 6 |

①The opposite of 6 |

|

8. High temperature of finished product |

① Too much feed |

① Reduce feed |

|

9. The finished product contains a lot of fine powder |

① The screen of roller screen I is blocked | |

|

10. Large particles appear in the finished product |

① Partial damage to the screen of roller screen II |

① Stop the machine to repair or replace the screen |

|

11. Exhaust fan vibration intensifies |

① Blade scaling |

① Stop and clean |

|

12. Exhaust dust with exhaust |

① Too much material accumulated in box-type dust collector | ① Cleaning ②) Cleaning |

Note: For abnormal phenomena and treatment methods of dryers, coolers, belt conveyors and other equipment during operation, please refer to granulators and raw material belt conveyors

Hot blast furnace job guide

1. Compound fertilizer plant Hot air furnace job tasks

Responsible for the operation of the hot air furnace, providing flue gas that meets the process requirements to the drying station, the main process of low temperature and large air volume strives to improve the combustion rate of coal and reduce coal consumption, and at the same time, do a good job in the management of coal yards and slag yards.

2. Process flow and process control indicators

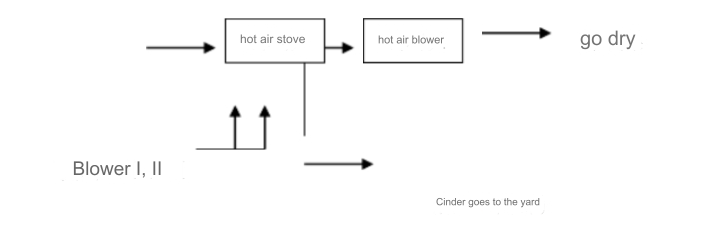

Brief introduction of process flow

Coal is manually fed into the fixed grate of the hot blast furnace, air is blown into the furnace, and the air intake of the blower is adjusted to ensure the combustion rate of the coal. The high-temperature smoke formed by the combustion is ventilated through the hot air blower to the drying station. The coal slag after the coal combustion is manually taken out from the fixed grate and sent to the yard.

Process control indicators

Hot air furnace outlet temperature: 200~300℃

Dryer inlet temperature 110~130℃ (urea system) 250~400℃ (non-urea system)

3. Management scope:

1) Management area: equipment, pipelines, valves, instruments, electrical appliances, structures and buildings belonging to the hot air furnace system.

2) List of main equipment

| Serial number | Equipment name | Specifications and main parameters | Quantity |

|---|---|---|---|

|

1 |

Hot air furnace |

4130×2150×3365 |

1 set |

|

2 | Hot air blower |

W5-48 type-10D size Q=21500-33500m³/h |

1 set |

4. Operating procedures

- Preparation before starting:

1. Check whether the grate is complete, whether there are foreign objects on the grate, and whether the furnace is intact.

2. Check whether all rotating equipment is normal, whether the lubrication of each equipment is good, and whether the butterfly valve of the hot air blower is in a closed state.

3. Check whether the coal feeder is blocked or blocked.

4. Prepare the ignition materials, dry firewood, etc. for ignition, and spread a layer of ignition materials on the grate.

5. Check the coal reserves and prepare enough fuel. - Start:

1. After receiving the ignition command, ignite the ignition materials on the grate, wait for the firewood to burn, and then spread a layer of coal to burn. Start the coal feeder and feed coal into the furnace and grate. Adjust the amount of coal fed according to the situation.

2. Start the blowers I and II to adjust the opening of the inlet valve (limited to maintaining a slight negative pressure in the hot air furnace).

3. After the furnace temperature reaches the requirement, notify the subsequent positions to start.

4. After receiving the air supply command (the dry exhaust fan has been started), turn on the hot air blower. Open the flue gas butterfly valve and adjust the opening of the blower butterfly valve at the same time (limited to maintaining the negative pressure operation of the hot air furnace). Adjust the combustion situation, control the furnace temperature, flue gas temperature and dryer inlet temperature.

5. Adjust the hot air blower inlet butterfly valve and the air distribution butterfly valve. - Stop:

1. After receiving the stop command, stop the hot air blower, close the inlet butterfly valve, stop the blower, stop the coal feeder, and cover the burning coal with a layer of coal to suppress the fire.

2. If the plan is to stop (the hot air furnace is turned off), stop feeding coal into the coal hopper, and after the coal is basically burned, remove the coal slag on the grate.

3. During the stop period, the equipment should be maintained and cleaned. - Key points for normal operation:

1. Add coal to the coal hopper at any time to ensure continuous coal, and remove the coal slag on the grate at any time to ensure good combustion.

2. Adjust the opening of the blower inlet butterfly valve and the hot air blower inlet butterfly valve.

3. Frequently observe the furnace combustion conditions and control the furnace temperature, negative pressure, flue gas temperature out of the furnace and hot air temperature into the dryer. - Abnormal phenomena and treatment methods:

| Abnormal phenomenon | Cause analysis | Handling method |

|---|---|---|

|

1. The temperature of the smoke coming out of the furnace is low |

① Low furnace temperature |

①Increase furnace temperature |

|

2. The furnace is under positive pressure |

① The exhaust volume is too small |

① Increase the shaft air volume |

Packaging job operation guide

1. Job Responsibilities

The compound fertilizer produced by this class is packaged and stored according to quality and quantity, and measured. At the same time, samples of finished products are taken regularly and quantitatively and aggregated.

2. Process flow and process control indicators

1) Process description:

Discharge the material from the bottom discharge port of the finished product storage hopper and weigh it, then fold the edge of the finished product belt conveyor, and then sew it through the sewing machine, and use a forklift to deliver it to the finished product warehouse for storage and palletizing.

2) Process control indicators:

1. Packaging quality 50±0.5kg/bag

2. Number of stitches at the seam 10~13 stitches/10cm

3. Management scope:

1) Management area: Equipment, electrical appliances, tools, buildings, structures, etc. belonging to the finished product packaging position.

2) List of main equipment:

| Serial number | Equipment name | Specifications and main parameters | Quantity |

|---|---|---|---|

|

1 |

Finished product storage hopper |

φ2000×2840 |

1 set |

|

2 |

Packing belt conveyor |

B320×9640 |

1 set |

|

3 |

Bag sewing machine |

GK35-2C |

1 set |

|

4 |

Electronic platform scale |

TCS-150 type |

1 set |

4. Operating procedures

- Preparation and inspection before driving:

1. Check whether the electrical appliances and equipment are normal.

2. Check whether the belt conveyor and bag sewing machine are well lubricated.

3. Prepare packaging bags, bag sewing threads, etc.

4. Prepare the tools, certificates, original records, etc. of this position.

5. Test run the belt conveyor and bag sewing machine, and deal with the situation in time. - Driving:

1. After receiving the driving order, start the finished product belt conveyor.

2. After the material in the finished product storage hopper has a certain storage volume, start to put the bag → weigh → fold the edge → sew the mouth.

3. Push the packaged finished products to the finished product warehouse with a trolley and stack them neatly.

4. Before handing over the shift, all the finished products produced in this shift should be packaged and the original records should be made. - Stopping:

1. After receiving the stop order, stop the belt conveyor and bag sewing machine after the finished products are packaged.

2. If the equipment in this position fails, it should be repaired or replaced with spare equipment in time.

3. During the parking period, the maintenance and sanitation of the equipment in this position should be done well. - Key points for normal operation:

1. Check whether the finished product belt conveyor is off track and whether the bag sewing machine (including the spare machine) is in good condition. Check whether the feeding port is blocked. Ensure that the equipment is in good condition to prevent the whole system from stopping due to equipment failure in this position.

2. Check whether the packaging quality and sealing meet the requirements when finished, and check the scale to ensure that the weighing error is within the error range.

3. Take a sample of the finished product once every hour and gather the samples.

4. Strengthen the sense of responsibility for work, operate carefully, and ensure that the packaging quality pass rate is 100%.

5. Ensure that each package has complete labels.

6. The bundling and sewing of the packaging should be correct and firm, without leakage, moisture absorption, and clean appearance. - Abnormal phenomena and treatment methods:

| Abnormal phenomenon | Cause analysis | Handling method |

|---|---|---|

|

1. Belt deviation |

Same batching position |

Same batching position |

|

2. Thread breakage in sewing |

①Wrong threading |

①Rethread as required |