Drum fertilizer mixer/mixing machine/blender

The purpose of the cylindrical fertilizer mixer is:

- to mix multiple materials into a uniform mixture. For example, cement, sand, gravel, and water are mixed into concrete wet material.

- Increase the contact surface area of materials to promote chemical reactions. For example, in the gas-liquid phase catalytic reaction, it is necessary to make the solid powder catalyst or liquid catalyst (density is different from the liquid participating in the reaction) evenly suspended in the liquid, and the gas is formed into small bubbles and evenly dispersed in the liquid.

- Accelerate physical changes. For example, the addition of granular solutes to solvents can accelerate the dissolution and mixing through the action of mixing machinery. It is divided into three types: large, medium, and small.

Introduction: what is a cow dung organic fertilizer blender?

- The fertilizer blender is one of the important equipment in the sintering and pelletizing system. It can be used for raw material mixing, granulation, rolling coal, and other purposes to meet the requirements of sintering machines for raw materials.

- The transmission structure of this series of cylindrical mixers mainly includes gear transmission and rubber wheel transmission. Gear ring transmission has the characteristics of large transmission torque and long life, but the noise is relatively large; rubber wheel transmission can use solid or hollow pneumatic tires, which has the characteristics of stable transmission and low noise, but the rubber wheel wears more and needs to be replaced more frequently.

- The transmission device of the rubber wheel drive can be placed in the middle or at both ends according to user requirements. All equipment has left and right transmission installation forms. To improve the mixing effect, a lifting plate is installed in the cylinder;

- To prevent sticking, the cylinder is also equipped with a whole or part of the lining. The lining is made of metal, wear-resistant rubber, oil-containing nylon, polymer materials, etc.

1. Mixing machine for organics overview

Nowadays, cylindrical mixers are mostly used in sintering production. As the scale of sintering machines increases day by day, Fertilizer blenders also increase in size. The specifications of mixers are calculated and selected based on the processing volume and mixing time. The increase in the scale of large cylindrical mixers has led to an increase in the difficulty of installation. This article gives a general description of the structure and installation characteristics of the mixer.

2. Structural features of drum mixer/blender

The structure of the newly designed large-scale drum mixer has many advantages. And the transmission accuracy is also high.

- It is equipped with micro-transmission, connected by a claw clutch, which can make the drum body rotate forward and reverse slowly during installation and maintenance. It is convenient for operation, adjustment, and cleaning.

- The cylinder is welded as a whole. The roller is forged as a whole. The roller and the steel plate weld the cylinder. The roller is forged as a whole and it is part of the cylinder. This structure is easy to manufacture. The cylinder is simple to install, and the cylinder rigidity is large, which avoids the sliding phenomenon between the roller and the cylinder during operation. The roller has a long service life. Its cross-section adopts a solid trapezoidal shape with a simple shape. It is easy to manufacture. The large gear ring is cast steel, manufactured in two halves, connected by bolts, and connected to the fixed frame on the cylinder by hinged matching bolts and ordinary bolts. Adjust according to the special reference set on the cylinder during installation.

- To prevent wear in the cylinder improve the mixing effect and prevent sticking. There is no metal lifting plate in the cylinder. All are equipped with wear-resistant rubber lining plates and lifting plates. Within the 1.5m section of the feeding end, the wear-resistant rubber lifting plate is at a certain angle to the center line of the mixer, and the spiral lifting plate plays the role of guiding the material to the discharge end.

- The general spiral angle is 15. ~20. The remaining wear-resistant rubber lining plates and rubber pressure strips are parallel to the center line of the cylinder. The contact surface between the rubber lining plate and the inner surface of the cylinder is designed to be grooved. During the operation of the cylinder, the surface of the lining plate in contact with the material is always active. The material impacts the lining plate to make it concave.

- When the material runs from the low point to the highest point, due to the gravity of the material, the lining plate changes from concave to convex, so that the material that is temporarily stuck to the lining plate is also shaken off so that the cylinder does not stick to the material. The rubber pressure strip can also play the role of lifting the plate. The fixing bolts are not exposed, and are all in the lining plate, not in contact with the material, to avoid the lining plate falling off after wear and damage. Since the full rubber lining does not stick to the material, the mixing effect is improved.

- Adopt an integral roller base and a dispersed transmission part base. The base of a pair of rollers is an integral whole, which is convenient for installation and adjustment, and can ensure the installation accuracy. The base of the transmission part is separate, with a simple structure, easy manufacturing, lightweight, and convenient installation and adjustment.

- The reducer housing and gears adopt a welded structure. Considering the convenience of installation, the reducer cover of the secondary mixer is divided into two halves. This structure has a beautiful appearance and lightweight, and the welded gears can make reasonable use of materials. The structure is reasonable and the appearance is regular, but the welding technology is high and it is not easy to ensure the quality.

- Automatic oil spray lubrication. The contact surface lubrication between the roller and the roller, between the roller and the thrust roller, and between the pinion and the large gear is automatic oil spray lubrication. Use an effective lubrication method and lubrication system. Because the thick oil film has a strong load-bearing capacity, the friction surface is completely separated by the oil film, and the friction between the friction parts is replaced by the internal friction of the lubricating oil. This fluid dynamic lubrication is the most ideal lubrication state. Automatic oil spray lubrication is adopted to ensure that the friction surface is evenly oiled. The wear of the friction parts is avoided, and the service life of the friction parts is greatly extended.

3. Installation of cylindrical blending machine for NPK

Construction sequence:

Construction preparation—foundation acceptance—measurement and layout—pad slurry—installation and adjustment of roller base and roller—positioning of retaining roller—positioning of cylinder—adjustment of cylinder and retaining roller—installation of large gear ring—installation of transmission device—trial operation

How to installation a fertilizer cylindrical mixer:

Fertilizer mizer roller installation guide

The difficulty of installing a large Tongli mixer is that its cylinder is in a straight line with a certain angle, and the installation angle must be guaranteed. To ensure the quality of installation, we can use the following methods.

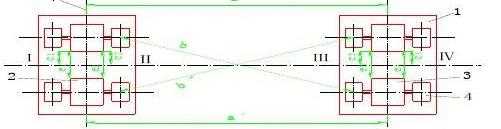

- Rough alignment of roller base and roller: lift the roller and base onto the placed pad iron, put on the anchor bolts, and prepare for alignment. Find the center points Ⅰ, Ⅱ, Ⅲ, and Ⅳ on the upper and lower roller bases respectively so that they fall on the longitudinal and transverse center lines determined in advance; measure the center distance of the upper and lower rollers, and adjust them to match the size of the drawing; use a measuring instrument to check the elevation above the upper and lower rollers and adjust the height of the pad to ensure that the measured value is consistent with the required size of the drawing. At this time, grouting can be carried out once, and after the anchor bolts meet the strength requirements, the next step of fine alignment can be carried out.

- Fine alignment of roller base and roller: To control the installation accuracy of the roller, the key is to ensure the inclination of the cylinder and the contact area between the roller and the roller ring while the cylinder is in place. The specific construction process is as follows:

- Measure the distances c1, c2, c3, and c4 between the ends of the upper and lower rollers and the longitudinal center line of the mixer, so that the distance difference c1-c2, c3-c4 ≤ 1mm;

- Measure the diagonal lengths b and bˊ of the bearing seats of the upper and lower rollers, so that b-bˊ ≤ 1mm;

- Adjust the adjustment bolts of the bearing seat to make e1-e2, e3-e4 ≤ 1mm;

- Control the inclination of the upper and lower rollers.

- To control the inclination of the cylinder and the contact area between the roller and the roller ring, we should not only control the elevation of the two points f and fˊ of the roller center, but also calculate the elevation of each point f1, f2, f3, f4 according to the roller length and the cylinder inclination, and adjust the height of the pad to ensure that the elevations of these four points meet the requirements.

- After alignment, use the angled shim module made in advance to fit its beveled edge with the longitudinal direction of the upper surface of the roller, and use a level to check the horizontality of the long right-angled side of the module (i.e. the upper surface). By using the above two methods to align together, it can be ensured that the elevation and angle of the upper and lower rollers meet the requirements of the drawings and specifications. After the roller base and roller are fine-tuned, tighten the anchor bolts and connecting bolts, and perform secondary grouting after the mixer barrel is fine-tuned.

- Rollers and base: 1—base; 2—upper roller; 3—lower roller; 4—bearing seat; 5—longitudinal center line of the base; 6—lateral center line of the base; 7—axial center line of the roller; f, fˊ—center points of the upper surface of the roller; f1, f2, f3, f4—end points of the upper surface of the roller.

Fertilizer rotary blender cylinder Installation

- After the cylinder is in place, use the guide chain to pull the cylinder to rotate. During the rotation process, the cylinder will move downward due to its own weight. When the roller and the center line of the roller width coincide, adjust the roller surface of the lower retaining roller to contact the retaining ring, and then completely tighten the tension bolts between the upper and lower retaining rollers, so as to complete the axial positioning of the entire cylinder.

- The retaining wheel device bears the axial force generated by the inclined installation of the cylinder and the additional axial force generated after the gear meshing, limiting the axial movement of the cylinder. The retaining wheels are installed in pairs on both sides of the roller on the side of the discharge port, and contact the side of the roller through the tapered wheel surface. Adjust the contact area between the roller and the roller.

- After the cylinder is positioned, continue to pull the cylinder with the guide chain, and at the same time check the contact surface between the roller and the roller (check the gap between the roller and the roller with a 0.05mm feeler gauge), and make fine adjustments through the adjustment bolts of the roller base and the roller bearing seat.

- After adjustment, continue to rotate the cylinder and repeat the above adjustment process until the contact surface meets the design and specification requirements. The roller ring is required to have good contact with the roller surface, and the contact width must not be less than 60% of the full width of the roller ring. Use a 0.05mm feeler gauge to check all of them.

Installation of the fertilizer blender girth gear/big gear

- The large gear ring is split from top to bottom and cast, and a support plate for the gear ring is installed on the cylinder. Before installing the large gear ring, check the manufacturing accuracy of the support plate. Its runout should be less than 1mm and the radial runout should be less than 1.5mm. If the manufacturing is out of tolerance, the manufacturer must be notified to handle it.

- The crane lifts a half gear ring from the bottom of the cylinder, rotates the cylinder with a chain, and restores the corresponding holes during the hinge according to the marks made during the manufacturing process, so that the bolt holes on the half gear ring are aligned with the bolt holes on the gear ring frame, and the fastening bolts are connected. Rotate the cylinder 180°, lift the other half gear ring from the bottom of the cylinder with a crane, connect the two half gear rings together with bolts, and connect them with the gear ring frame with bolts.

- Rotate the cylinder again to check the radial runout and end face runout of the gear ring. The end face runout is guaranteed by the manufacturer’s manufacturing tolerance. The key is to ensure the radial runout tolerance of the gear ring. Fix a dial indicator on the outside of the gear ring and measure the data every time the cylinder rotates 1/8 of a revolution. After analyzing the measured data, use a jack to make appropriate adjustments to the position of the gear ring. Rotate the cylinder again and repeat the above measurements and adjustments until the radial runout tolerance meets the requirements.

horizontal blender transmission device

- The main transmission device of the horizontal fertilizer blender is composed of the main motor, hydraulic coupling, coupling, main reducer, and gear ring pair to achieve normal operation of the equipment. In addition, the cycloid reducer, claw clutch, main reducer, and gear ring pair are used to realize the micro-motion operation of the mixer.

- Apply red lead powder on the pinion gear, and adjust the meshing of the two gears by moving the horizontal position and height of the pinion bearing seat. After installation and fixation, the mutual meshing of the large and small gears should be ensured to be good, the tooth surface contact along the tooth height direction should be greater than 40%, the tooth length direction should be greater than 50%, and the tooth side clearance should be between 1.1 and 1.8 mm.

- Use the pinion gear coupling after alignment as the reference to align the hydraulic coupling; use the hydraulic coupling coupling after alignment as the reference to align the reducer; use the reducer input shaft coupling as the reference to align the main motor and micro-motion motor.

4. Key points for installation of large drum fertilizer agitator

- When installing rollers, the installation accuracy must be strictly controlled to ensure that the corresponding upper and lower roller upper surface connection line is on a straight line at a certain angle (drum inclination) to the ground.

- When installing the drum, ensure the contact area between the support ring and the roller surface.

- When installing the large gear ring, strictly control the radial runout of the large gear ring.

- When installing the pinion, the large gear ring must be used as a reference to ensure the installation accuracy of the pinion. Because the installation of the transmission part in the next step is based on the pinion, the installation accuracy of the pinion is crucial.

- When installing the fixed end (no gap between the bearing side and the seat) and the free end of the roller bearing seat, pay attention to the relationship with the inclination direction of the drum. The bearing seat at the fixed end must be on the discharge end side of the drum, and the bearing seat at the free end must be on the feeding end side to prevent the downward force generated by the drum on the roller and the pinion from acting on the shaft, causing the tapered sleeve to tighten the inner sleeve of the bearing and damage the bearing.

5. Working Principle of Drum Mixer

- The working process of fertilizer mixing equipment is that the belt conveyor directly or through the feeding funnel continuously inputs the mixed material into the cylinder.

- As the cylinder rotates, the mixed material in the cylinder is continuously brought to a certain height and then thrown down and tumbled, and moves forward along the cylinder, forming a spiral motion.

- From the beginning to the end, after multiple cycles, the mixing, granulation, and appropriate amount of water are completed, and then it reaches the tail and is discharged through the chute.

6. Working process of Fertilizer drum mixer

- The Fertilizer drum mixer(Fertilizer mixing machine) is installed with an inclination angle of 1.5°-4° so that the center of the drum inlet and the discharge port have a height difference.

- The materials are mixed and moved forward by the force component of the material gravity. The entire drum is located on the front and rear sets of roller devices through two rollers and can rotate freely.

- A group of blocking wheels are installed on the base seat of the front roller group (located at the discharge end). The blocking wheels and the side of the rollers are in contact, bearing the downward force of the cylinder and restricting the axial movement of the cylinder.

- The transmission device is installed on the side base of the cylinder, and the cylinder is rotated through the transmission pinion and the large gear ring on the cylinder device. The transmission device of the Baosteel drum mixer also has a micro-motion auxiliary transmission, which is used for micro-rotation when installing and maintaining the drive cylinder.

- The sprinkler pipe of the primary mixer runs through the entire cylinder. A nozzle is installed on the sprinkler pipe at a certain interval to spray water evenly along the length direction. The secondary mixer only extends three water pipes of different lengths at the feeding end, each with a nozzle for fine-tuning the water content.

7. General working conditions of fertilizer rotary mixer

- Medium and small sintering plants usually configure the primary mixer on the ground and the secondary mixer on the top floor of the main sintering plant. This avoids the breakage of the pellets caused by long-distance transportation of the mixed materials after mixing and granulation, as well as humidity and temperature fluctuations, which affect the output and quality of sintering.

- Since the mixed materials in the rotating cylinder are in a skewed state, it is like adding an eccentric mass exciter to the cylinder, and there must be vibration. If it is directly transmitted to the high-rise floor, it will cause vibration of the floor and even the entire plant, affecting the normal production of the sintering machine.

- For this reason, a variety of fertilizer drum mixers with vibration absorption performance have been developed. A drum mixer equipped with a vibration absorber has vibration absorbers installed between the roller ring and the cylinder and between the support seat and the floor.

- The coupling in the transmission device adopts an elastic compensation coupling. Because the vibration absorber is a composite of rubber and metal, it has a good characteristic of absorbing high-frequency vibration energy, which greatly reduces the vibration caused by eccentric falling.

- Another type is a drum mixer driven by rubber wheels. The drum rotates on four sets of rubber wheels, two of which are driving wheels on one side. The vibration of the mixer and the floor is eliminated by using the cushioning and vibration absorption performance of the rubber wheels. For fertilizer drum mixers in large sintering plants, the rotating mass and contact pressure are very large, so the above-mentioned mixer is not suitable. It is best to set the primary and secondary mixers on the floor.

8. Development of Fertilizer Cylinder Mixer

- The development of fertilizer mixer equipment in my country is synchronized with the development of the sintering and fertilizer industry and has experienced a development process from simple to gradually improved, from small to large. In the late 1970s, my country had independently designed and manufactured a variety of different specifications of cylinder fertilizer mixers, with a maximum diameter of 3m and a length of 12m, and formed a series of products to meet the needs of sintering machine development. In the 1980s, especially after the 450m2 sintering machine introduced by Baosteel was completed and put into production, it strongly promoted the development of my country’s sintering industry, and the design and manufacturing level of cylinder mixers also newly improved. The design and manufacturing technology of large cylinder mixers supporting 264m2, 300m2, and 435m2 sintering machines was solved independently.

9. Difficulties in manufacturing large-scale fertilizer mixing machine

Although we have accumulated many years of experience in manufacturing fertilizer mixing machine, the mixers we manufacture are large in size and have high technical requirements than large mixers. The connection between the roller and the drum is mostly bolted or the roller is inserted into the drum and adjusted with gaskets before welding; the roller is a cast steel part; the drum of a small mixer is easy to heat treat as a whole; the drum accuracy can be guaranteed by processing. However, the manufacturing and processing of the drum mixer equipped with the 435m2 sintering machine of steel has the following difficulties:

- Large size: The weight of a single piece of the secondary fertilizer mixer drum is 210t, the inner diameter is 5.1m, the length is 29m, the net weight of the roller is 42.5t, and the size is φ5.74/φ5.1×29m.

- High precision: The design requires that the radial runout of the cylinder roller and flange should not exceed φ2.0mm by light inspection; the radial runout of the cylinder flange should not exceed 2.0mm; the end face runout is 0.3mm; the perpendicularity of the joint surface of the gear ring frame and the gear ring to the common axis of the cylinder is 0.5mm.

- Difficult forging and welding: It is also very difficult to directly forge the integrally forged roller on a general 10,000-ton hydraulic press. At present, the domestic manufacturers with 10,000-ton hydraulic presses are the Shanghai Heavy Machinery Plant, the Second Heavy Machinery Plant, and the First Heavy Machinery Plant. The production of the 10,000-ton hydraulic presses of the TONGLi Heavy Machinery Plant and the Second Heavy Machinery Plant requires the use of the external forging method, and requires considerable modification costs; certain measures must also be taken in the production of the TONGLI Heavy Machinery Plant. The roller is directly welded to the cylinder, the cylinder weld needs to be annealed, and the coaxial form and position tolerance of the cylinder should be guaranteed. The processing cycle of the large gear ring is long and the process is complicated. In addition, the land transportation of the cylinder and roller is also very difficult.