TONGLi LCMC type compound fertilizer/cement low-pressure long bag pulse dust collector

- TONGLi LCMC type compound fertilizer/cement low-pressure long bag pulse dust collector is based on the design and manufacturing experience of LCM type low-pressure long bag pulse dust collector, especially for the ultra-low emission requirements of the fertilizer and machinery industries. A new generation of low-pressure long bag pulse dust collector is developed and designed. . The product retains the advantages of the long bag pulse dust collector and gives full play to the advantages of pulse injection dust cleaning. The product adopts temperature-resistant, anti-corrosion, high-filtration precision filter material, which is used in the compound fertilizer industry and ultra-clean filtration of flue gas in the cement industry to meet ultra-low emissions.

Pulse bag filter dust collector description

- Tongli LPMC gas shock pulse bag dust collector is a new type of air box pulse high-efficiency bag dust collector developed and manufactured by Tongli on the basis of inheriting the advantages of LPM series bag filter. This product has a compact structure and occupies a small area.

- It adopts large-size pulse valve chamber overall dust cleaning technology. It has the characteristics of strong dust cleaning ability, good effect and long service life. It is especially suitable for the control of high concentration dust. It is widely used in ultra-clean filtration of dusty waste gas in industries such as fertilizer industry, building materials, cement, metallurgy, machinery, chemicals and refractory materials to meet ultra-low emission requirements.

- TONGLI LPMC type gas shock bag dust collector has four series and 35 specifications. The filter area is 120~4462m2, and the air volume range is 5020~240954m2/h.

Pulse bag filter dust collector data table parameter specification

| Model | Air volume | Filter Area | # of chamber | # of filter bag | Gas consumption | Weight |

|---|---|---|---|---|---|---|

| LPMC-6A | 10000~13000m3/h | 239m2 | 6 | 192 | 0.55m3/min | 6735kg |

| LPMC-5B | 16789~22500m3/h | 398m2 | 5 | 320 | 1.5m3/min | 10495kg |

| LPMC-8B | 26733~34500m3/h | 637m2 | 8 | 512 | 2.4m3/min | 15620kg |

| LPMC-7C | 35184~45200m3/h | 837m2 | 7 | 720 | 2.1m3/min | 18500kg |

| LPMC-2x7C | 70728~90345m3/h | 1673m2 | 14 | 1555 | 4.2m3/min | 37500kg |

| LPMC-7D | 46850~60000m3/h | 1116m2 | 7 | 896 | 4.2m3/min | 25410kg |

- So here we have listed some of the specifications, but making a table in wordpress is way too complicated therefore, for more detail please send a message.

Instructions Pulse jet bag filter dust collector specification table:

- Filter wind speed selection: 0.7~0.9m/min;

- Dust collector resistance: 1200~1500Pa;

- The allowable dust concentration at the entrance of the dust collector is: LPMC-A series: <200g/m2, LPMC-B series: <1000g/m2, LPMC-C/D series: <1300g/m2.

- Dust concentration at the outlet of the dust collector: <10mg/m2;

- Cleaning compressed air pressure: 0.5~0.7MPa;

- Pulse valve specifications, LPMC-A series: 1.5-inch right-angle valve, LPMC-B/C/D series: 2.5-inch right-angle valve;

- Filter bag specifications: LPMC-A/B/C/D type: medium 130x3050mm; the filter bag can be lengthened according to user needs, up to 3500mm.

- The dust collector shell can withstand negative pressure: 5000Pa;

- The net filtration area in the table refers to the filtration area when one room is being cleaned. The total weight of the equipment does not include the weight of the insulation layer.

- The air consumption in the table refers to the centralized air supply in the factory. For example, when a separate air compressor is installed, the air consumption in the table must be multiplied by a factor of 1.3.

- Equipped with ash conveying device: LPMC-B type is equipped with ∮300 screw conveyor, conveying capacity 30m3/h, reducer model XWD2.2-5-1/43, power 2.2KW; LPMC-C type is in use 400 screw conveyor, conveying capacity 38m2/h, reducer model XWD5.5-7-1/59, power 5.5KW;

LPMC-D type is equipped with air conveying chute, chute size is 330mm.

Why choose tongli Pulse jet bag filter dust collector?

- A Tongli Baghouse Dust Collector serves as an air pollution control apparatus that eliminates particulates from air or gas emitted from commercial processes or combustion for power generation. Renowned for its capability to manage high-volume dust loads, various grain sizes, and a substantial capacity for waste, Tongli Filters provides an array of models and options, ensuring they deliver the precise dust collector you require. Among their offerings are the Jet-Aire Baghouses and Jet Vent Dust Collectors, both acknowledged for their efficiency and versatility.

What are the adventages of tongli Pulse jet bag filter dust collector?

- Tongli’s Jet-Aire Baghouses emerge as an exemplary solution for solids processing and product recovery endeavors. Constructed as a standalone unit or through modular construction to accommodate unlimited airflow, these Pulse Jet Baghouse Dust Collectors excel even under the most severe conditions. They are meticulously designed to tackle the chemical and physical properties of the collected dust, guaranteeing an adequate air-to-cloth ratio for the application. Tongli also ensures the filter media is tailored for the application and that the interstitial velocity allows for effective filter cleaning.

- In contrast, Tongli’s Jet Vent Dust Collectors boast easy installation, operation, and maintenance. They deliver continuous fabric filtration for extended durations and are available in a wide spectrum of sizes, rendering the Jet-Vent one of Tongli’s most adaptable dust collectors. Engineered to handle a plethora of applications, from light to heavy dust loadings, they are also adept at managing different types of dust, ranging from fine to coarse particles.

Fertilizer plant pulse bag house filter dust collector structure

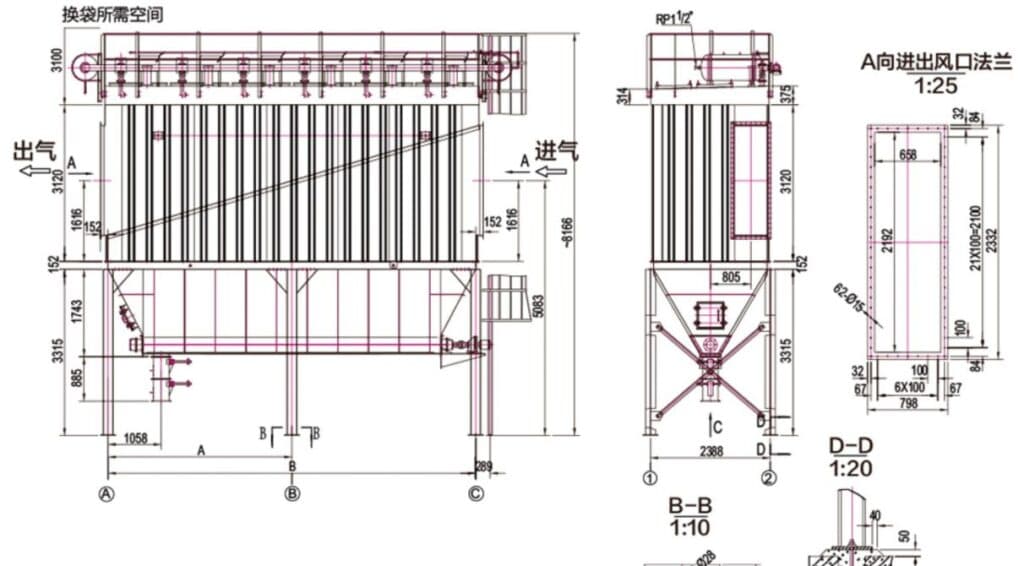

- The LPMC type gas shock pulse bag dust collector adopts a compartmental assembly structure and is composed of the dust collector body, inlet and outlet air box body, pulse injection dust cleaning device, ash hopper and ash unloading mechanism, compressed air pipeline system, etc.

- The dust collector body includes components such as a clean room, a filter room, compartment partitions, and access doors. The cleaning room is equipped with flower panels, poppet valves, and blow pipes, and filter bags and filter bag frames are installed in the filter room.

- The air inlet and outlet box includes the air inlet and outlet ducts and the middle partition. For single-row models, the air inlet and outlet boxes are on one side; for double-row models, the air inlet and outlet boxes are arranged in the middle of the two rows; the A series is smaller, with the air inlet in the ash hopper and the air outlet in the clean room.

Fertilizer factory dust collector filter bags self-cleaning working principle

- The pulse injection self cleaning device includes pulse valve, air bag, lift valve cylinder, solenoid valve, etc. The ash hopper and ash discharge mechanism include ash hopper, screw conveyor or air conveying trough and double-layer flap ash discharge valve.

- When the dust collector control system sends a dust cleaning control signal, the dust cleaning process is started. First, close the poppet valve of the first chamber to cut off the air flow through the filter chamber.

- The chamber exits the filtering state (offline), and then opens the pulse valve. The released high-pressure compressed air carries the air from the clean air chamber and sprays it into the filter bag at high speed, causing the chamber to exit the filtering state (offline).

- The filter bag suddenly expands and deforms, which shakes off the dust attached to the surface of the filter bag, and the dust falls into the ash hopper. After a period of settling, the controller opens the poppet valve and restores the chamber to the filtration state (online).

- Then start the cleaning process of other rooms in sequence until the entire cleaning cycle is completed.

How does Fertilizer Industrial pulse jet dust collection systems operation work?

- The dust-containing gas enters from the air inlet in the air inlet and outlet box of the dust collector, and is diverted to the ash hopper through the inclined partition.

- At the same time, the air flow speed slows down. Under the action of inertia, the coarse dust particles fall into the ash hopper, and the fine dust particles are deflected with the air flow.

- When it enters the filter chamber upwards, under the filtration effect of the dust cake on the surface of the filter bag, the dust particles are blocked on the outside of the filter bag.

- The purified gas enters the clean room from the inside of the filter bag, and is collected into the air outlet box through the opened poppet valve. It is discharged into the atmosphere through the system fan.

Harbor freight Bag filter housing collector dedusting self cleaning device

- The harbor freight pulse cleaning of tongli dust collector is controlled by the controller, which provides pressure difference control, timing control and manual control.

- The pressure difference control mechanism means that as the filtration process continues, the dust accumulated on the outer surface of the filter bag continues to accumulate, and the operating resistance of the dust collector gradually increases.

- When the resistance of the grizzly dust collector filter bag reaches the preset value, a control signal is issued to start dust cleaning. After receiving the signal, the dust collector repeatedly performs the cycle of “back-flushing and cleaning-sedimentation-filtration” room by room until the resistance of the dust collector drops to the set lower limit of resistance.

- The pressure difference control mechanism can always stabilize the dust collector resistance within a certain range, and the dust collector maintains the best dust removal efficiency and the lowest operating energy consumption.

- Timing control refers to arranging timing to implement backflush based on empirical values. It is usually used to deal with systems with relatively stable working conditions. Generally, the duration of the air-stop blowing in the grizzly dust collector filter bag and the time interval of the blowing in different chambers can be adjusted through operational observation during the trial operation stage.

- The operating temperature is ≤120°C; when using aramid needle felt (Nomex), the allowed operating temperature can reach 200°C; when exceeding the allowable temperature of each filter material, cooling measures should be taken before the flue gas enters the grizzly dust collector filter bag.

Allowable concentration at the entrance of harbor freight Bag filter housing dust collector

- Due to the special structure of this dust collector and the use of air-stop pulse jet cleaning (offline dust cleaning), the allowable concentration at the inlet is higher than that of traditional pulse jet dust cleaning (online cleaning) dust collectors. The dust concentration allowed in the inlet gas of series A (small) of this dust collector is 200g/m2 (standard), and other series B, C, and D can allow up to 1000g/m2 (standard).

High-performance industrial dust collectors model Description

- For example: our Tongli LPMC7B-558 represents B series single row 7 chambers, with a total filtration area of 558m2;

- LPMC: ultra-low emission gas shock pulse dust collector. LPMC2X5C-1195 represents a C series ultra-low emission gas shock bag dust collector with a double row arrangement, 5 chambers in each row, and a total filtration area of 1195m2.

Dust, fume, mist dust bag filter collection systems technical calculation and model selection:

1. Selection of bag filter dust collector air volume:

- The filtration wind speed refers to the amount of air passing through the filter material per unit area in unit time. The unit is m3/min/m2. If the area factor is removed, it is simplified to m/min.

- The filtration wind speed is a key parameter that affects the performance of the dust collector. It not only determines the size of the dust collector, but also has a great impact on the dust collector resistance, dust removal efficiency, dust cleaning efficiency and filter bag service life.

- The selection of filtration air speed and volume should be determined by comprehensively considering the application conditions, characteristics of flue gas and dust, temperature and humidity, dust concentration, dust cleaning method, selected filter material and other factors. LPMC air shock pulse dust collector generally recommends 0.7~0.9 m/min filter wind speed.

2. How to calculate the filter area of bag dust collector

- S=Q/(V.60)(m2)

S——Calculated value of total filtration area of dust collector, m2;

Q——The processing air volume of the dust collector, m3/h;

V——filtration wind speed of dust collector, m/min - Based on the filtration area value calculated by the above formula, check the model and performance table, select the LPMC air shock pulse bag dust collector model with a similar filtration area, and then calculate the filtration wind speed based on the filtration area of the dust collector; if the calculated filtration wind speed is within acceptable Within the selected range, the dust collector model can be determined.

3. Selection of dust collector filter bag materials

- The selection of filter material is closely related to the operating temperature. The allowable dust-containing gas temperature at the inlet of the dust collector is different, and the filter material is also different. When using film-coated polyester needle felt filter media, continuous use is allowed.

Should I buy a new bag house filter dust collector or used?

- The answer is buy a new one. one story short, a used bag filter is not cheap, while spending a little bit more and get a beand new efficient bag dust filter why not? While procuring used equipment may appear enticing initially, several factors necessitate consideration before arriving at a decision. These include the equipment’s suitability for your specific application, its capacity to handle the chemical and physical properties of the collected dust, and its compliance with regulatory requirements such as those set forth by the EPA. Conversely, acquiring a new dust collector ensures that the equipment is tailored to your specifications, guaranteeing optimal particulate collection at minimal operating costs.

How to do maintenance of industrial bag house filter dust collector?

- Maintaining your Baghouse Dust Collector is paramount to ensuring its efficiency and longevity. Regular maintenance can preempt common issues such as high differential pressure, filter bag wear, and dust leakage. It’s imperative to routinely inspect the cleaning system as well, as a malfunctioning cleaning system can precipitate a slew of problems, including premature filter bag failure and heightened emissions.

Does all bag filter looks square shape?

- Looking ahead, Tongli Filters is also delving into Cylindrical Filter Dust Collectors. These units offer continuous fabric filtration for prolonged durations, and devoid of internal moving parts, maintenance is minimized. They boast easy installation, operation, and maintenance, positioning them as an efficient and cost-effective solution for dust and product recovery.

- Baghouse Dust Collectors represent a formidable tool in combating industrial air pollution. They furnish a versatile and efficient solution for a myriad of applications, and with Tongli Filters’ diverse array of models and options, you’re bound to find the dust collector that aligns with your requisites.

- But To be honest round shape bag filter the only adventage is the dust will not stack to the corner, other that that, their’s no difference with the square shape bag house filter, because what deos the filtration is the filter bag not the outer case.

Notice to all customers before you place your bag house dust collector order from Tongli

- The order form must indicate the product name, model and quantity, and provide a brief process description of the dust removal system, treatment air volume, flue gas temperature, humidity, flue gas dust concentration, emission requirements, etc. Indicate whether the dust collector is used under positive pressure or negative pressure conditions. The installation location of the dust collector should also be stated, or information such as meteorological parameters and earthquake resistance level of the installation location should be provided.

- Dust collector supply scope: main air inlet flange – main air outlet flange space, components and accessories that make up the dust collector, mainly including: body, air inlet main pipe, air outlet main pipe, partition, filter bag, filter Bag frame, flower board, lift valve, ash hopper, pulse valve; gas source inlet pressure reducing valve, cylinder, gas distribution tank, injection system, dust cleaning controller, dust collector control box; inspection platform and steel ladder and other accessories The equipment is supplied in accordance with the contract requirements.

- The standard product matching filter material is coated polyester needle felt, with a temperature resistance of 120°C. According to the conditions of processing flue gas, the user can choose the filter material, and can also inform the properties and temperature of the flue gas and other parameters. Our company provides options.

- For dust cleaning control system, standard products are generally supplied according to the timing control method. Changes to the custom pressure cleaning control method must be specified.

- The height of the dust collector bracket is determined according to the design and the orderer’s requirements.

- If the process design requires the dust collector to be insulated, the supply will be negotiated separately. Anchor bolts for installation must be embedded in the foundation prepared by the user and are not included in the scope of supply.

- Large-type LPMC dust collector, supporting ash conveying equipment screw conveyor, if you need to use other ash conveying methods such as air conveying chute ash conveying, please indicate.

- The double-layer flap air lock valve (ash discharge valve) is supplied according to the system design needs and is not included in the standard equipment supply scope.

- Various pipelines other than the dust collector body, fans, air compressors, cables from the electric control cabinet to the terminals on the dust collector, power lines, power supply of the electric control cabinet, lighting of the dust collector, installation foundation of the dust collector, etc. Need to be provided by the user.

- Spare parts: It is recommended that the orderer order some spare accessories, such as pulse valves and filter bags, etc. The quantity of spare parts shall be determined by the orderer according to the application conditions.

- It is recommended that users install a rain-proof shed on the top of the dust collector, or they can entrust our company to process and install it;

- When the user chooses to install and debug the dust collector by himself, the company will send professionals to provide installation and debugging guidance. You can also entrust our company to be responsible for installation and debugging.

Conclusion:

Selecting the appropriate Baghouse Dust Collector for your application can be a multifaceted endeavor. It demands a profound understanding of your application, the nature of the dust you’re contending with, and the specific exigencies of your operation. At Tongli Filters, a team of experts stands ready to assist you in making the optimal choice. They’ll navigate you through the process, factoring in variables such as dust volume, particle size, process temperature, and air moisture content.