What is a Dicalcium Phosphate(DCP) Dryer drying system?

What is a Dicalcium Phosphate(DCP) and its application?

Dicalcium hydrogen phosphate is a colorless crystal that is easily soluble in water. Its main components are phosphate and calcium, with a relatively high content, usually 15% to 22%. Phosphorus is one of the essential elements for plant growth and can promote plant root development and improve fruit quality and yield. Calcium is one of the essential elements for maintaining normal plant growth and can enhance plants’ stress resistance and photosynthesis.

What are the 3 uses of Dicalcium Phosphate(DCP)?

Dicalcium Phosphate use as chemical fertilizer:

- Use as chemical fertilizer: Calcium hydrogen phosphate can be used as a phosphorus and calcium source for plants and is widely used in the production of vegetables, fruits, rice, wheat and other crops.

Dicalcium Phosphate as an acidic soil conditioner:

- As an acidic soil conditioner: Calcium hydrogen phosphate can reduce the acidity of the soil, improve nutrient utilization and soil fertility, thereby providing a more suitable environment for the growth and development of plants.

Dicalcium Phosphate as livestock and poultry feed:

- As livestock and poultry feed: Calcium hydrogen phosphate can be used as a supplement for phosphorus and calcium in livestock and poultry, effectively preventing calcium and phosphorus deficiency in livestock and poultry.

Why Dicalcium hydrogen phosphate(DCP) needs to be dried ?

Because the drying process of Dicalcium hydrogen phosphate(DCP) has a great impact on product quality, it needs to be dried. The drying process of calcium hydrogen phosphate consumes a lot of heat. Therefore, select the appropriate calcium hydrogen phosphate drying equipment and optimize the design of the calcium hydrogen phosphate drying process. , is of great significance for improving the thermal efficiency of calcium hydrogen phosphate drying process, reducing calcium hydrogen phosphate production costs and ensuring product quality. Due to the different processes in calcium hydrogen phosphate wet materials, special attention needs to be paid during the selection of calcium hydrogen phosphate drying equipment. Although there are many manufacturers of calcium hydrogen phosphate drying equipment in China, drying calcium hydrogen phosphate is difficult.

What are the types of Dicalcium hydrogen phosphate(DCP) dryer?

Flash dryer for small amount of DCP drying:

The heated air enters from the bottom of the drying tower at a suitable wind speed, and interacts with the wet materials added by the screw feeder to produce strong shearing, blowing, rotating, and crushing effects. During this process, the air transfers heat to the moisture in the material, causing the moisture in the material to vaporize and separate from the material due to absorption of heat, and is taken away by the air. The temperature of the air also decreases due to heat transfer.

Rotart dryer for large amount of DCP drying:

The DCP rotary dryer is equipped with a heater, which is usually heated using a gas burner or other methods. When the heater is working, it emits heat energy that is transferred to the air inside the dryer. The fan inside the dryer circulates the air. When the air flows through the heater, it is heated, and then is drawn by the fan into the drum, where it exchanges heat with the clothes, causing the moisture in the clothes to evaporate.

Why the (DCP)Dicalcium phosphate dryer burner is important?

Because DCP has very high drying temperature requirements, using a general direct natural gas burner or pulverized coal burner will destroy the composition structure of DCP. Therefore, in order not to destroy the chemical composition of calcium hydrogen phosphate and ensure the quality of the finished product, it needs to be used The ZJTL series (designed by zhejiang tongli heavy machinery) ducted hot air generation device controls the drying temperature at around 70~80 degrees and ensures drying efficiency.

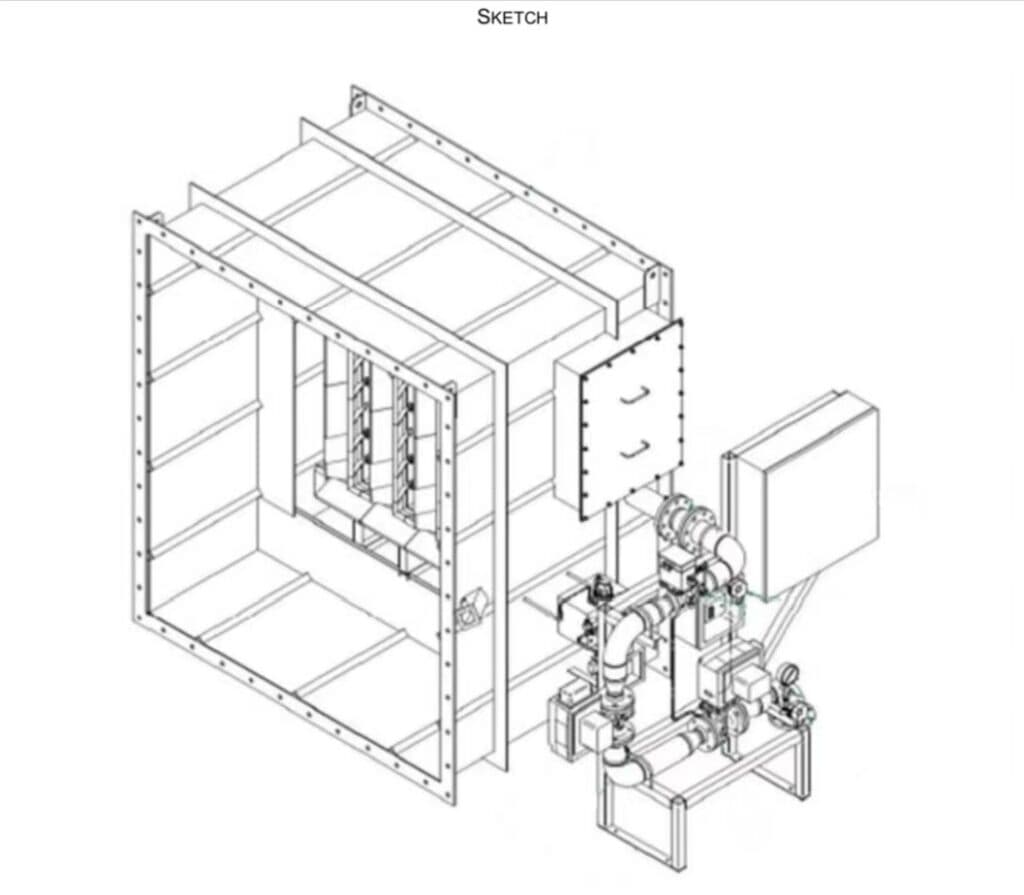

What is the struture and working principle of (DCP)Dicalcium phosphate dryer burner?

The ZJTL Series Indirect gas hot blast stove. In this type, the heat generated by natural gas combustion is transferred to the air through a heat exchanger, and the heated air is then blown into the room or used to heat objects. This method can avoid contamination and is suitable for materials that are temperature sensitive or do not allow contamination.

What is the production process of Dicalcium hydrogen phosphate?(DCP)?

Animal bone synthesis method:

This method first uses animal bones (such as cow bones) as raw materials, and undergoes deproteinization, acid invasion, alkali erosion and other steps to obtain degummed bone blocks. The small pieces of bones were then soaked in hydrochloric acid in an acid pool, neutralized with lime water, dried and inspected before being put into storage. The process also includes pelletizing and drying steps, with the final product packaged in double plastic bags.

Phosphoric acid and calcium-containing compounds method:

Calcium hydrogen phosphate is usually produced by reacting phosphoric acid with calcium-containing compounds such as limestone and dolomite. This process includes steps such as ingredients, mixing, reaction and crystallization, separation and drying. The calcium hydrogen phosphate crystals are separated by centrifuge and other equipment and dried.

metathesis method:

First let phosphoric acid react with soda ash to form a mixture of sodium dihydrogen phosphate and disodium hydrogen phosphate, and then add calcium chloride solution to carry out the metathesis reaction. After neutralization, precipitation, separation and washing, the finished product is obtained.

Extraction method:

Using superphosphate as raw material, calcium hydrogen phosphate is prepared through multi-stage water extraction, defluorination, lime milk neutralization and other steps.

Precautions for application of calcium hydrogen phosphate

1. When using, it should be applied rationally based on factors such as soil, crop type and variety, age, growth period, and degree of nutrient deficiency.

2. Since calcium hydrogen phosphate is acidic, attention must be paid to its use with alkaline fertilizers to avoid chemical reactions that may affect the growth and development of plants.

3. When using, attention should be paid to controlling the dosage. Excessive application will cause certain harm to the soil and environment.

Can Dicalcium phosphate(DCP) be used as fertilizer?

Dicalcium hydrogen phosphate itself is not directly used in agricultural production, but as an important raw material in fertilizer production. It is usually mixed with other raw materials by fertilizer production companies and processed into phosphorus-containing fertilizers, such as compound fertilizers. Calcium hydrogen phosphate is widely used in agriculture. It can be used as base fertilizer, top dressing and foliar spray fertilizer. It helps to improve the pH of the soil and improve the soil quality. Pay attention to the correct application amount, application time and application method. .

What is the difference between Dicalcium phosphate(DCP) and calcium carbonate?

In terms of element:

Calcium hydrogen phosphate is mainly composed of calcium ions and phosphate ions, while calcium carbonate contains calcium ions and carbonate ions.

In terms of solubility:

Calcium hydrogen phosphate is more soluble in water and difficult to be decomposed by gastric acid; calcium carbonate is relatively less stable and easily reacts under acidic conditions to form soluble calcium salts.

In terms of stability:

Calcium hydrogen phosphate has good chemical stability during storage and does not easily react with other substances; calcium carbonate is easily affected by humidity and deliquesces or weathers, which may lead to the loss of calcium contained in it.

In terms of Absorption speed:

The human body has a high absorption efficiency of calcium hydrogen phosphate, and its bioavailability is about 39%; calcium carbonate needs to go through a certain conversion process before it can be effectively utilized, and the utilization rate is about 25%. Calcium content. The calcium content of calcium hydrogen phosphate is generally about 30%, which is lower than about 40% of calcium carbonate.

Conclusion:

Calcium hydrogen phosphate is an important high-quality fertilizer that can effectively promote plant growth and development and improve soil fertility. When using it, you need to pay attention to the reasonable control of the application amount and use it in conjunction with alkaline fertilizers to achieve the best results.