Bucket Elevator Basics

Whether in industries such as chemical, mining, agriculture or fertiliser production, bucket elevators have shown great adaptability and efficiency. The bucket elevator is an efficient and reliable solution for vertical material handling, known for its outstanding versatility and customisability, and is widely used in bulk material handling systems across a wide range of industries. It is able to flexibly adapt to a wide range of material characteristics and conveying requirements, providing an efficient and reliable solution for a variety of vertical conveying tasks.

In this paper, we will take an in-depth look at the working principle of bucket elevators, their main types and their characteristics, and detail their application scenarios in different industries. We will also analyse the types of materials for which bucket elevators are suitable, as well as the key factors that need to be taken into account during the selection and use process. By gaining a comprehensive understanding of the performance and application scope of bucket elevators, readers will be able to better assess whether this equipment is suitable for their specific needs and thus make an informed choice.

How Bucket Elevators Work

The working principle of bucket elevator is to transport the material continuously upwards by using a hopper fixed to a traction device (such as a chain or belt). After the hopper is full of material at the bottom of the receiving area, it rises with the traction device, and when it reaches the top, it discharges the material by turning over or other means, and finally returns to the bottom to pick up the material again.

Common types of bucket elevators

The configuration of bucket elevator should be based on the application scene, material characteristics, the required power and lifting height and other factors for comprehensive consideration, in order to ensure that the performance and efficiency of the elevator to meet the actual needs.

Common bucket elevator types mainly include:

Centrifugal bucket elevator

Centrifugal bucket elevators utilise centrifugal force to throw material out of the hopper as it passes over the top pulley or sprocket. Centrifugal bucket elevators have higher operating speeds and greater hopper spacing than continuous bucket elevators. This high speed and large spacing optimises the filling of the material and reduces interferences between the hoppers.

Suitable materials: Suitable for materials that are not easily broken and are less abrasive, e.g. grains, plastic granules, cement clinker, etc.

Centrifugal bucket elevators can be divided into two types: belt type and single chain type.

Continuous bucket elevator

Unlike centrifugal bucket elevators, continuous bucket elevators have smaller hopper spacing and operate at lower speeds. This design allows material to flow from the back of the previous bucket for smoother discharge. In addition, the extended sides of the bucket gently guide the material into the discharge opening. These improvements make the Continuous Bucket Elevator particularly suitable for handling friable, abrasive and poorly flowing materials, with benefits including reduced material aeration and minimising the risk of breakage of friable materials.

Suitable materials: Suitable for friable and abrasive materials such as: coal, limestone, ores etc.

Continuous Elevators are available in belt, single chain or double chain designs.

Bucket Elevator Configuration Options Available

In addition to the configuration options, a variety of hopper styles are available, with the main considerations being material characteristics and hoist design.

- Material: The hopper material should be compatible with the material being conveyed and able to withstand the weight, impact and wear of the material. Common materials include:

- Carbon steel: for general material handling

- Stainless steel: for materials that are resistant to corrosion, heat and abrasion.

- Rubber: suitable for fragile materials

- Polyurethane: suitable for high-strength abrasive materials

- Shape: The shape of the hopper should be able to effectively load and unload materials, and minimise material spillage. Common shapes include:

- V-shaped: for bulk materials

- U-Shape: For less mobile materials.

- Round: for abrasive materials

- Capacity: The capacity of the hopper should be determined according to the conveying capacity of the elevator and the packing density of the material.

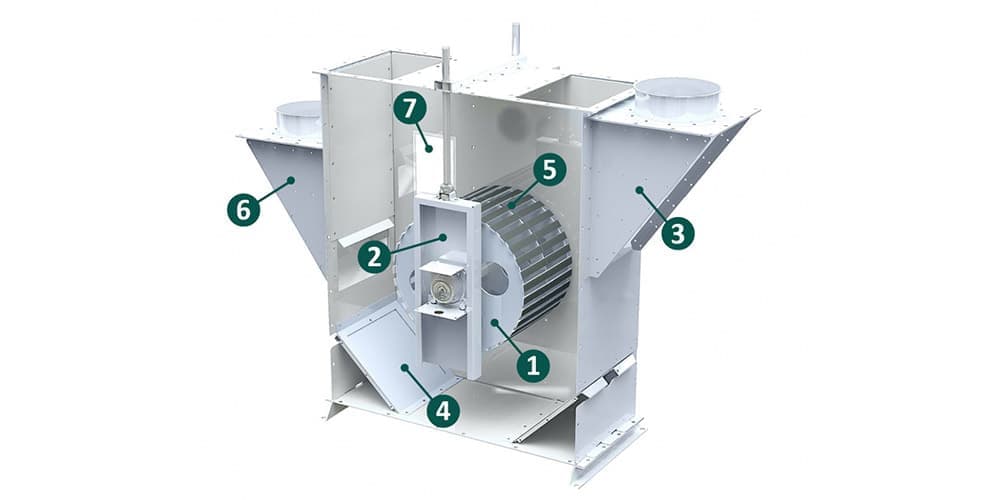

Other common configuration options for bucket elevators:

- Removable Top: For easy access and maintenance.

- Access Door: Provides easy access to the interior of the hopper for cleaning and maintenance.

- Reinforcements: Ensure the elevator can withstand the weight and impact of the material

- Horizontal and Vertical Reinforcements: Improve the stability and torsional strength of the hoist.

When choosing bucket elevator hopper, should take into account the characteristics of the material, the design of the elevator, the use of the environment and other factors, choose the appropriate material, shape and capacity of the hopper, in order to ensure the normal operation of the elevator and material conveying efficiency.

Bucket Elevator Application Areas

Bucket elevators are a versatile piece of bulk material handling equipment that is widely used in many industries due to its versatility and configurability. Common application areas include:

- Chemical industry: used to transport fertiliser, limestone, calcined coke and other materials.

- Building materials industry: for conveying aggregates, cement, sand, lime and other materials.

- Power industry: used to transport coal, fly ash, limestone and other materials.

- Metallurgical industry: used for conveying ores, metal powder and other materials.

- Grain processing industry: used for conveying grain, feed and other materials.

- Other industries: can also be used for tobacco, pharmaceuticals, plastics and other industries of material transport.

Bucket elevator applicable materials

Bucket elevator can handle a variety of bulk materials with different characteristics, including:

- Lightweight materials: e.g. grain, plastic pellets, wood chips, etc.

- Friable materials: e.g. coal, limestone, ores, etc.

- Abrasive materials: e.g. cement, fly ash, sand etc.

Bucket elevators are not recommended for wet, sticky or sludge-like consistency materials, which can cause discharge problems and equipment clogging.

Precautions for selecting bucket elevator

The selection of bucket elevator should be based on the material characteristics, lifting height, conveying capacity and other factors for comprehensive consideration, select the appropriate model and configuration. When selecting bucket elevator, the following matters should be noted:

- The selected bucket elevator should be able to meet the performance requirements of material conveying, including lifting height, conveying capacity, material characteristics and so on.

- The configuration of the selected bucket elevator should meet the specific application requirements, such as transmission mode, hopper material, hopper shape, discharge mode, etc..

- The selected bucket elevator should come from a reputable manufacturer with a perfect after-sales service system.

Bucket elevator is a kind of efficient and reliable bulk material conveying equipment, in the selection and use of the process need to pay attention to the above matters, in order to ensure its normal operation and smooth conveying of materials.

TONGLI Bucket Elevator: Over 60 years of experience to meet tough challenges

With more than 60 years of experience in customising bucket elevators, TONGLI is committed to providing customers with high-quality, reliable bulk material handling solutions. Whether you need to convey dry, dusty materials or heavy, more challenging products, TONGLI can customise a bucket elevator solution to meet your needs.

The TONGLI bucket elevator advantage:

- Experienced: More than 60 years of experience, accumulated deep knowledge of bucket elevator design, manufacturing and application.

- Leading technology: Continuous innovation, research and development, the application of advanced technology to ensure excellent product performance.

- Customised service: according to your material characteristics, conveying needs and application environment, tailor-made exclusive bucket elevator solutions.

- Reliable and Durable: Adopting high-quality materials and parts to ensure the durability of the products.

- Perfect after-sales service: Provide timely and professional after-sales service to ensure the normal operation of your equipment.

TONGLI bucket elevator is widely used in chemical industry, building materials, electric power, metallurgy, grain processing and other industries, which can be used for conveying bulk materials such as chemical fertiliser, limestone, calcined coke, aggregate, cement, sand, coal, fly ash, ore, metal powder, grain, feed and so on.