Rotary Dryer Services In High Demand In Aging Frac Sand Dryers

In recent years, although demand for frac sand is nowhere near its peak more than a decade ago, the industry is experiencing a degree of recovery, which has led to a strong demand for rotary dryer services.

Fractured Sand Dryer Maintenance Considerations

As equipment ages, many plant managers are working to ensure that their dryers are not only mechanically sound, but also ready to handle potential increases in demand. Here are some key considerations for getting aging frac sand dryers back up and running.

Inspections and Audits

Operators and maintenance personnel should regularly inspect the rotary durm dryer and address any issues that arise. If the equipment has not been thoroughly evaluated for some time, it is recommended that the equipment be audited by the original equipment manufacturer (OEM) or other qualified service professional to assess its mechanical condition. This type of inspection provides a more in-depth evaluation of the equipment and provides valuable baseline data for future maintenance programs.

Dryer Alignment

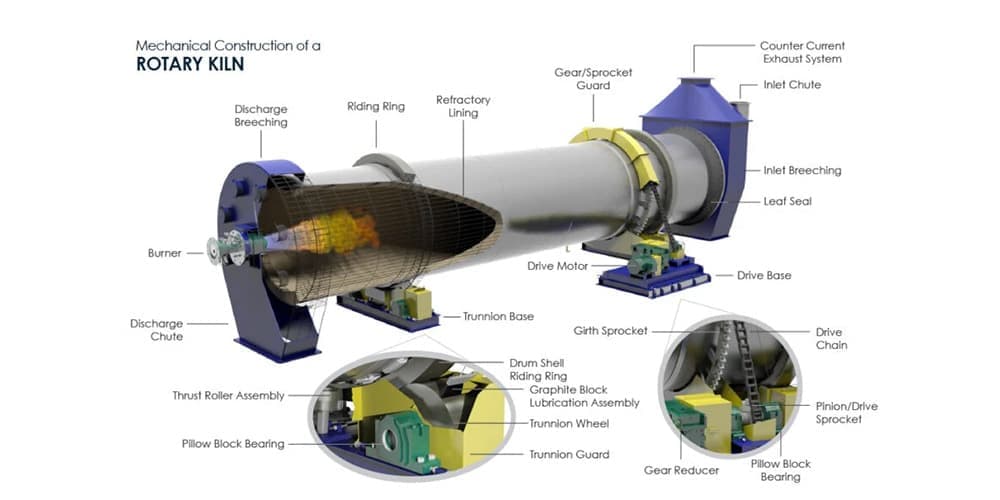

One of the most frequently required procedures for aging dryers is alignment. After years of operation, rotary dryers can lose alignment, especially if there are underlying mechanical problems. Wear on tires, support or thrust rollers, and gears may indicate an alignment problem. Using a laser tracking system, a service professional can quickly and accurately perform a realignment. It is recommended that an alignment be performed after any major component, such as a tire or support wheel, has been replaced or repaired.

Dryer Training (Float)

While alignment focuses on correctly positioning the support wheels, training concentrates on properly positioning the drum between the thrust rollers. This measurement is often referred to as “floating” because ideally, the drum will float evenly between the thrust rollers without over-running on either the uphill or downhill thrust rollers. With training, proper float can be achieved by adjusting or “tilting” the support bearings to affect the direction and longitudinal thrust of the drum.

Tire and Support Wheel Condition

Tire and support wheel life can vary significantly depending on operating and maintenance conditions, so many tires and support wheels in the frac sand industry may still be in good condition. When support wheels are incorrectly tilted, damage may occur that significantly reduces their life. Therefore, plant managers should have an expert assess the condition of tires and support wheels to ensure their reliability.

Grinding worn tires and support wheels

Surface wear on tires and support wheels can often be addressed by grinding. Grinding is a reconditioning process in which worn components are ground or resurfaced to reveal a new surface similar to the one underneath the wear.TONGLI strongly recommends alignment after grinding; if the root cause of the wear is an incorrect and uncorrected alignment, the wear will immediately reappear on the newly ground component.

Gear and Pinion Replacement

At this age, ring gears should still be in good condition; quality gears can last up to 25 years. However, if the gears are not properly lubricated and maintained during operation, wear may occur. Early wear may be addressed with simple adjustments, but in most cases, replacement is recommended.

Upgrading Burners

Burner technology has evolved over the past decade, resulting in significant improvements in burner efficiency. As a result, upgrading to newer models of burners can save fuel and energy and help dryers operate more efficiently.

Rotary Drum Shell Problems

Drum shell problems are not uncommon for frac sand dryers, especially when using lightweight equipment that cannot withstand the specific challenges of drying frac sand. Wear and tear on the shell (and other components that come into regular contact with the sand) is a major concern. Therefore, the shell, feed zone, and dryer interior (flights) should be inspected for wear and any worn components should be replaced as needed.

Seal Maintenance

Seals can wear out over time, allowing air to enter the dryer, which ultimately reduces process efficiency. Worn seals should be repaired and/or replaced as needed.

Inlet and outlet fittings

Inlet and outlet fittings may also wear over time, especially given the abrasive nature of frac sand. Depending on the severity of the wear, the joints may need to be repaired or replaced. For added protection, abrasion-resistant linings may also be implemented.

Spare parts for frac sand dryers

TONGLI also recommends maintaining a stock of wear critical components and other spare parts to minimize potential downtime in the event of a failure.

Wear critical components to be stocked

Wear critical parts are those parts without which the dryer cannot (or should not) operate, meaning that in the event of a failure, the entire operation will come to a standstill until the component can be replaced. In order to avoid excessive downtime, rotary dryers should be supplied with the following wear critical components:

- Flyers

- Support wheels and bearings

- Replacement thrust roller assemblies

- Replacement pinion assembly

- Graphite blocks

- Replacement of vane seals and vane seal plates

Preventive Maintenance Considerations

TONGLI recommends that manufacturers take preventive measures to address any problems encountered with their dryers or their components, as this is much cheaper than fixing the problem when it occurs, especially if the failure occurs unexpectedly. A preventive maintenance program, including annual inspections by the OEM, is critical to maintaining process efficiency, minimizing unnecessary downtime and maintenance costs, and maximizing dryer life.

Conclusion

As aging equipment degrades and demand increases in the frac sand industry, plant managers must consider the maintenance needs of their equipment to maintain the integrity of their production and maintenance facilities. Plant managers should pay particular attention to dryer alignment, the condition of tires and support wheels, potential shell issues, and any worn components.

We understand the special needs of frac sand drying equipment and have extensive industry experience and expertise. Whether you need routine maintenance, emergency repairs, or are looking for solutions to improve the performance of your equipment, TONGLI can provide you with the highest quality service.

Contact the TONGLI customer service team today and let us help keep your frac sand drying equipment running at peak performance, increasing productivity and reducing operating costs. We look forward to working with you to meet the industry’s challenges and achieve sustainable development.